Understanding Duty Cycle For Welding Machines

Maybe your like

One of the specs we need to know about a particular welding machine is its duty cycle. The duty cycle gives you an idea of how hard and how long you can run a welding machine before it overheats and shuts down. Unfortunately at times we have issues with machines exceeding the duty cycle when it shouldn’t, or when we think it shouldn’t.

Although once in a great while a machine can have a faulty thermostat the main issue for a thermal overload is in fact that the duty cycle was exceeded. Frustration sets in mainly because there is no detailed explanation about duty cycle. We typically hear: “This welder has a 30% duty cycle at 150amps.” And although this may be correct it leaves out pertinent information such as welding voltage, ambient temperature, and proper ventilation.

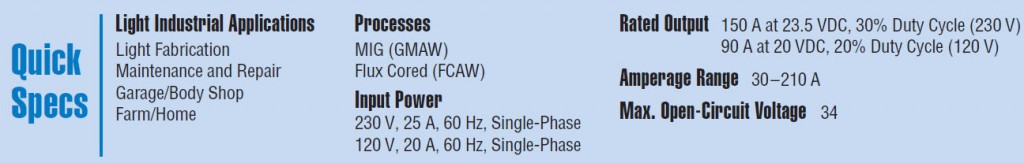

Let’s take a quick look at the Millermatic 211:

Duty Cycle is the number of minutes out of a 10-minute period a welder can operate continuosly.

According the spec sheet for the Millermatic 211 as published on Miller Electric’s site this machine has a duty cycle of 30% at a rated output of 150A on 230VAC input power. Most manufacturers do this. They have a machine that can weld, as is the case with this one, up to 210 amps. The name also suggests it (211), yet the rated output for duty cycle purposes is 150 amps. If one hears that this machine has a duty cycle of 30% they may assume 30% at full output. They would quickly find out that at 210 amps the duty cycle is much lower.

Per the definition of duty cycle stated above the Millermatic could weld continuosly, at 150 amps, for 3 minutes and must then rest for 7 minutes. Duty cycles published are sometimes conservative and you may be able to push this a bit and get a few more minutes of welding.

So why is your welder cutting out before those 3 minutes if you are welding at 150 amps?

There are three factors that contribute to this:

Voltage – What is usually not considered is welding voltage. The state duty cycle of 30% is at 150 amps is at 23.5 volts. However, if the we crank up the voltage to 25 volts then the duty cycle at 150 amps would be lower. This can cause the unit to shut down after only 2 minutes.

Ambient Temperature – This is rarely shown on any spec sheet by any manufacturer. Most duty cycles are based on an ambient temperature of 70F. If the temperature in the shop is 100F and you are welding at 150 amps and 23.5 volts you may have a duty cycle that is much lower than the 30%. Remember, the machine is running a fan to stay cool, but the hotter the air is in the shop the lower the cooling effect it has on the internal components.

Ventilation – If the machine is backed up against a wall this decreases the airflow generated by the fan. Allow at least 10-12 inches of space between the unit and the wall. Without proper airflow the machine doesn’t cool as efficiently and this results in a lower duty cycle.

One last thing, for machines such as this one that can run multiple input voltages keep in mind the duty cycle is derrated the lower the input voltage. The machine above only has a 20% duty cycle running 90 amps on 110VAC.

Tag » What Is Duty Cycle In Welding

-

What Typical Duty Cycles Are Achieved When Arc Welding? - TWI Global

-

Welding Machines - What Is Duty Cycle & How Is It Calculated?

-

What Is Duty Cycle In Welding And How Is It Calculated?

-

What Is Duty Cycle In Welding? (with Chart) - Weld Guru

-

What Does Duty Cycle On A Welding Machine, Mean?

-

What Is Duty Cycle In Welding?

-

What Is Duty Cycle? - Welding Thematic Explained By CEAWELD

-

Explanatory Video On What Is The Duty Cycle In Welding? - Dynaweld

-

What “Duty Cycle” Means For Welding Machines - Make It From Metal

-

Does Duty Cycle Really Matter? - Welding Supplies From IOC

-

What Is A TIG Welding Duty Cycle And Why Does It Matter?

-

Duty Cycle In Welding: Decoded With Example Calculation

-

Duty Cycle In Welding | Weldknowledge

-

Duty Cycle For Dummies | MIG Monday - YouTube