10 Technologies/Methods For Controlling NOx & SOx Emissions From ...

Maybe your like

It’s a known fact that whenever a machine is operated to perform some work, it is impossible to achieve 100% work efficiency because of various reasons such as friction, heat dissipation etc.

When it comes to ship’s engine, a massive mechanical structure with several moving parts, the work efficiency achieved out of it is 70-85% for suitable running condition.

The combustion of gases inside the engine emits harmful smoke into the atmosphere which leads to loss in the system and pollution of the marine environment.

Annex VI of MARPOL deals with restricting the amount of harmful emissions from ships’ main propulsion system and provides guidelines for substances such as Sox and NOx.

Several technologies have been introduced to reduce the level of harmful emissions in ship’s exhaust system.

We have enumerated 10 such different technologies and systems used onboard ships to comply with MARPOL for reducing marine pollution.

Reducing NOx emission

The presence of NOx in marine engine’s exhaust emission is due to high combustion temperature which reacts with nitrogen in the air supplied for combustion. Read more about it here.

Following are the methods to reduce NOx emission from ship:

1. Humid Air Method: In this method, water vapour is mixed in the combustion air before supplying it to the cylinder. Air from the T/C blower is passed through a cell that humidifies and chills the hot air taking moisture from the cooling water until air saturation is achieved. Generally saline sea water is utilized in this method by heating it with jacket water and turbo charger heat, and the left over brine is disposed back to the sea. This method can achieve reduction of NOx by 70-80%.

2. Exhaust Gas Re circulation (EGR): As the name suggests, some amount of engine exhaust gases are send back to the scavenge space to mix up with the air to be supplied to cylinder for combustion. This reduces the oxygen content of the air and hence reduces formation of NOx.

3. Water Injection and Water emulsion: In this method, water is added to reduce the temperature of combustion leading to low NOx emission. In water emulsion, fuel is blended with water and in water injection a separate fresh water injector is mounted in the cylinder head which injects water. This method has a drawback of increasing the specific fuel oil combustion with reduction in NOx by only 20-45%.

4. High Scavenge Pressure and Compression Ratio: With high scavenge pressure and compression ratio, large amount of air can be introduced inside the cylinder to lower combustion temperature and NOx emission.

5. Selective Catalytic Reduction: The SCR is the most efficient method to reduce NOx emissions from ships (up to 90-95% of reduction). In this method, low sulphur fuel oil is used and exhaust temperature is maintained above 300 deg C. The exhaust gas is mixed by water solution of urea and then it is passed through catalytic reactor. The only disadvantage of SCR is its expansive installation and operating cost.

6. Two Stage Turbocharger: ABB’s latest two stage turbocharger can reduce the exhaust temperature in the intercoolers and also the NOx content in the emitted exhaust.

7. Engine Component Modification: It is better to design an engine which has a property to reduce the NOx formation during combustion process rather than investing on expensive secondary measures. Integration of slide valve type fuel injector with almost zero sack volume eliminates any chance of fuel dripping and after burning, leading to cylinder temperature and NOx formation.

New designs like Green Ultra long stroke engine from MAN (GME series) with reduced mean piston speed gives more time for excess air and proper combustion to lessen NOx formation.

Reducing SOx Emission

SOx or sulphur oxides are formed during combustion process in the engine because of presence of sulphur content in the fuel. Read More about it here.

Following are the methods and technologies used to reduce sulphur emission from marine engines.

8. Use of Low sulphur fuel oil: It is expensive but most commonly used method to comply with Annex VI of MARPOL while entering emission controlled Area or ECA.

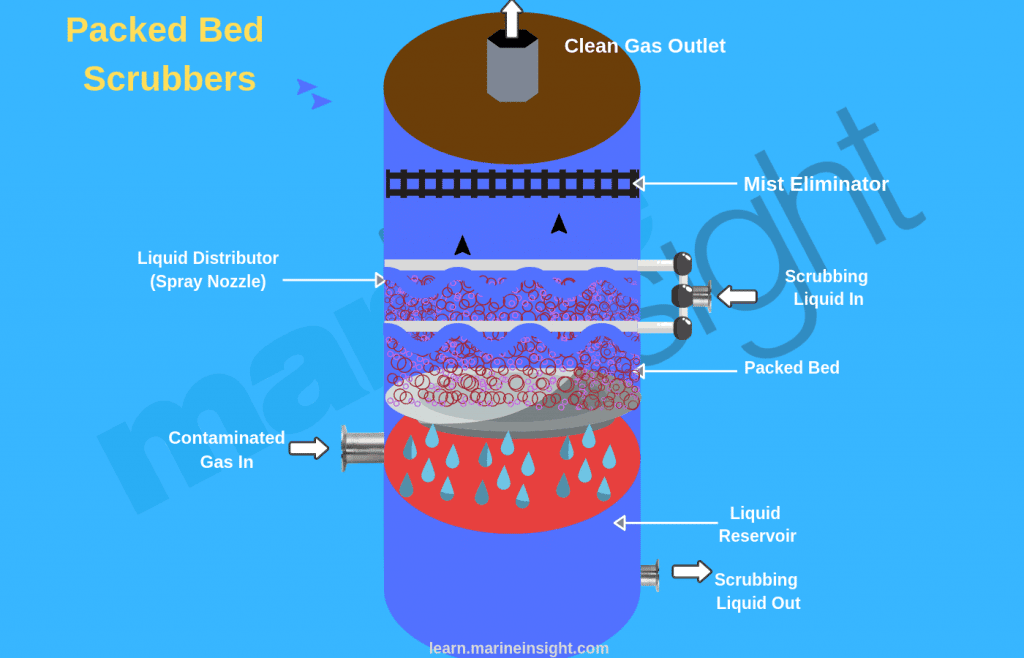

9. Exhaust Gas Scrubber Technology: The exhaust gas from the engine is passed through the scrubber tower where a liquid is showered over it. Fresh water blended with caustic soda (NaOH) is used as a scrubbing liquid which reduces the SOx to 95%. The scrubbing water is then sent to a water treatment effluent emulsion breaking plant after which it can be discharged overboard.

10. Cylinder Lubrication: Good quality cylinder lubrication along with efficient control systems such as Pulse or Alpha lubrication systems can neutralise the sulphur in the fuel and reduce SOx emissions from the engine.

Do you know any more methods or technologies to reduce Sox and Nox emissions from marine diesel engines? Let us know.

You may also like to read –

- 2020 Sulphur Compliance: Vessel Preparation And Implementation Guidelines

- Impact of North American Emission Control Area (ECA) on the U.S and the Shipping Industry

Disclaimer : The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

Related Posts

Disclaimer : The information on this website is for general purposes only. While efforts are made to ensure accuracy, we make no warranties of any kind regarding completeness, reliability, or suitability. Any reliance you place on such information is at your own risk. We are not liable for any loss or damage arising from the use of this website.

Related Articles

⚓️ Enhance Your Knowledge. Prevent Accidents. Stay Safe at Sea.

1. eBooks for Engine Department

Master machinery operations, troubleshooting, and safety procedures with expertly written guides tailored for marine engineers. Prevent costly breakdowns and onboard accidents through practical knowledge.

👉 Explore Engine Department eBooks

2. eBooks for Deck Department

Sharpen your seamanship, navigation, and cargo-handling skills with real-world case studies and practical insights designed for deck officers and cadets.

👉Discover Deck Department eBooks

3. eBooks on Electrical Fundamentals & Issues

Understand marine electrical systems, identify potential faults, and prevent onboard electrical failures with step-by-step explanations from industry experts.

👉Get Electrical eBooks

4. Pocket Guides for Quick Reference

Compact, handy, and loaded with essential checklists—perfect for on-the-go reference during operations and emergencies at sea.

👉 Browse Pocket Guide eBooks

5. Combo Packs to Save Big

Access multiple expert eBooks at discounted prices. Ideal for professionals seeking complete safety and operational knowledge across various ship departments.

👉 Grab Combo Pack Offers

6. Digital Maritime Courses – Learn at Your Own Pace

Upgrade your competence with Marine Insight Academy’s online courses. Learn from industry professionals anytime, anywhere, and become a safer, smarter seafarer.

👉 Join Online Maritime Courses

Subscribe To Our Daily Newsletter

Enter email hereBy subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Tag » How To Reduce Nox Emissions

-

Nitrogen Oxides: Pollution Prevention And Control

-

Nitrogen Oxides (NOx) Control Regulations - EPA

-

NOx Emission Reduction Strategies - Pollution Online

-

6 Tips For Reducing NOx Emissions | CECO Enviromental

-

[PDF] REDUCING NOX EMISSIONS ON THE ROAD

-

Reducing NOx Emissions During Combustion

-

6 Tips For Improving Efficiency And Reducing NOX - Process Heating

-

Many Ways To Cut Ship NOx Emissions - Airclim

-

[PDF] How To Reduce Emission Of Nitrogen Oxides [NOx] From Marine Diesel ...

-

Reducing NOx Emissions Using Fuel Staging, Air Staging, And ...

-

Effective Reduction Of NOx Emissions From Diesel Engine Using Split ...

-

Controlling Nitrogen Oxide Emissions From Industrial Sources

-

[PDF] Reducing NOx Emissions From Ship Exhaust - Alfa Laval

-

NOx And CO2 Emissions From Trucks: What Trade-off?