Stripped Thread Repair - Applied Maintenance Specialties

Maybe your like

- Orders

- MetalinkWear.com

- LoneStarChemical.com

- Employment

- Contact Us

- Knowledge Base

- Bearing, Bushing, and Seal Fits Repair

- Centrifugal Pump Coating

- Chutes and Exhauster Fan Repair

- Cobbles prevention slippage reduction

- Cooling Tower Distribution Pipe Repair

- Cracked Engine Block Repair

- Flange Repair

- Flat Back Elbow Repair

- Heat Exchanger Repair and Coating

- Keyway Repair

- MSDS

- Pipe and Leak Repair

- Process Cyclone Repair

- Pump Housing Crack Repair

- Pump Impeller Repair

- Pump Volute Repair

- River Discharge Pump Maintenance

- Scored Hydraulic Ram Repair

- Shaft Repair

- Spline Shaft Repair

- Split Case Housing Repair

- Stripped Thread Repair

- Surface Preparation for Polymer Application

- TSA Surface Preparation and Application

- Tube Sheet Repair

- Valve Seat Repair

- What is TSA?

- MSDS

- Menu

- Specialty Products

- Thermal Spray Wire

- Maintenance Chemicals

- Lease Equipment

My Account My Account

- Orders

Stripped out bolt holes can be repaired easily using Machinable Repair™ or Fas-Steel 4™ (depending on strength requirements.See technical data).

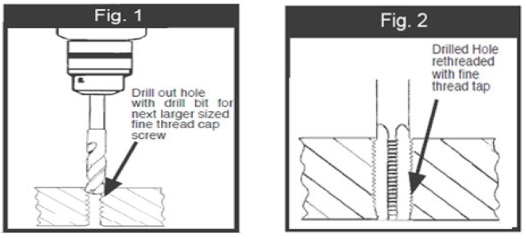

1)Drill out the stripped thread hole using the appropriate drill bit for the next larger sized fine thread cap screw (e.g., 3/8-16 stripped threads, use a 25/64 drill, which is the designated drill for 7/16-20 threads). (Fig. 1)

2)Rethread the hole completely using the corresponding fine thread tap. (Fig. 2)

3)Degrease the hole surrounding surfaces with Metal Prep II™. Also degrease an original sized cap screw.

4)Mix up the Metalink repair compound according to instructions on containers.

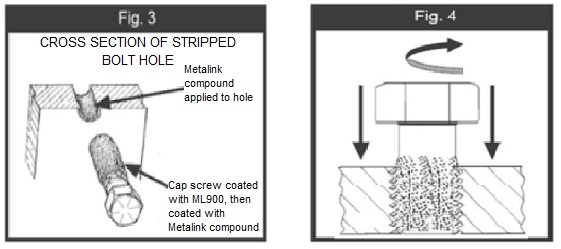

5)Using a small, flat blade object, coat the inside of the bolt hole, making sure to spread the compound around evenly, forcing it into the threads. (Fig.3) (Note: If using Fas-Steel 4 in the Shur-Shot syringe, you can apply the compound directly into the hole, but will still need to force compound into the threads.)

6)Coat the cap screw with Silicone Lubricant & Release Agent. Now apply a thin layer of Metalink repair compound completely around the thread area, assuring it is forced into the threads just as in the hole. (Fig. 3)

7)Push the cap screw down into the hole. Twist the cap screw once to integrate the Metalink compound applied to the cap screw with that pressed into the thread walls. (Fig. 4)

8)Allow the Metalink compound to completely set before moving or removing excess compound. (See technical data)

- Sign in

- Create account

- Contact Us

- Gift certificates

- Sitemap

Customer Service

- About your order

- Wishlist

- Compare list

- Subscriptions

- Credit Application

Find us on Facebook Follow us on Twitter

Stay Connected

EmailTag » How To Rethread A Bolt Hole

-

Repair Damaged Nuts And Bolts (DIY) - The Family Handyman

-

How To Rethread A Hole Using A Tap And Die Set - YouTube

-

How To Fix Stripped Bolt Hole Threads On Your Car - YouTube

-

How To Rethread A Stripped Bolt Hole Video - YouTube

-

FIX Stripped Bolt Hole Threads The POOR MANS WAY - YouTube

-

How To Repair Stripped Bolt Hole Threads - AxleAddict

-

How To Fix Stripped Bolt Holes - AutoZone

-

How Do You Fix A Stripped Bolt Hole In An Engine Block? - Jerry

-

Three Ways To Fix A Damaged Thread | Insert Tech 101

-

What Are The Options For Repairing A Threaded Bolt Hole Without Drilling?

-

How To Fix Stripped Threads - NAPA Know How Blog

-

What Tool Is Used To Rethread Damaged Bolt Holes? - Quora

-

How To Fix A Cross Threaded Or Stripped Hole In Aluminum - IFixit

-

How To Re-thread The Bolt Hole? - Unofficial Honda FIT Forums