How To Flush AC System After Compressor Failure?

Maybe your like

Table of Contents

- Introduction

- Safety First

- Step-by-Step Guide to Flushing Your AC System

- 1. Recover Refrigerant:

- 2. Remove the Failed Compressor:

- 3. Drain Residual Oil:

- 4. Attach the Flushing Kit:

- 5. Flush the System:

- 6. Flush Each Component Separately:

- 7. Drain the Flushing Solvent:

- 8. Dry the System:

- 9. Replace Components:

- 10. Vacuum the System:

- 11. Recharge the System:

- Conclusion

- Discover more:

- Visit Forum

- Visit Our Friendly Website

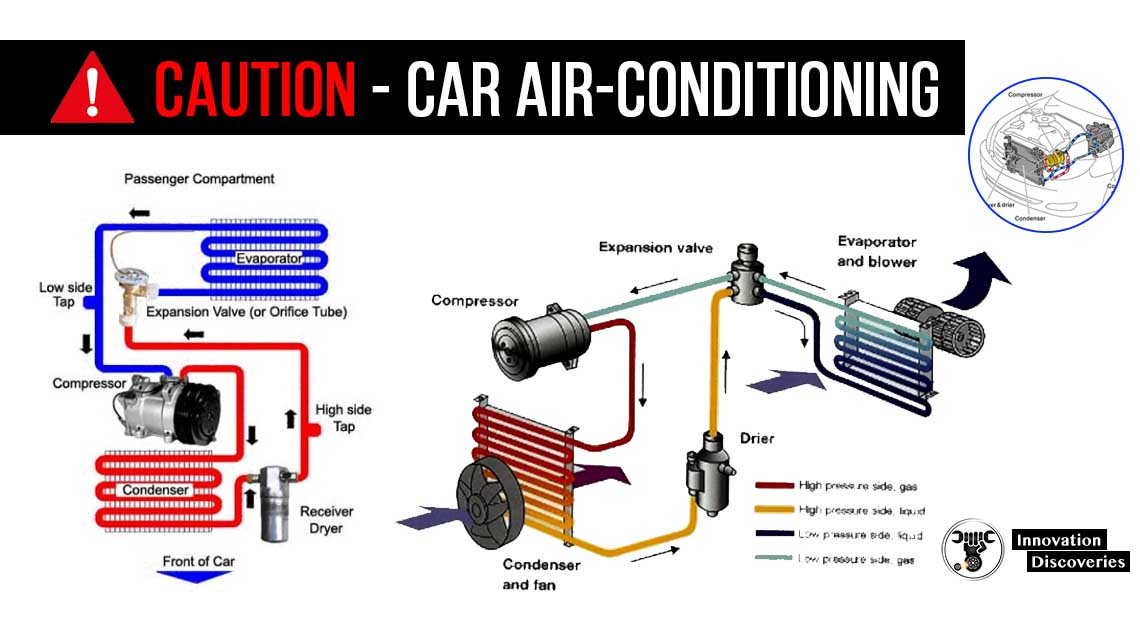

An air conditioning (AC) system is a crucial component in any vehicle, providing comfort during scorching summers. However, like all mechanical systems, AC systems are prone to failures, and one of the most common issues is a compressor failure. When a compressor fails, it can contaminate the entire AC system with debris, contaminants, and residual oil, potentially leading to more significant problems down the line.

To avoid further damage and ensure a successful repair, it is essential to flush the AC system after a compressor failure.

In this article, we will guide you through the steps of properly flushing your AC system to restore it to peak performance.

Safety FirstBefore we dive into the steps, it’s important to note that AC system repairs and flushing require specialized knowledge and tools. If you are not a qualified automotive technician, it’s best to leave this task to the professionals to ensure safety and a successful repair.

Step-by-Step Guide to Flushing Your AC System1. Recover Refrigerant:

The first step in flushing your AC system after a compressor failure is to recover any remaining refrigerant safely. The refrigerant must be properly recovered and recycled according to environmental regulations. This process requires specialized equipment and certification, so it’s best left to trained professionals.

2. Remove the Failed Compressor:

After the refrigerant has been safely recovered, remove the faulty compressor from the AC system. Inspect the compressor for any signs of damage or internal failure, as this can help identify the root cause of the problem.

3. Drain Residual Oil:

Allow any remaining oil in the system to drain out of the old compressor and other components. Measure the drained oil to determine the total oil capacity of the system, as you’ll need to add the correct amount of fresh oil later.

4. Attach the Flushing Kit:

To begin the flushing process, connect the AC system flush kit to the low-pressure side of the system. Follow the manufacturer’s instructions for proper connections.

5. Flush the System:

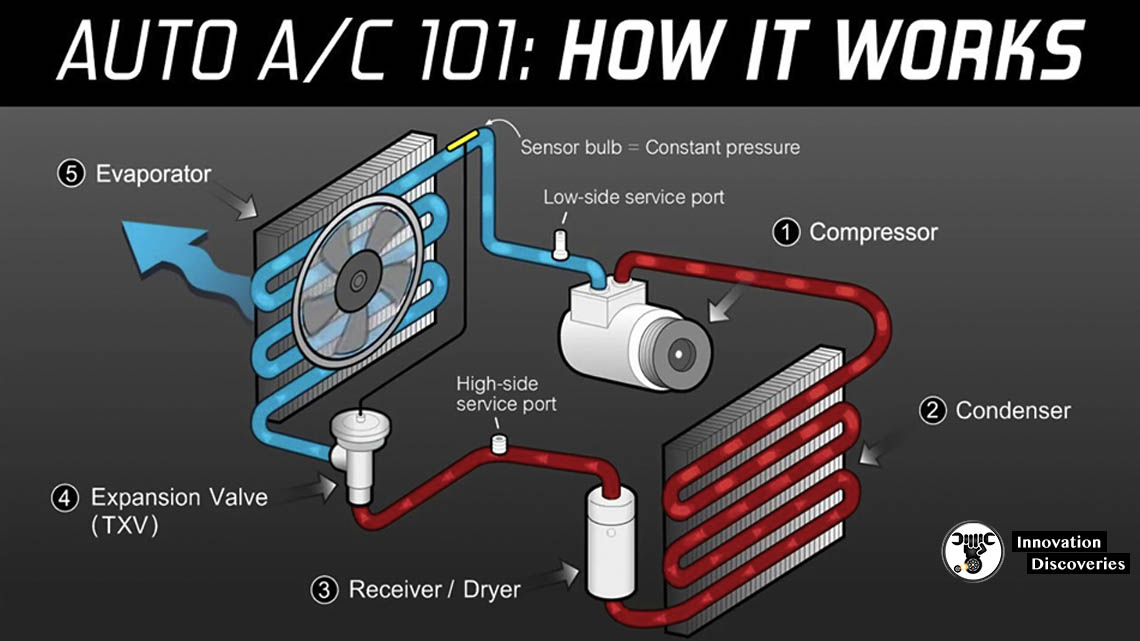

Introduce the AC flushing solvent into the system through the flushing kit. The flushing solvent is specifically designed to dislodge and carry away contaminants, debris, and residual oil. As the solvent circulates through the AC system, it cleans the lines, evaporator, condenser, and other components.

6. Flush Each Component Separately:

To ensure a thorough cleaning, flush each component of the AC system separately. This includes the evaporator, condenser, hoses, and any other parts that can be flushed. Refer to the flushing solvent manufacturer’s instructions regarding the duration and process for each component.

7. Drain the Flushing Solvent:

After flushing, disconnect the flushing kit and allow the flushing solvent to drain completely from the system.

8. Dry the System:

To remove any remaining flushing solvent and moisture, use compressed air to blow air through the AC system components.

9. Replace Components:

Install a new receiver/drier or accumulator, as well as a new expansion valve or orifice tube. These components should always be replaced after a compressor failure and system flushing.

10. Vacuum the System:

Once all components are in place, evacuate the AC system using a vacuum pump. This step is crucial to removing any remaining air and moisture from the system, preparing it for recharging.

11. Recharge the System:

Finally, recharge the AC system with the correct amount of refrigerant and oil specified by the vehicle’s manufacturer. Follow the recommended procedures for recharging the system.

ConclusionFlushing your AC system after a compressor failure is a critical step in ensuring the proper functioning and longevity of the new compressor and the entire AC system. Properly removing contaminants, debris, and residual oil will prevent future problems and optimize the performance of your AC system.

However, AC system repairs, including flushing, should only be performed by qualified automotive technicians. If you experience a compressor failure, seek the assistance of a professional mechanic or AC technician to ensure safety and a successful repair.

Discover more:

Read More:

- How Does A Turbofan Engine Work?

- 5 Causes of an Alternator Not Charging

Visit Forum

Visit Our Friendly Website

Tag » How To Flush Ac System

-

How To Flush Car AC System & Why It's Important | Sun Devil Auto

-

How To Flush Your Car's AC System - AutoZone

-

How To Flush Auto A/C Systems - YouTube

-

AC System Flush- AutoZone Car Care - YouTube

-

Flushing The Car AC System - Instructions | BEHR HELLA

-

How To Flush AC System After Compressor Failure? - Car From Japan

-

How Do You Flush Out An Auto AC System?

-

How To Flush An AC System

-

How To Flush Your Car AC System & Why It's So Important - Cox Auto

-

How To Flush AC System With Alcohol - MachineLounge

-

How To Flush The A/C System - It Still Runs

-

[PDF] Flushing And Cleaning The A/C System - PDF4PRO

-

Compressor Failure? Flush That System! - FJC Inc

-

Why Flush An AC System? - Highgate Air