5 Symptoms Of A Bad Motor Mount (and Replacement Cost In 2022)

Maybe your like

A vehicle’s engine produces a lot of vibration when running. Without specific components called motor mounts (or engine mounts), the vibration would transmit to the entire car and make it very uncomfortable its occupants.

Learning to recognize the symptoms of a bad motor mount quickly will save you a lot of trouble in the long run. While the cost of engine mount replacement isn’t cheap, ignoring it can end up being a lot more expensive.

Table of Contents

Bad Engine Mount Symptoms

Motor mounts secure your engine while absorbing its vibrations. When they start to fail, they typically show several warning signs that can help you catch problems early.

#1 – Excessive Vibration

One of the earliest and most noticeable signs of failing motor mounts is increased vibration throughout your vehicle. You may feel this through your steering wheel, seats, or floorboard (particularly at idle).

These vibrations and shaking often become more intense when accelerating or when the engine is under load. While some vehicle vibration is normal due to all the moving parts within an engine, a properly working motor mount should minimize these sensations.

If you notice your car suddenly vibrating more than normal or if the vibration changes intensity at different engine speeds (RPM), this strongly suggests at least one motor mount is failing.

#2 – Impact Noises From the Engine Bay

It’s common to hear various clunking, banging, or knocking sounds coming from the engine area with motor mount failure. These noises are typically most noticeable during normal movement of the engine (such as when accelerating, braking, or shifting gears).

This happens because worn mounts allow excessive engine movement, causing it to shift and bump against other components. Engines are designed with a certain amount of buffer space are components. Bad motor mounts often causes the engine to move beyond that buffer space.

These types of sounds may be particularly loud when starting the car, or when driving on rough roads where the engine movement is more pronounced.

#3 – Engine Movement During Startup and Shutdown

Starting and stopping your engine creates significant torque, which normally should be controlled by your motor mounts. When these mounts are failing, you’ll notice excessive engine movement (referred to as “engine rocking”), particularly during startup and shutdown.

To see this in action, open your hood and watch the engine while someone else starts the engine. This movement can sometimes occur shifting between Drive and Park, or when quickly pressing and releasing the gas pedal (revving the engine).

While a small amount of movement is normal, anything more than about an inch of movement in any direction indicates mount problems.

#4 – RPM-Dependent Vibrations

Different engine speeds create different vibration patterns, and worn motor mounts often reveal themselves through vibrations that occur at specific RPM ranges.

You might notice the vibration is particularly strong between 800-1200 RPM (idle speed or slightly above), or becomes more intense around 2000-3000 RPM during acceleration. These vibrations might seem to come and go as you drive, directly corresponding to your engine speed.

Pay attention to whether the intensity changes when you’re accelerating versus maintaining a steady speed, as this variation is a pretty good sign of mount issues.

#5 – Engine Sagging or Tilted

A noticeable sag or tilt of the engine to one side is another sign that you have a motor mount issue. This misalignment might be visible when looking at your engine bay, but it can also show up as uneven gaps around your hood or fenders. It not only looks strange, but this misalignment can cause strain on belts, hoses, and electrical connections.

When examining your engine, check if it sits level and if all the mounting points appear to be at the same height. Any noticeable drooping or tilting, especially on one side, is a dead giveaway for mount failure.

This symptom often appears gradually but becomes worse over time. If one mount fails, the others will have to support additional weight and a chain reaction will soon follow.

#6 – Transmission Shifting Problems

Bad motor mounts can affect your transmission by allowing excessive engine movement that disrupts the precise alignment needed for smooth shifting. Harder shifts, delayed engagement when putting the vehicle in gear, or clunking sounds during gear changes can all be a result.

This happens because the engine and transmission need to be properly aligned for the transmission to shift correctly. If you notice these symptoms along with other mount-related issues, the shifting problems are likely being caused or made worse by failed motor mounts rather than an action problem with the transmission.

While troubleshooting may be much more difficult, failed motor mounts are a much better diagnosis than a major transmission issue.

Related: 5 Signs of Transmission Mount Failure

#7 – Squeaking or Rubber Noises

A distinctive squeaking or rubber-on-rubber noise can indicate deteriorating motor mounts, particularly if they’re the rubber type rather than hydraulic. These sounds often occur when you accelerate or brake, or when shifting between Drive and Reverse.

The noise happens because the rubber components within the mount have started to break down and separate, allowing surfaces to rub against each other that shouldn’t be in contact. This squeaking is often more noticeable in cold weather when rubber components are less flexible, and it often gets louder as the mounts continue to deteriorate.

#8 – Component Damage in Engine Bay

In severe cases of motor mount failure, you might notice damage to various engine bay components. This is sometimes the result of of our #2 symptom (Impact Noises) above.

This can include worn or damaged radiator hoses, frayed belts, stressed electrical connections, or marks where the engine has contacted other parts. The most common areas to check are around the radiator fan shroud, belt areas, and any places where hoses or wires connect to the engine.

Look for signs of rubbing, unusual wear patterns, or broken clips and brackets. This type of damage indicates that the engine has been moving excessively and needs immediate attention.

Motor Mount Replacement Cost

Best places to order parts? See: 19 Best Online Auto Parts Stores

Motor mount replacement costs vary significantly based on your vehicle make, model, and where you have the work done. Labor typically makes up the majority of the expense since accessing motor mounts often requires lifting the engine and removing other components.

Here’s what you can expect to pay:

- Parts Cost – Motor mounts themselves generally run between $75 to $200 each. OEM (Original Equipment Manufacturer) mounts are usually more expensive than aftermarket options, but their quality and fit are usually more reliable.

- Labor Cost – Due to the complex nature of the job, labor charges range from $300 to $600. Some luxury or hard-to-service vehicles might cost even more due to their design and the extra time needed to access the mounts.

- Total Cost – For a single motor mount replacement, expect to pay between $375 to $800. However, mechanics often recommend replacing mounts in pairs or sets since they typically wear at similar rates. A complete set of mounts could cost $1,000 to $1,600 including labor.

Remember that these prices can vary based on your location and chosen repair shop. Dealerships within a major city are typically going to have the highest rates while independent shops in the suburbs or rural areas will be lower.

In some cases, diagnostic fees may apply if you’re unsure which mounts need replacement. While it might be tempting to choose the cheapest option, investing in quality parts can prevent premature failure and the need for repeated repairs.

Read Also: Strut Mount Replacement Cost

Common Causes of Engine Mount Failure

Age and Normal Wear

Motor mounts naturally deteriorate over time and mileage. The rubber components lose elasticity, and hydraulic mounts can develop leaks. Most mounts last 5-10 years (60k to 120k miles) under normal conditions, though this varies by vehicle.

Oil Contamination

When engine oil leaks onto rubber mounts, it causes them to break down prematurely. Even small, slow leaks significantly speed up deterioration as the rubber becomes saturated and loses its cushioning ability.

Aggressive Driving

Hard acceleration, sudden braking, and aggressive cornering create excessive stress on motor mounts. Engine modifications that increase power output can also overwhelm stock mounts, leading to early failure.

Impact Damage

Hitting curbs, deep potholes, or road debris can crack or break motor mounts. This typically affects the metal brackets rather than the rubber components. Even minor impacts can create cracks that worsen over time.

Environmental Factors

Extreme temperatures and road salt accelerate mount deterioration. Cold weather makes rubber brittle and prone to cracking, while heat causes deformation. Corrosive materials can weaken the metal components.

Can I Drive with a Bad Motor Mount?

No, you shouldn’t drive with a worn or damaged motor mount, even though your car may still operate. Bad motor mounts create a cascade of problems that get worse over time.

The excessive engine movement stresses your remaining good mounts and can damage critical components like belts, hoses, and wiring harnesses. In severe cases, a completely broken mount could allow your engine to shift dramatically during braking or acceleration, potentially causing serious damage or affecting vehicle control.

If you must drive to a repair shop or get home, keep your speed moderate, avoid sudden movements (EASY on the gas and brake pedals), and take the shortest safe route to get to your destination. But it’s important to get it fixed as soon as possible to avoid the potential of more serious issues (and expenses).

How a Motor Mount Works (and Types)

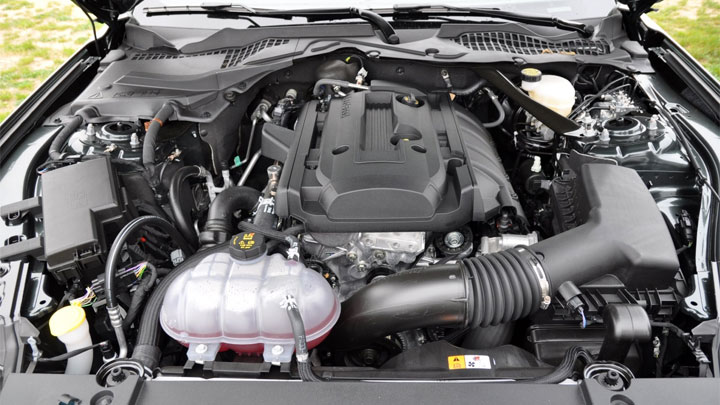

Motor mounts are essential components that secure your engine to your vehicle’s frame or subframe. Most vehicles use three to four mounts for the engine, plus additional mounts for the transmission.

These mounts serve two main functions: they hold the engine firmly in place and reduce vibrations throughout your vehicle.

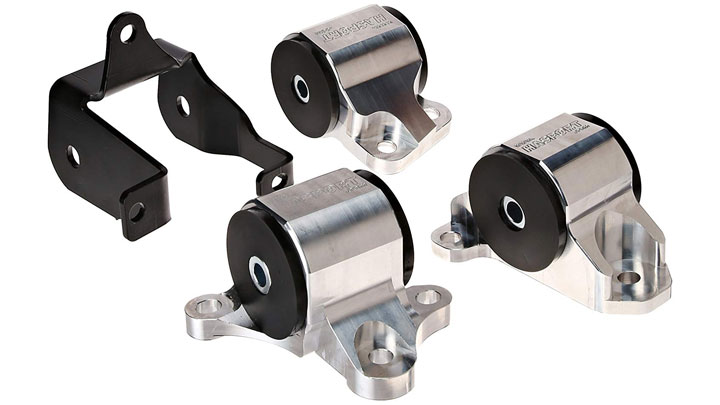

The basic design of a motor mount consists of two metal brackets connected by a cushioning center section. This design prevents metal-to-metal contact between your engine and frame, significantly reducing the transfer of engine vibrations to your vehicle’s body and passenger compartment.

Common Types of Motor Mounts

Conventional Rubber Mounts

The most basic and common type of motor mount uses solid rubber as the cushioning material. These mounts are durable, cost-effective, and work well for most daily drivers. While they’re the simplest option, they typically need replacement sooner than other types and may transfer more vibration to the cabin.

Hydraulic Mounts

Found in many modern vehicles, hydraulic mounts contain fluid-filled chambers that provide superior vibration dampening. These mounts adjust to different engine loads and speeds, offering better performance than conventional rubber mounts. While more expensive, they typically last longer and provide a more comfortable driving experience.

Active Motor Mounts

Used primarily in luxury and high-performance vehicles, active mounts contain electronic sensors and controls that adjust mount stiffness based on driving conditions. They can firm up during aggressive driving for better handling or soften during idle for maximum comfort. These are the most expensive type but offer the best performance.

Hybrid Mounts

These mounts combine features of both rubber and hydraulic designs, offering a middle-ground solution. They typically use both rubber cushioning and fluid chambers, providing better vibration control than conventional rubber mounts while being more affordable than fully hydraulic options.

Without properly functioning motor mounts, engine vibrations would transfer directly to your vehicle’s frame, potentially causing damage to components and creating an uncomfortably rough ride. The mounts also prevent your engine from shifting during acceleration, braking, and cornering, which helps maintain proper alignment of belts, hoses, and electrical connections.

See Also: Reasons Your Car Shakes When Accelerating

- Author

- Recent Posts

- 7 Symptoms of a Bad Flexplate (and Replacement Cost) - Mar 4, 2026

- How to Turn Off the “Keep Hands on Steering Wheel” Warning (By Car Brand) - Feb 25, 2026

- Can You Mix Different Brands of Motor Oil? (What Actually Happens) - Feb 20, 2026

Tag » How To Replace Motor Mounts

-

9 Steps To Replacing Motor Mounts | Mobil™

-

How To Replace Motor Mounts In Your Car - YouTube

-

How To Replace A Motor Mount Or Transmission Mount - YouTube

-

How To Check And REPLACE A Bad Engine Mount - YouTube

-

How To Replace A Motor Mount In Your Car - YouTube

-

How To Know When To Replace Motor Mounts - European Car Repair

-

How To Replace An Engine Mount | YourMechanic Advice

-

Replace Motor Mount - Advance Auto Parts

-

How To Replace Motor Mounts: DIY Removal And Installation

-

5 Signs You Need To Replace Worn Engine Mounts

-

How To Replace Engine Mounts – Step By Step - Transgold

-

Mercedes W123 Motor Mount Replacement - IFixit Repair Guide

-

Engine Mounts: Here Are 5 Reasons You Need To Replace Them