How To Build A Wooden Wishing Well - BuildEazy

Maybe your like

Introduction & description

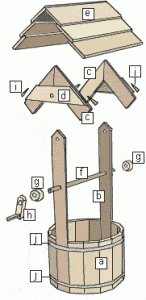

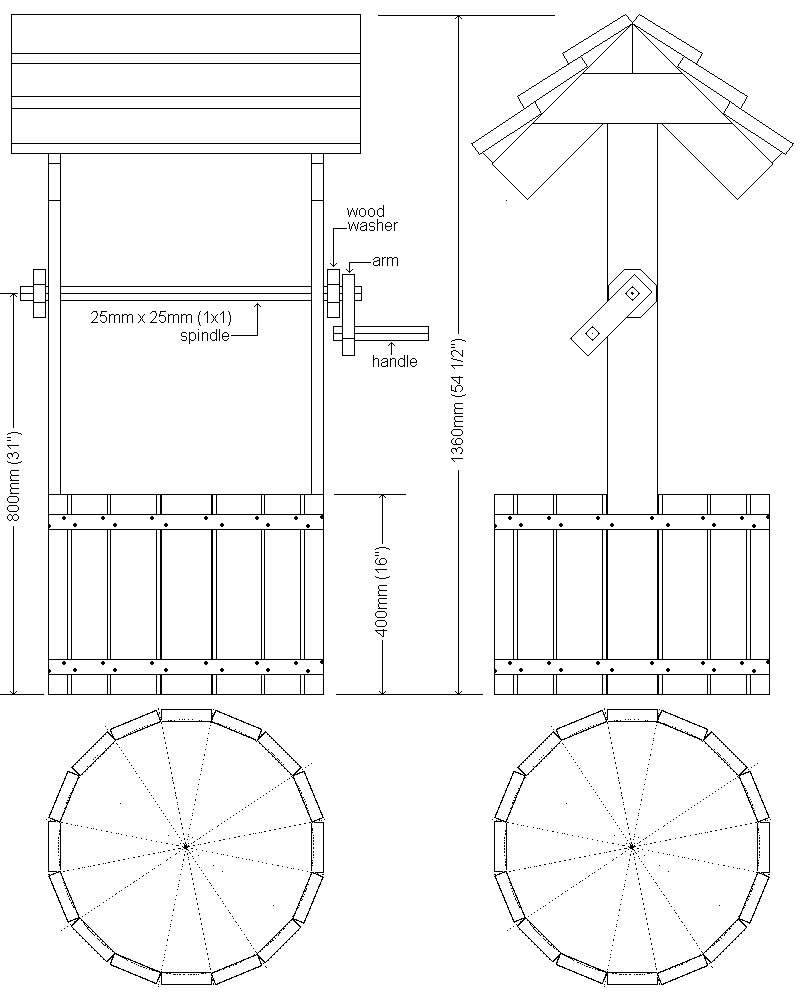

This medium-size wishing well stands approximately 1400mm (4′-8″) high and 600mm (2ft) wide. It is a cross between a small planter and a full-size wishing well, and can be used either as a planter box or a garden ornament. This wishing well is a lot of fun to build.

The lumber used in this project is pressure-treated board. You can use a different type of wood as long as it is suitable for exterior use. For the most part, 100mm x 25mm (1×4) stock is used, the exception being the roof boards which are 150mm x 25mm (1×6), and the spindle and spindle handle which are 25mm x 25mm (1×1).

Wishing Well Plans

$5.00The well stands 1400mm (4′-8″) high and is 600mm (2ft) wide. The cutting list in the downloadable file gives a drawing of every piece of woodAdd to cart

|

The measurements are given in both millimetres and inches. The millimetres are given first followed by inches in brackets. For example: 100mm x 25mm (1×4).The metric measurements are not an exact match to their imperial equivalents for rounding off purposes, so use one or the other.

Schematics and materials

Schematics

What you will need

Note: All lumber should be pressure-treated or suitable for exterior use.

• 12 meters (40ft) of 100mm x 25mm (1×4) board;• 5 meters (17ft) of 150mm x 25mm (1×6) board;• 1 meter (39″) of 25mm x 25mm (1×1) wood;• 4 meters (13.5ft) of 30mm (1 1/4″) galvanized metal strap;• 26 exterior type 50mm (2″) long screws;• 16 exterior type 75mm (3″) long screws for the roof boards;• two 10mm (3/8″) galvanized bolts 60mm (2 1/2″) long, and• around 70 of 25mm (1″) galvanized flathead nails.

Alternatives: The 150mm x 25mm (1×6) board for the roof can be replaced with 100mm x 25mm (1×4) board. If so, make adjustments when working out the lumber quantities.Also, the roof boards do not have to overlap, as shown in the plan – they can be butted up (made flush) to each other. It really boils down to taste.

The cutting list

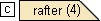

14 pieces of 100mm x 25mm (1×4) lumber @ 400mm (16″) long. The palings and the extended palings form the wishing well wall.

2 pieces of 100mm x 25mm (1×4) lumber @ 1200mm (4ft) long overall, with a 45 degree point at one end. The extended palings continue up from the wall and support the roof.

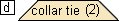

4 pieces of 100mm x 25mm (1×4) lumber @ 400mm (16″) long, cut back one end at a 45 degree angle.

2 pieces of 100mm x 25mm (1×4) lumber @ 400mm (16″) long, cut back both ends at a 45 degree angle .

6 pieces of 150mm x 25mm (1×6) lumber @ 700mm (28″) long.

1 piece 25mm x 25mm (1×1) lumber @ 1000mm (39″) long. Cut both the spindle and handle from this piece.

2 pieces 100mm x 25mm (1×4) @ 100mm (4″) long with a 35mm (1 3/8″) hole in the center of both pieces. These pieces can be cut from off-cuts and are used as washers on the spindle. They can be left square or rounded.

1 piece 50×25 (1×2) @ 180mm (7″) long with a 35mm (1 3/8″) hole at each end. This piece fits on the spindle and takes the handle. It can be made from off-cuts.

4 wedges 0 to 20mm (0 to 3/4″) thick and 120mm (5″) long. These can be cut from off-cuts and are fixed to the topside ends of the rafters.

4m (13.5ft) of 30mm (1 1/4″) galvanized strap or similar.Note: If this strap is not available in your location other options include galvanized water heater restraining strap, or even galvanized wire fixed with appropriate staples.

FYI, palings (in the context of this content) are the upright (vertical) members of the wishing well wall.

The plans

Instructions – Steps 1 to 2

Step 1. Cut all the members

- Cut out all the members (pieces) to the dimensions as shown in The cutting list, on page 3.

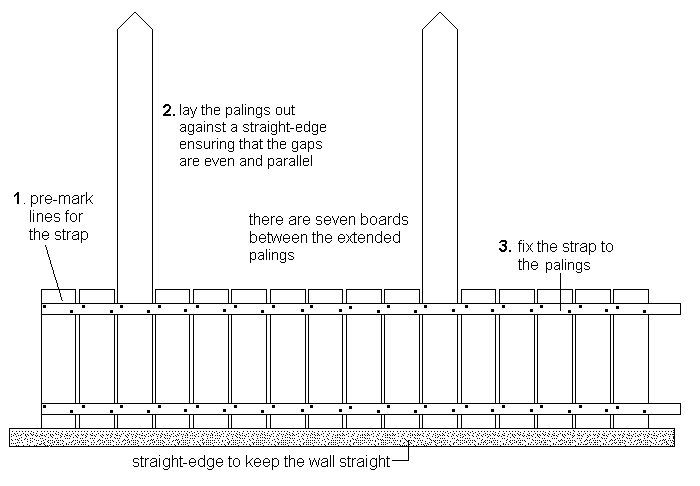

Step 2. Mark and lay out the palings

- Measure 40mm (1 1/2″) down from the top and the same amount up from the bottom of all 14 palings (a) and mark a line.

- Also mark corresponding lines on the 2 extended palings (b), making a total of 16 marked boards altogether.

- Lay all the palings (a) and extended palings (b) next to one another on an even surface, with the bottoms against a straight edge to keep them in line.

- When laying down, ensure that there are 7 palings (a) in between the 2 extended palings (b). (See diagram below.)

Note: The gap measurements are given on the next page.

Instructions – Steps 3

Step 3. Space the palings

- The distance of the gap between the palings is crucial to forming a good circle. In this instance, the palings are 25mm (1″) thick so the gap will be 10mm (3/8″). If the palings are a different thickness, then the gaps will also need to be different. (See The Gap Equation on the next page for a detailed explanation.)

- If you use palings of a different thickness, use the Gap Equation on the next page to establish the gap size. That is, divide the thickness of the paling by 2.6

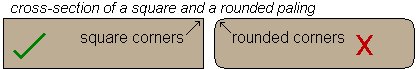

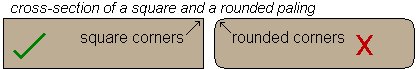

Note: This gap formula will only work if the corners of the palings are square. If the corners are rounded the equation will not work.

- There is however, another method that does work. There is a way you can use lumber with rounded corners, as explained on page 8.

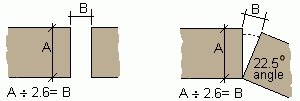

The gap Equation

- The distance of the gap between the palings is crucial to forming a good circle. The gap, or spacing between the palings (a) should be the thickness of the wall board divided by 2.6.

For example: The thickness of the palings in this project is 25mm (1″).

Therefore: 25mm (1″) divided by 2.6 = 9.6mm or near enough to 10mm (3/8″). Hence the gap or spacings between the palings in this project will be 10mm (3/8″).

Note: The width of the wall paling has no bearing on the size of the gap. Whether the palings are 100mm x 25mm (1×4) or 200×25 (1×8), the gap will be the same. Only the thickness and the total number of palings matter. 14 palings (a) and 2 extended palings (b) make 16 palings in all. Each paling is at a 22.5 degree angle to the next, and 22.5 degrees times 16 is 360 degrees, which is a circle. Get it? Yep!

Note: The above formula will only work if the corners of the boards are square. If the corners are rounded the equation will not work.

But, there is a way you can use lumber with rounded corners, as explained on the next page.

The gap for lumber with rounded corners

- The equation to find the gap needed between the palings (to form a circle) is easy enough to work out if the lumber used has square corners.However, sometimes lumber has slightly rounded corners, and that is a horse of a different color.You must measure the gap when two palings are together, as if they were fixed in place on the wall.That scenario can be emulated by using a pattern as described below.

- The wall of this wishing well is not really a circle as such, it is a 16 sided polygon called a hexadecagon. Actually, a regular hexadecagon because all the sides are the same.

- So! make a pattern (as below) depicting two adjacent sides of a regular hexadecagon (16 sided polygon).Then butt the edges of two paling pieces together at the vertex (where the angle changes).The gap (at the top) between the two pieces is the gap that all of the palings will need to be spaced when making up the wall.

1. Using a piece of board or plywood or just about anything, cut an angle along one edge running 22.5 degrees off the edge line, as shown in fig.1 above. That is the pattern.

2. Using two off-cuts of paling, butt them together where the angle changes on the pattern, as shown in fig.2 above. The gap (at the top) between the two pieces of paling is the gap you will need to space all of the wall board pieces to form the circle for the wall.

Instructions – Steps 4 to 5

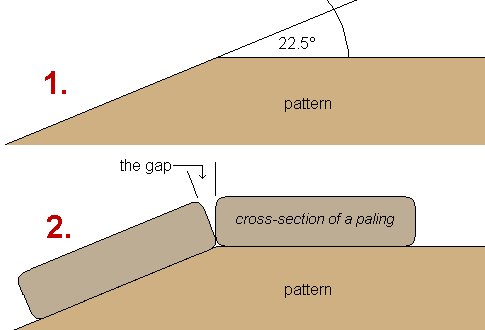

Step 4. Fixing the metal strap and forming the circle

- Now that the science lesson is over, and the 14 palings (a) and 2 extended palings (b) are all lying in place on even surface with correct gaps, the 2 metal straps (j)can be nailed to the palings using two 30mm (1 1/4″) galvanized flathead nails at each meeting. Place the straps 40mm (1 1/2″) down from the top of the palings and 40mm (1 1/2″) up from the bottom.

- See the drawing on page 5 for layout.

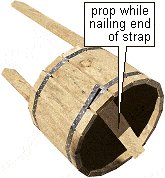

- When the metal straps are nailed in place, flip the structure over and commence rolling it up. If the gaps between the palings are correct, it will form an accurate circle. Overlap the metal straps by 1 paling and nail off. Use a prop to hold everything rigid while nailing the end of the strap.

Step 5. The roof

- On a flat surface, make up the two roof frames by first screwing the rafters (c) together at the apex, then screwing the collar ties (d) to the rafters (c). Then nail the wedges (i) to the bottom topside of each rafter. See fig 1 below.

- Next, sit the two roof frames upright on top of the two the extended palings (b) and clamp in place. Drill a 10mm (3/8″) hole through the collar tie (d) and the extended wall board (b) and fasten together using one 10mm (3/8″) galvanized bolt 60mm (2 1/2″) long for each roof frame. See fig 2 below.

- Screw the roof board (e) to the rafters (c), beginning with the lower roof board (e) overhanging the rafters (c)by about 20mm (3/4″). Then fix the other roof boards (e) in place, ensuring that they are evenly spaced. See fig 3 below.

Final instructions – Step 6

Step 6. The handle and spindle

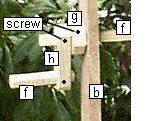

- Drill two holes in the extended palings (b) 800mm (31″) up from the bottom. Make the hole size 35mm (1 3/8″) or big enough so that the spindle (f) can easily go through it. We have chosen treated 25mm x 25mm (1×1) square timber for the spindle because it is more readily available and easier to obtain than treated doweling (round rod).

- Make up two wooden washers (g), by drilling 35mm (1 3/8″) holes in the center of blocks made up from two pieces of off-cuts 100x100mm x 25mmmm thick (4″x4″x1″thick). The outside edge of the washer can be rounded or just left square-shaped.

- In a similar fashion make up the handle arm (h). Drill a 35mm (1 3/8″) hole each end of a 50×25 (1×2) @ 180mm (7″) long piece of lumber.

- Now put it together. Thread the spindle (f) through the holes in the extended palings (b). Slide a washer (g)on at each end about 5mm (1/4″) away from the extended palings (b) and then put a screw through each washer (g) fastening it to the spindle (f).

- Next, slide the handle arm (h) along the spindle (f) until it is against a washer (g), and fasten to the spindle (f) with a screw. Cut off excess spindle (f) and use this as the handle which will also be fastened in the handle arm (h) with a screw.

Note. No floor

This wishing well is sturdy enough to not require a floor. It can be used just as a garden ornament, planters can be placed inside it, or it can be placed over an existing plant.

Don’t forget to throw a 5 cent coin in and make a wish!Mmmmmm – Better make that 10 cents. Inflation you know.

All done. Eazy with a “Z”!

Tag » How To Build A Wishing Well

-

How To Make A Wishing Well - YouTube

-

Cheap DIY Wishing Well - YouTube

-

Building The Antique Wishing Well Part 2 - YouTube

-

DIY Wood Wishing Well - YouTube

-

15 Free Wishing Well Plans With Detailed Instructions - Its Overflowing

-

How To Make A Wishing Well In 3 Easy Parts - WikiHow

-

How To Build A DIY Wishing Well - Woodworking - Pinterest

-

Wooden Wishing Well Plans | MyOutdoorPlans

-

25 DIY Wishing Well Plans: How To Build A Wishing Well

-

10 Easy DIY Garden Wishing Wells You Can Make Today

-

Make A Simple Wishing Well : 6 Steps (with Pictures) - Instructables

-

How To Build A Wishing Well Planter | HowToSpecialist

-

Wishing Well Plans Free | Free Garden Plans - How To Build Garden ...