Differential Pressure Transmitters: How Do They Help In Flow ...

Maybe your like

Flow measurement is basically the process of determining the fluid flow in a plant or an industry. This measurement can be done with the help of various devices, such as positive displacement meters, differential pressure transmitters, Coriolis, magnetic meters, etc. However, differential pressure transmitters are being used on a large scale for flow measurement in various industries. These flowmeters can either be used as gas flowmeters or liquid flowmeters. Different types of differential pressure transmitters are used for based on the application requirements. In this post, we will shed some light upon the working of differential pressure flowmeters and their types.

How Do Differential Pressure Transmitters Measure the Fluid Flow?

The working of differential pressure (DP) flowmeters is based on the Bernoulli’s principle. Here is the working principle of a differential pressure flow transmitter explained in a few, easy-to-understand steps:

- Step 1: A compression is created in the pipe by the differential pressure flowmeter.

- Step 2: A pressure drop is created in the flowmeter because of this constriction.

- Step 3: This pressure drop increases with the increase in the fluid flow.

- Step 4: The upstream and downstream pressures are routed to the differential pressure transmitter by impulse piping.

- Step 5: This differential pressure is then measured by the transmitter and fluid flow is determined.

What are the Types of Differential Pressure Flowmeters?

Based on the measurement, different types of differential pressure flowmeters are used. Here are a few types of DP flowmeters.

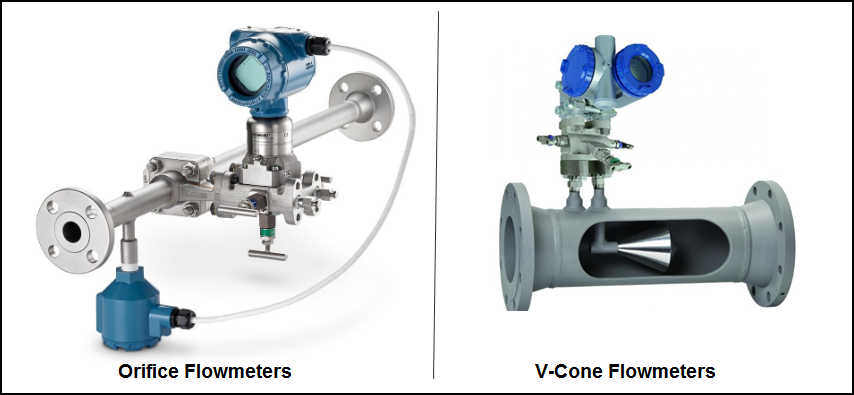

- Orifice Flowmeters: The orifice flowmeters consist of a flat metal plate, with an opening. This flat plate is installed in a circular pipe, and is perpendicular to the flowing fluid. When the fluid passes through the opening (orifice), a restriction is caused, which decreases the pressure and increases the velocity of the flow. The pressure between the pipe flow stream and the orifice is measured by a differential pressure transmitter.

- Pitot – Static Tube Flowmeters: These flowmeters consist of annular tube, pitot tube, and static pressure ports. The pitot tube converts the kinetic energy of the fluid flow into potential energy to determine the local velocity at a point in the flow stream.

- V-Cone Flowmeters: As the name suggests, these flowmeters consist of a V-shaped cone element. It is placed in the center of the pipe to create an annular space for passing the fluid. This conditions the fluid flow and creates a differential pressure. It enables easier and less noisy measurement of the differential pressure as compared to that done by orifice technology. The pressure before the cone and after the cone is measured with the help of a differential pressure transmitter.

There are other types of flowmeters too, such as elbow, wedge, spring-loaded variable aperture, nozzle, venturi, and laminar flowmeters. Hope the post helped you in understanding how the differential pressure transmitters work. Also, the information about the different types of differential pressure flowmeters will help you select the right one for your flow measurements. If you are confused in selecting the right type of transmitter for your application, you can seek advice from an expert. The Transmitter Shop is one such expert, which provides wide varieties of reliable differential pressure transmitters, such as Foxboro transmitters, and Rosemount transmitters.

Related Posts

- What are the Steps Involved in Calibrating Pressure Gauge?

- All Important Questions on Reconditioned Transmitters Answered

- Is Remanufactured Transmitter a Better Option than a New One?

- Differential Pressure Transmitters: How Do They Help in Flow Measurements?

- 3 Whats that Explain How Often You Should Calibrate Pressure Transducer

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- Things to Check before Buying a New Pressure Transmitter

- A Look at Various Types of Industrial Transmitters – Part II

- A Look at Various Types of Industrial Transmitters Part I

- All Questions on Smart Transmitters and their Calibration Answered

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitter

- Factors of Consideration When Choosing Pressure Transmitters

- 5 Most Popular Pressure Transmitter Technologies

- Tips to Improve the Performance of Pressure Sensors

- Factors to Consider When Choosing a Pressure Transmitter Manifold

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducer

- Rosemount 3051S vs 3051C Transmitter – What is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitter for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & how does it work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- Testing Pressure Gauges: Processes of Verification Test and Functional Test

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Fluid Flow Isolation Techniques for Pressure Instrumentation

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- 4-20 mA Transmitter Wiring: Understanding 2-Wire, 3-Wire, and 4-Wire Systems

- Flow Measurement Challenges in Subsea Operations

- How PLC Control Systems Work with Process Transmitters in Industrial Automation

- Common Process Measurement Challenges in Industrial Instrumentation

- Measurement Errors, Drift and Calibration Challenges in Industrial Processes

Tag » How Do Differential Pressure Transmitters Work

-

Differential Pressure | Yokogawa SE Asia

-

How Does A Differential Pressure Transmitter Work - ABB

-

Differential Pressure Transmitter Working Principle - Inst Tools

-

Differential Pressure Transmitters Explained | RealPars

-

Beginner's Guide To Differential Pressure Transmitters

-

Differential Pressure Transmitter Explained - YouTube

-

How Differential Pressure Transmitters Measure Level - WIKA Blog

-

Pressure Transmitter Basics: Types, Functions, And Working Principle

-

Differential Pressure Sensors | The Design Engineer's Guide - Avnet

-

What Does A Differential Pressure Sensor Do? - Mid-West Instrument

-

Differential Pressure Measurement Transmitter | TTS

-

Transmitters | Differential Pressure - Dwyer Instruments

-

How Does A Pressure Transducers Work? - Omega Engineering

-

An Introduction To DP Transmitters