ICE Vehicles Vs. Electric Vehicles - Elasto Proxy

Maybe your like

- Post author:Steve Melito

- Post published:12 March 2022

- Post category:Electric Vehicles / News

- Post comments:0 Comments

ICE vehicles ignite and combust fuel within an internal combustion engine (ICE). Electric vehicles (EVs) are powered by the electricity from a rechargeable battery instead. These are well-known and important differences, but did you know that ICE vehicles and EVs also share many components in common? For example, they both have gears and electric motors, use transmission fluid and coolants, and have braking and safety systems. Designers of ICE and electric vehicles are also adding an increasing amount of electronic content that can cause electromagnetic interference (EMI).

ICE Vehicles and the Electrification of Everything

For engineers in the heavy equipment and transportation industries, the electrification of everything can present challenges both old and new. For example, designers of diesel-powered equipment have long wanted to reduce the amount of engine noise that reaches the cabin. Electric vehicles eliminate engine noise because they use a battery, but EVs still need acoustic insulation because road noise now seems more pronounced. Regardless of a vehicle’s powerplant, problems such as buzz, squeak and rattle (BSR) from a faulty door or window seal also remain unwelcome.

Elasto Proxy understands the challenges that vehicle designers face and provides custom solutions to original equipment manufacturers (OEMs) in the heavy equipment and transportation industries. We also work with electric car companies that need industrial rubber products for applications ranging from EV battery boxes to charging stations. The main difference between ICE vehicles and EVs is about what generates the power for movement, but there’s so much more to consider. The table below and the sections that follow provide a comparison.

Table 1: ICE Vehicles vs. EVs

Internal Combustion Engine (ICE) Vehicle | Electric Vehicle (EV) |

High specific energy fuel | Low specify energy of battery |

Emits greenhouse gases | No tailpipe emissions |

Travels >600km / fill | Travels <250km / charge |

Short refilling time (<5 min.) | Long charging time (0.5 to 8 hrs.) |

Fuel tank takes relatively little space | Battery takes large space |

Fuel weight is low | Batteries are very heavy |

Higher maintenance cost | Lower maintenance cost |

Braking energy is not recovered | Can recover braking energy |

Running cost: high | Running cost: low |

Energy efficiency: 30% | Motor efficiency: 80% |

Needs complex gear system | Needs only one gear |

Noisy operation | Quiet operation |

Ample refilling infrastructure | Lacks charging infrastructure |

Need to pick up speed to deliver maximum torque | Produces maximum torque |

Uses only hydrocarbons | Uses electricity from many sources |

Electric Motors and EMI Shielding

ICE vehicles and electric vehicles both use electric motors, devices that supply motive power to either the vehicle itself or to another system. EV motors are larger than ICE motors, but both of these motors have two parts: a rotor that turns, and a stator that does not. In ICE vehicles, the stator touches the rotor through brushes and a commutator. A chemical reaction in the battery generates direct current (DC), which produces a magnetic field and spins the rotor. This rotation is transferred to the engine until the first ignition. Once the engine is started, rotation is transferred into motion.

In EVs, the stator does not touch the rotor. A chemical reaction in the battery generates DC current, but this DC is converted into alternating current (AC). In turn, the AC creates a magnetic field that causes the rotor to spin and transfers this rotation into movement. In both ICE and electric vehicles, there are electromagnetic fields between the rotor and stator. ICE vehicles generate these fields for just a short period of time, but EVs generate fields that are stronger and last longer. Consequently, EV designers need EMI gaskets to seal and insulate housings and enclosures for sensitive electronics.

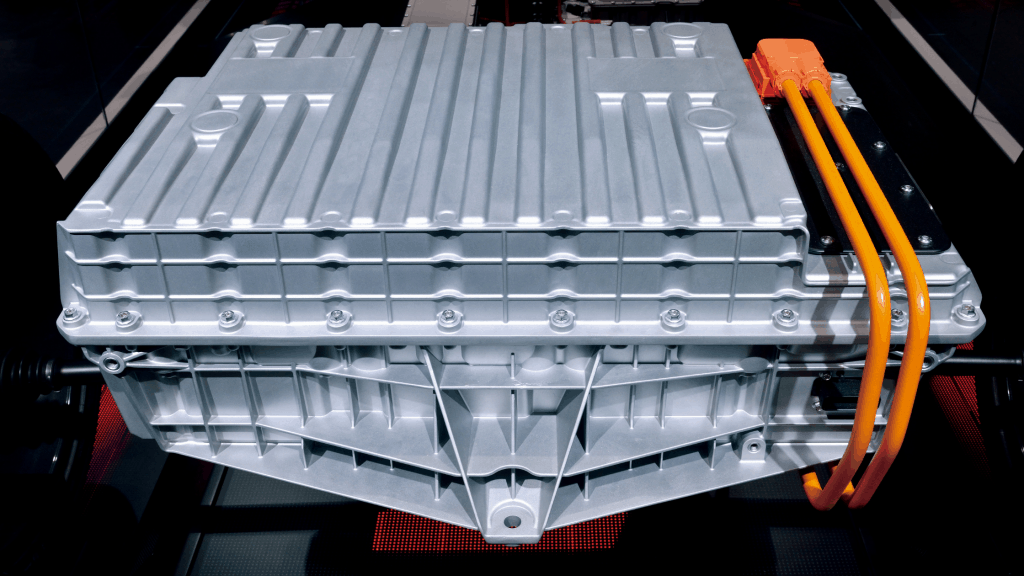

Chemical Energy and Energy Density

ICE vehicles and EVs both convert chemical energy into motion. For the internal combustion engine, this chemical energy comes from a fuel like gasoline or diesel. With EVs, the chemical energy comes from a rechargeable battery. Because gasoline and diesel are relatively lightweight but produce a high amount of power, they have high energy density. By contrast, EV batteries are heavy (500 kg) and have a low energy output. Consequently, EV power sources have a relatively low energy density – a potential problem with heavy trucks, trains, or buses that need significant energy to move a load.

Electric vehicles use a lower-density energy source, but EVs also use lighter weight components. For example, in many diesel-powered heavy trucks, door seals are made of EPDM rubber, an economical and weather resistant elastomers. Thermoplastic vulcanizate (TPVs) elastomers weigh significantly less than thermoset EPDMs and are finding applications in electric vehicles. High-performance TPVs with high heat resistant and excellent oil resistance are also used in under-the-hood ICE applications.

Efficiency, Torque and Weight

There are also differences between ICE vehicles and EVs in terms of efficiency. ICE vehicles convert the reciprocating, or up-and-down, movement of pistons into rotary motion. This conversion causes a major loss of efficiency and produces significant friction and vibration. Electric vehicles don’t need to convert reciprocating motion into rotary motion because the EV’s electric motor is already spinning. This leads to a 50% gain in efficiency (30% for ICE vs. 80% for EV) with only minimal friction and vibration. There are also differences in torque, a measure of the force that causes an object to rotate on an axis.

Vehicles with internal combustion engines have multiple gears, including for low and high speeds, to meet revolutions per minute (RPM) requirements for torque. The speed of rotation is controlled by the throttle, and the RPM range for optimal torque is between 2000 and 8000. By contrast, electric vehicles have only one gear and support a wider range of RPM. The speed of rotation is controlled by the frequency of the AC current, and the range for optimal torque is between 0 and 20,000 RPM. With their heavy batteries, however, the weight of a typical EV (610 kg) exceeds that of an ICE vehicle (240 to 480 kg).

Environmental Sealing and Thermal Insulation

Both ICE and electric vehicles need industrial rubber that can provide strong environmental resistance. Rain, snow, dirt, rust, road salt, and other contaminants from outside the vehicle need to be sealed-out and automotive fluids need to be sealed-in and kept clean. Compared to ICE vehicles, EVs store less liquid. There’s no fuel tank, of course, but EVs also need less transmission fluid. During the seal design process, however, it’s important to consider if an EV will be exposed to different types of chemicals.

Finally, vehicle designers need to keep in mind that EV battery packs must be kept cool during recharging. If one of the batteries in a pack overheats, the potential thermal runaway may ignite the other batteries in the pack. These battery packs are also sensitive to puncture and, once pierced, can leak electrolytes. Punctured batteries may also overheat when charging. High heat is also a problem with 5G electronics, which have higher densities and are expected to further revolutionize the transportation industry.

Do you need seals, gaskets, or insulation for internal combustion engine (ICE) or electric vehicles (EVs) that are used in the transportation or heavy equipment industries? Talk to Elasto Proxy and tell us what you need.

Contact Us Tags: electric vehicles, EV, ICE vehicles, internal combustion engine, Top 10 Blogs of 2022Read more articles

Previous PostElasto Proxy’s EV Roundup (February 2022) Next PostEMI Aerospace GasketsYou Might Also Like

Plastic Bags and the Environment: It’s Not That Simple

7 October 2013Sealing Success: Elasto Proxy Turns 25

2 June 2014

Have Fun at Work Day

29 January 2020Leave a Reply Cancel reply

CommentEnter your name or username to commentEnter your email address to commentEnter your website URL (optional)Save my name, email, and website in this browser for the next time I comment.

Sign Up for our Newsletter

Subscribe to our NewsletterRecent Posts

-

UAV Parts from Elasto Proxy6 February 2026/0 Comments

UAV Parts from Elasto Proxy6 February 2026/0 Comments -

Nuclear Glovebox Gaskets from Elasto Proxy2 February 2026/0 Comments

Nuclear Glovebox Gaskets from Elasto Proxy2 February 2026/0 Comments -

Naval Ships Need Elasto Proxy24 January 2026/0 Comments

Naval Ships Need Elasto Proxy24 January 2026/0 Comments

Categories

- Added Value Services (14)

- Aerospace (22)

- Bulb Trim Seals (20)

- Bumpers (4)

- C-Suite (63)

- Customer Support (14)

- Dual Durometer Rubber (1)

- Edge Trim (12)

- Elasto Life (21)

- Electric Vehicles (25)

- EMI RFI (15)

- Engineered Rubber Products (233)

- Engineering (371)

- Events (27)

- Food Equipment (23)

- Heavy Equipment (374)

- Industrial Tubing (2)

- Industry (7)

- Insulation (48)

- Marketing (17)

- Medical (20)

- Military (65)

- Molded Parts (11)

- News (199)

- Operations (74)

- Other (17)

- Purchasing (76)

- Quality Control (10)

- Rubber Floor Matting (6)

- Rubber Sheeting (2)

- Sales (17)

- Sealing the Win with True Costs (8)

- Shipping & Logistics (11)

- Solid Profiles (2)

- Sponge Profiles (3)

- Standard Rubber Products (49)

- Videos (17)

- Weather Stripping (4)

- Window Channels (7)

Archives

Archives Select Month February 2026 January 2026 December 2025 November 2025 October 2025 September 2025 August 2025 July 2025 June 2025 May 2025 April 2025 March 2025 February 2025 January 2025 December 2024 October 2024 September 2024 August 2024 July 2024 June 2024 May 2024 April 2024 March 2024 February 2024 January 2024 December 2023 November 2023 October 2023 September 2023 August 2023 July 2023 June 2023 May 2023 April 2023 March 2023 February 2023 January 2023 December 2022 November 2022 October 2022 September 2022 August 2022 July 2022 June 2022 May 2022 April 2022 March 2022 February 2022 January 2022 December 2021 November 2021 October 2021 September 2021 August 2021 July 2021 June 2021 May 2021 April 2021 March 2021 February 2021 January 2021 December 2020 November 2020 October 2020 September 2020 August 2020 July 2020 June 2020 May 2020 April 2020 March 2020 February 2020 January 2020 December 2019 November 2019 October 2019 September 2019 August 2019 July 2019 June 2019 May 2019 April 2019 March 2019 February 2019 January 2019 December 2018 November 2018 October 2018 September 2018 August 2018 July 2018 June 2018 May 2018 April 2018 March 2018 February 2018 January 2018 December 2017 November 2017 October 2017 September 2017 August 2017 July 2017 June 2017 May 2017 April 2017 March 2017 February 2017 January 2017 November 2016 October 2016 September 2016 August 2016 July 2016 June 2016 May 2016 April 2016 March 2016 February 2016 January 2016 December 2015 November 2015 October 2015 September 2015 August 2015 July 2015 June 2015 May 2015 April 2015 March 2015 February 2015 January 2015 December 2014 November 2014 October 2014 September 2014 August 2014 July 2014 June 2014 May 2014 April 2014 March 2014 February 2014 January 2014 December 2013 November 2013 October 2013 September 2013 August 2013 July 2013 June 2013 May 2013 April 2013 March 2013 February 2013 January 2013 December 2012 November 2012 October 2012 September 2012 January 2011Request A Quote

Fill in your details and we’ll get back to you.

Request a quote for [elastoproxy-product-name][elastoproxy-product-images]

What is Notching ?

Notching removes just the right amount of material for features like raised fastener heads.

Notching removes just the right amount of material for features like raised fastener heads. |

What is Splicing ?

Splicing bonds or joins the ends of rubber profiles to create finished gaskets.

Splicing bonds or joins the ends of rubber profiles to create finished gaskets. |

What is Cut Lengths ?

Cut lengths meet RMA tolerances and are water jet cut from coils of rubber.

Cut lengths meet RMA tolerances and are water jet cut from coils of rubber. |

What is Kitting ?

Puts everything your intallers need into a single box to save time on your assembly line.

Puts everything your intallers need into a single box to save time on your assembly line. |

What is UV Printing ?

UV printing marks parts with letters and numbers and promotes traceability.

UV printing marks parts with letters and numbers and promotes traceability. Tag » What Is An Ice Car

-

ICE Vehicle Definition | Law Insider

-

What's An EV? What's An ICE? What's A C-Segment Car?

-

EV Vs ICE: Are Electric Cars Worth It? - Mer UK

-

ICE, HEV, PHEV And BEV – What They Mean And What's Under The ...

-

What Does "ICE" Mean When Referring To Electric Cars? - Jerry

-

EV, PHEV, ICE – What Does It Mean? Electric Vehicle Dictionary

-

Ice Car Definition & Meaning - Merriam-Webster

-

EV Vs ICE - Differences And Similarities - ArenaEV News

-

Internal Combustion Engine (ICE) VS Electric Cars - Carro

-

BEV, PHEV, HEV, ICE - Electric Car Home

-

How Much Can You Save By Trading In An ICE Vehicle For An ...

-

EV Vs. ICE: How Far Can You Travel In Each State For $100? | Electrek

-

EVs And ICE Vehicles Will Need To Share The Road For A Long Time

UAV Parts from Elasto Proxy6 February 2026

UAV Parts from Elasto Proxy6 February 2026 Nuclear Glovebox Gaskets from Elasto Proxy2 February 2026

Nuclear Glovebox Gaskets from Elasto Proxy2 February 2026 Naval Ships Need Elasto Proxy24 January 2026

Naval Ships Need Elasto Proxy24 January 2026