Jewels In Watches

Maybe your like

This system provides the same benefits as any other jewel, mainly reducing friction and wear, but it also provides an extra advantage of being able to equalize the effects of friction between horizontal and vertical positions. That is to say when the watch face is vertical the balance wheel is exposed to the same amount of friction as when the watch face is horizontal. This helps the watch keep better time. These are 4 of the jewels you would find in a 7 jewel pocket watch and in every modern watch. As an added bonus the cap jewel system can be fit into a shock protection system, but the cap jewel itself doesn’t provide any of that protection.

The escapement

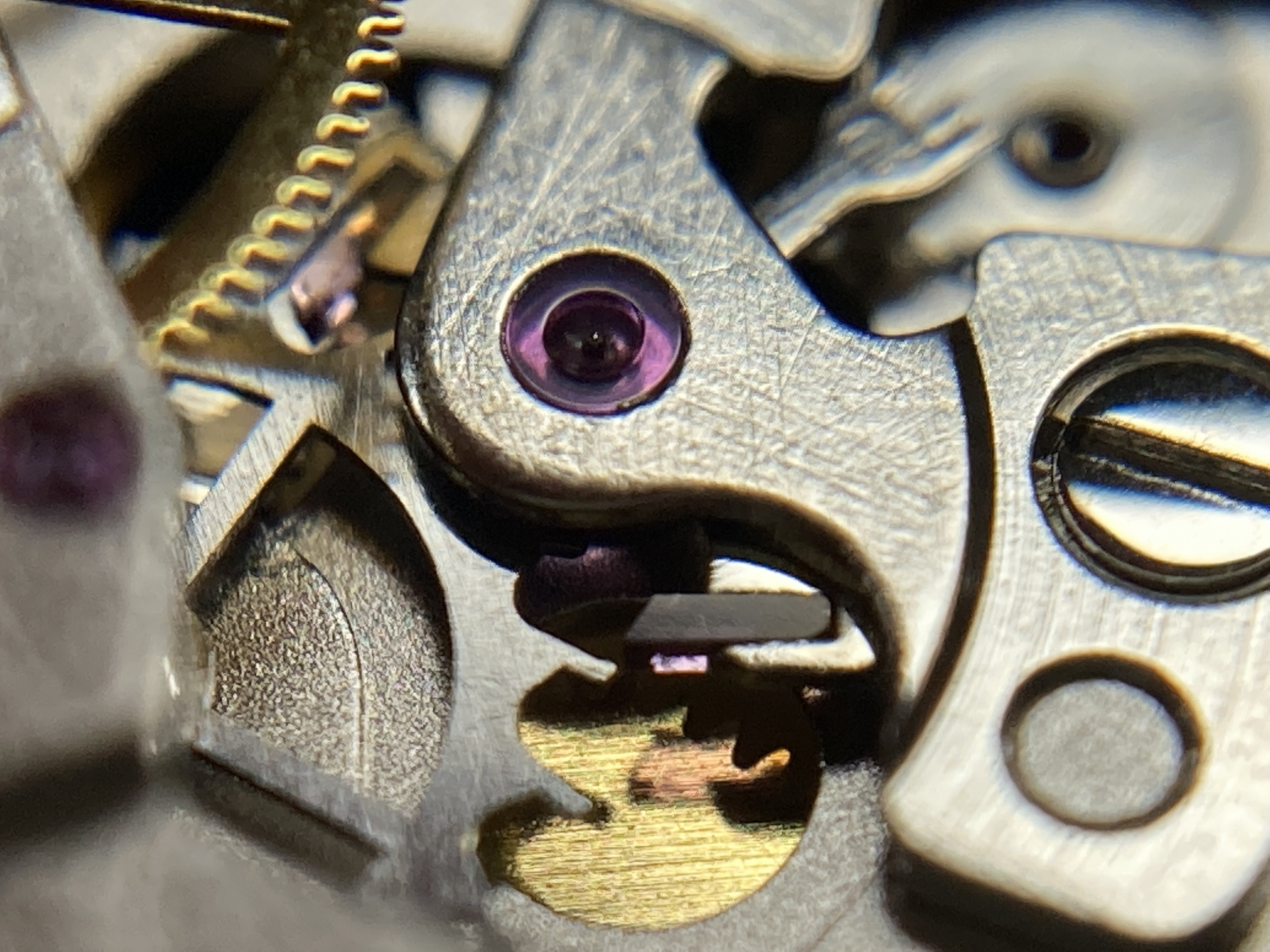

The escapement is the mechanism which delivers energy to the balance and keeps it oscillating so the watch will run. The Swiss lever escapement, used in most modern watches is a beautiful mechanism but it has some downsides, namely friction. This is why the co-axial escapement is considered to be a superior design because it eliminates the sliding friction of the escapement. There are 3 essential jewels in the escapement.

They are a roller jewel which is attached to the roller on the balance and two pallet stones that receive the impulse from the escape wheel. The roller jewel is the part that receives the impulse from the pallet fork. It is made from ruby to keep it from developing a flat spot due to the repeated impacts (at least 432,000 per day.) The pallet “stones” (that’s what watchmaker’s call the rectangular stones in the pallet fork) have a special geometry which uses sliding motion to convert the rotational energy of the escape wheel into a back and forth motion which is used to propel the balance wheel when the opposite end of the fork (the notch) strikes the roller jewel. These are the other 3 jewels in a 7 jewel pocket watch. In the photo of the escapement, you will notice that the pivot of the pallet fork arbor is also supported in jewels. These would be brass bushings in a 7 jewel watch but are usually jewels in all modern watches.

The gear train

The jewels in the gear train all share similar properties. The bottom of the jewel is flat. It has a hole drilled in it and the top has an oil sink (or little bowl) to hold the lubrication. Occasionally the train wheels will have capped jewels like the balance but usually, they just have one jewel on each side, like the one pictured on the pallet fork. Two jewels for each of the wheels in the train (escape wheel, fourth wheel, third wheel, and center wheel) will bring the count to 17. A manual wind watch is considered “fully jeweled” if it has jewels all the way through to the center wheel.

Additional Jewels

A high-grade pocket watch with 23 jewels would have capped jewels on the escape wheel and jewels for the barrel arbor and barrel contributing 6 additional jewels.

Automatic Watches

The automatic winding mechanism often takes more abuse than the escapement so jewels are really important, however, some brands have released watches without any jeweled bearings in the automatic mechanism. This is far less common today than it was 25 or 30 years ago. The typical modern automatic watch has 17 jewels in the base movement and additional jewels in the automatic mechanism. The location and total count depend on the design. If the automatic mechanism has an oscillating weight with an axle, like many Rolex calibers, then the axle is usually supported by two jewels. If the mechanism uses ball bearings no jewels are necessary for the oscillating weight. The typical winding train in the automatic mechanism consists of 2 reversers and a driving wheel each of which will have 2 or more jewels. In the case of the Rolex automatic winding mechanism pictured (caliber 2235), the driving wheel actually utilizes 3 jewels bringing the total number of jewels in the automatic module to 9.

Other Jewels

The base movement for the Rolex 2235 actually has 22 jewels and the total movement has 31. The base movement has capped escape wheel pivots, 2 jewels for the barrel, and a 3rd jewel to support the sweep seconds pinion. Add those to the 9 in the automatic device and you have 31 jewels. Interestingly enough there are also 4 more jewels in the date mechanism which don’t seem to be counted, probably because they don’t meet the strict rules of the NIHS for “functional jewels.”

In a chronograph mechanism, you might find jewels for some of the extra wheels needed to provide that complication. Occasionally you find a minute wheel post that is made from ruby if the manufacturer was afraid that a brass or steel post might not last. The more complications you add, the more jewels you will need. The Patek Philippe 6301P: Grande and Petite Sonnerie with minute repeater and dead seconds has 95 jewels! Every last one of them is there to help reduce friction (very important in a watch like that) and to make sure the components will last so you can hand the watch down to the next generation.

Today there are very few watches on the market that don’t have enough jewels. As a watchmaker, I rarely see a component in a modern watch that is unnecessarily worn, simply because the manufacturer chose not to use a jewel where they could have, however, I do see this in old pocket watches all the time. So, today, jewels aren’t so much a measure of quality as they were in days of old, but they are still really important. We do see some material innovation which is replacing jewels. The most notable being the use of ball bearings in automatic watches in place of an axle with jewels and silicon pallet forks which don’t need any jewels at all because the silicon has a “self-lubricating” characteristic which provides a very low coefficient of friction even without lubrication. So, with only a few exceptions: In order for your watch to keep running day after day without wearing out, it needs jeweled bearings. They reduce friction and prolong the life of your watch.

Tag » What Is Jewels In A Watch

-

What Are Jewels In A Watch? A Complete Guide - Ben's Watch Club

-

What Are The Jewels In A Watch For?

-

Jewels In Watch Movements: Their Purpose In Timekeeping ...

-

What Are Jewels In Watches? - Precision Watches

-

What Are Watch Jewels & Are They Necessary? - WatchBox

-

What Are Watch Jewels: A Complete Guide

-

Jewel Bearing - Wikipedia

-

The Number Of Jewels In A Watch Movement Indicates Value, Or ...

-

What Do Jewels In A Mechanical Watch Mean? – Tufina Official

-

Rubber B Presents: What Are The Jewels In A Watch For?

-

Jewels | WatchTime - USA's No.1 Watch Magazine

-

What Do Jewels Do In A Watch? - Uniform Wares

-

What Are Jewels In Watch Movements? - Millenary Watches