Vacuum Forming: Types, Uses, Features And Benefits - IQS Directory

Maybe your like

Contact Companies

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

CloseGet Your Company Listed on this Power Page

Introduction

This article will give an in depth understanding of vacuum forming.

You will be able to learn about:

- What is vacuum forming?

- Materials used in vacuum forming

- Machines used in vacuum forming

- Types of products made from vacuum forming

- Pros and cons of vacuum forming

- And so much more…

Chapter 1: What Is Vacuum Forming?

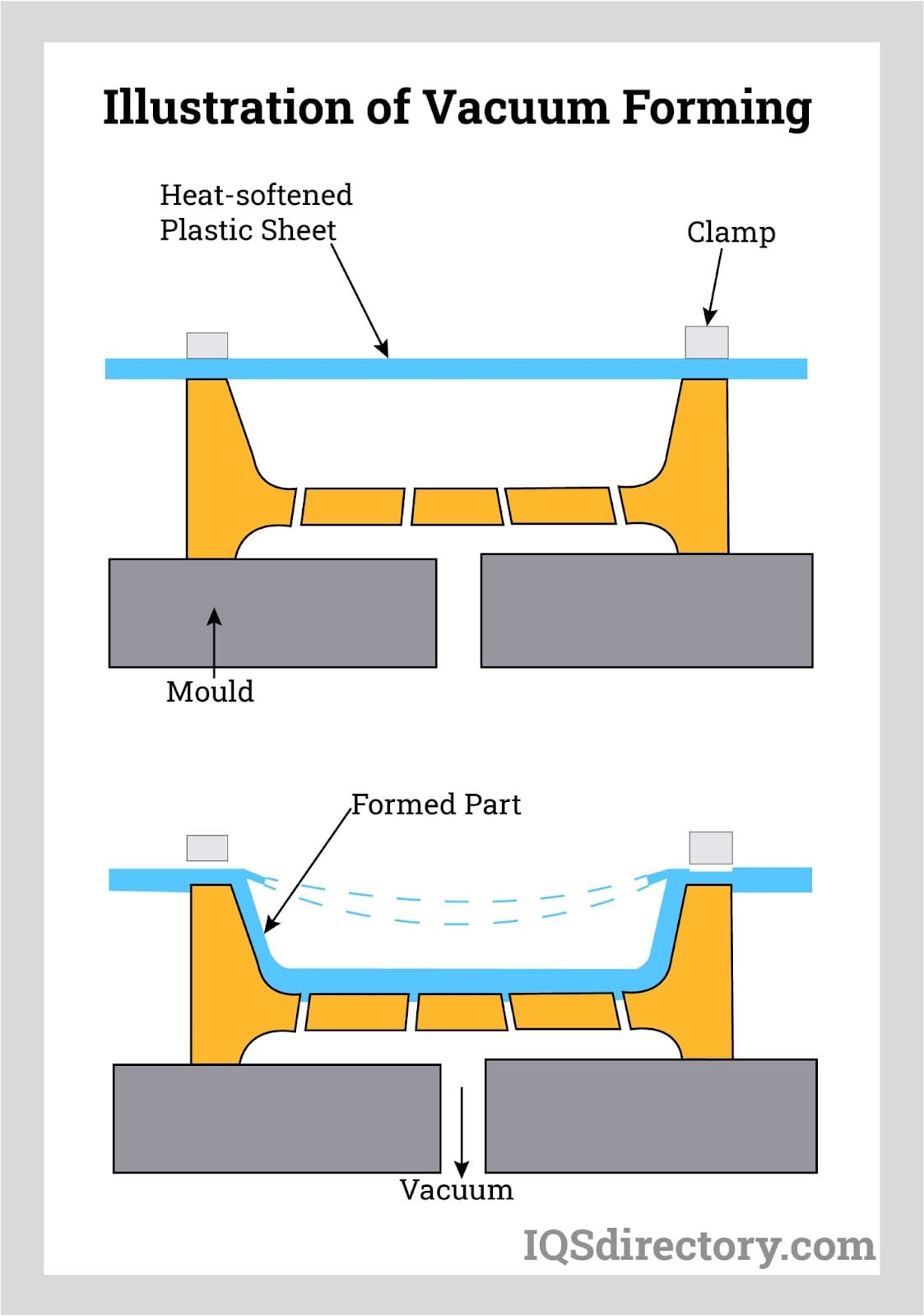

The process of heating and shaping the plastic material using a vacuum is called vacuum forming.

Vacuum forming is one of the oldest and cheapest methods for plastic molding and is widely used in our everyday life, from smaller objects to huge industrial machinery. The vacuum forming process is being used at a large scale due to its low cost, efficiency, speed of imitation, and ease of use for shaping smaller objects molds. Vacuum forming is a process in which a layer of plastic is placed on the mold, and then a suction force is applied to shape the plastic according to the desired shape. Vacuum forming is also known as the simplest form of plastic thermoforming as only a mold is required, and the plastic is placed over it.

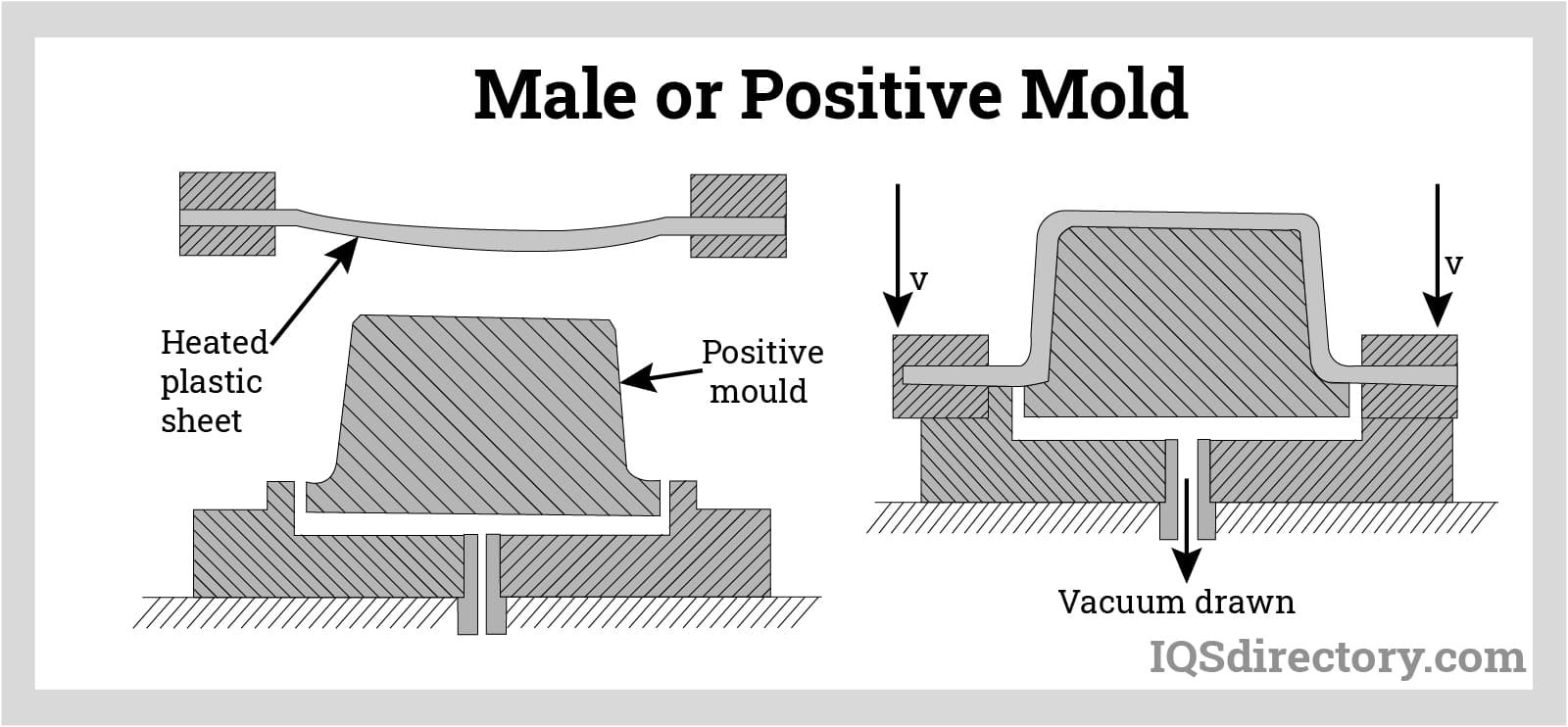

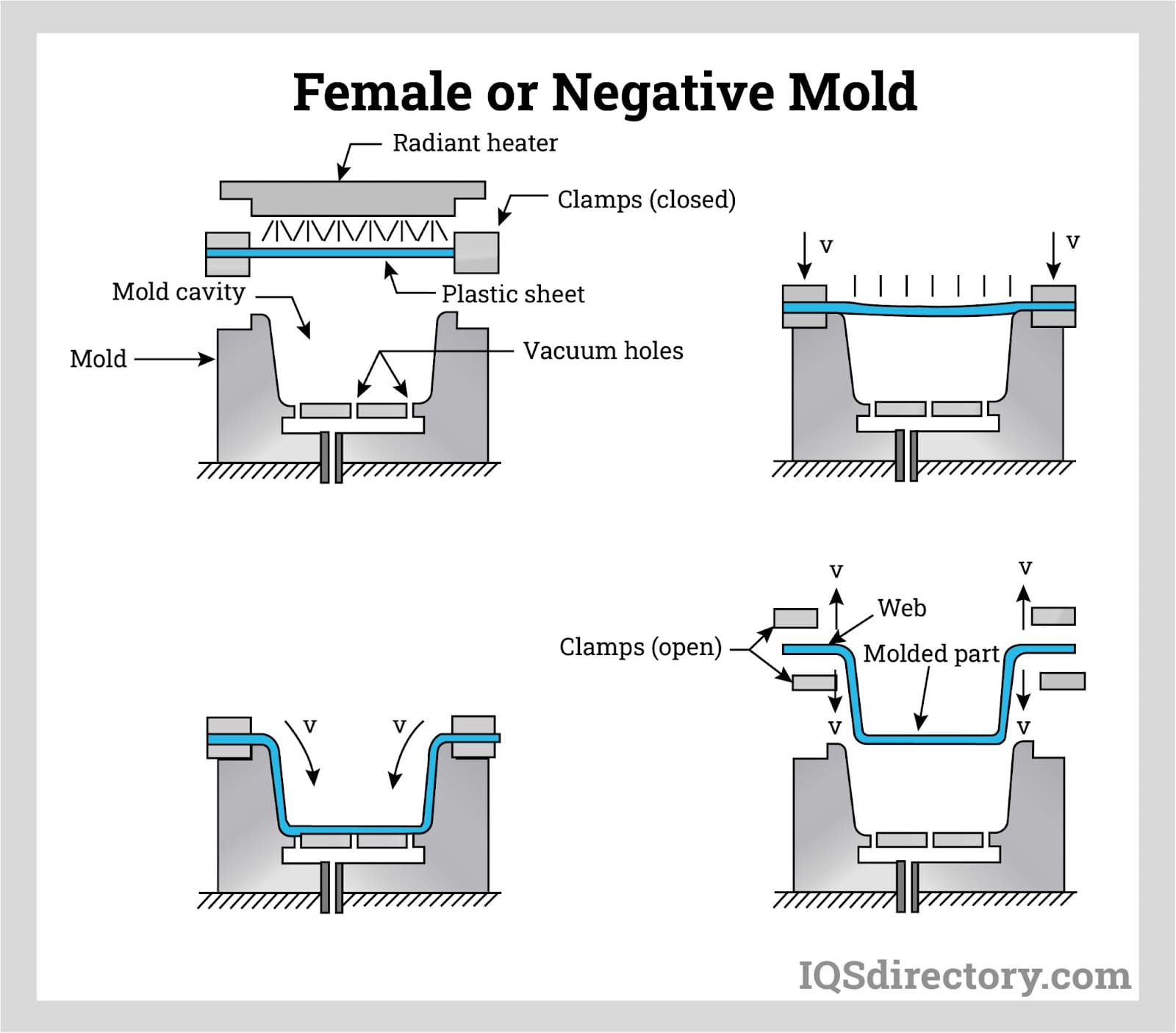

There are two types of molds that are used in vacuum forming that are:

- Male or positive mold

- Female or negative mold

The male or positive mold is a convex-shaped one. The plastic is placed on the outside layer of the mold, which helps contour the inner dimensions of the plastic, while the female or negative mold is concave shaped. The plastic is placed inside the mold to contour the outside dimensions of the plastic accurately.

Vacuum forming, as discussed earlier, is the simplest of all forms. Still, now advanced technology is being introduced, such as heat, hydraulic and pneumatic controls to produce more precise and desired products at a reasonable production speed. Many products are made from vacuum forming, such as bath and shower trays, vehicle parts, refrigerator liners, plastic storage boxes, etc.

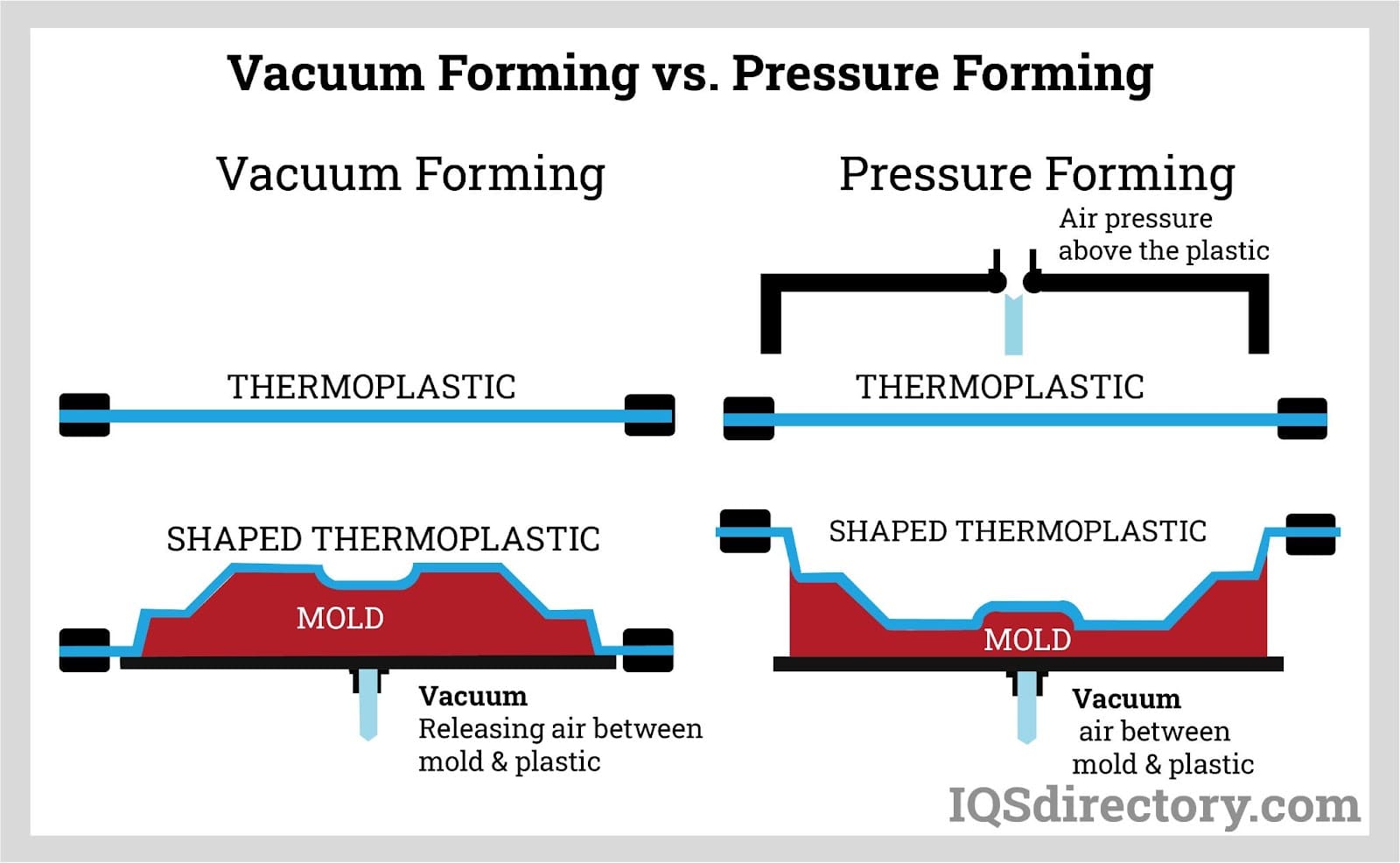

Difference between Thermoforming, Vacuum Forming and Pressure Forming

A process of heating a plastic sheet to make it flexible and then contouring in desired molds, trimming the final product is called thermoforming. Thermoforming is then categorized into two types:

- Vacuum forming

- Pressure forming

The main difference in these is the number of molds used in their product manufacturing.

Vacuum forming is done using a single mold and a vacuum pump. The heated sheet is placed into the mold, and a vacuum is applied to place it properly into the mold of the desired shape. It is mainly used in the contoured packaging of food and electronics etc. At the same time, pressure forming is done with the help of two molds. The sheet is placed within one mold and then pressed by placing the other mold on it rather than using suction from the vacuum pump. This process enables precise and aesthetically good-looking molds such as appliances casing etc. Furthermore, pressure forming is very suitable for manufacturing the plastic parts that are needed to be shaped evenly and that go deeper into a mold.

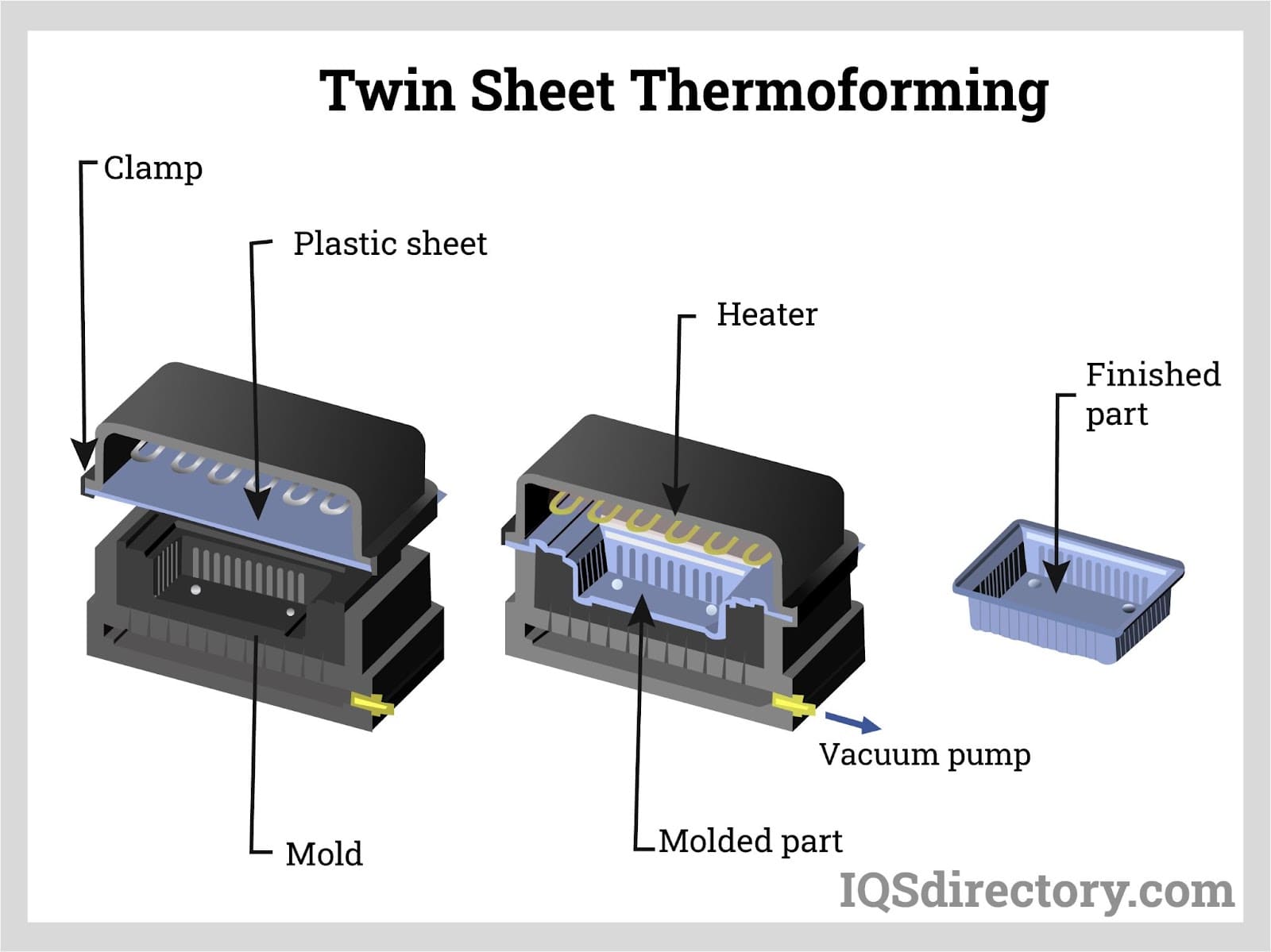

Twin Sheet Thermoforming

Twin sheet thermoforming is a process in thermoforming that is done either by pressure forming or vacuum forming but with the help of two molds. It is a compression process that creates two plastic sheets simultaneously, one on the top platen and the other on the bottom platen. Once the sheets were formed, they remained in the vacuum at their melting temperature. Both the platens are compressed and joined together to form a single product. Twin sheet thermoforming is used for the products that are hollow in structure. The process of twin sheet thermoforming is shown in the figure below:

This process has advantages over other processes.

These are:

- Lower tooling costs about 20-30% less than other processes.

- It is allowed for an enclosed cavity.

- The products made from twin sheet thermoforming are more rigid and stable than thin-walled thermoforming.

- This process can include internal reinforcements.

Twin sheet thermoforming is used to make pallets, portable toilets, toys, fuel tanks, marine products, doors, ventilation ducts, surfboards, spine boards, and many other transportation products.

Materials Used In Vacuum Forming

Vacuum forming can be done on a variety of thermoplastics, but typically the materials that are used in vacuum forming are as follows:

Materials Used In Vacuum Forming

Vacuum forming can be done on a variety of thermoplastics but typically the materials that are used in vacuum forming are as follows:

Polycarbonate (PC)

Polycarbonate (PC) is a plastic polymer used to make many machine parts. It is a good choice as it is virtually unbreakable, highly resistant, UV protected from one or both sides, half the weight of glass, and hence they are easy to install and handle in the machine. It is used in light diffusers, skylights, aircraft trims, etc.

Polystyrene (PS)

Polystyrene (PS) is the most versatile thermoplastic available in many formulations. Polystyrene is moderately intense, precise, brittle, and rigid when unmodified. In addition, it has good electrical properties, dimensional stability, low cost, versatility, and is easy to process. As a result, it is widely used in food packaging, disposable cups, and plates.

Polypropylene (PP)

Polypropylene (PP) is also a polymer of plastic. It is used in the vacuum forming process as a material for certain objects such as model making, crafts, and report covers in schools and offices. These sheets are inflexible, semi-rigid, with high heat, fatigue, and chemical resistance. In addition, they are crystalline, non-polar, and translucent in appearance.

Polyvinyl Chloride (PVC)

Polyvinyl chloride is readily available and is used in high quantities.It is highly economical with excellent tensile strength, rigidity, and high density compared to all other plastic polymers. In addition, it is eco-friendly with high chemical resistance. It is mainly used for commercial purposes like digital and screen printing, laminations, vinyl lettering, etc.

Polyethylene (PE)

Polyethylene is a plastic sheet made from petroleum, and it is highly resistant to water and chemicals. Very stable in cryogenic environments, low coefficient of resistance, and highly malleable. It is widely used because of its low cost and is suitable for almost all environments.

Polyester Copolymer PETG

It is a thermosetting plastic in unmodified form with high durability, strength, and resistance to harsh environments. It is used in the vacuum forming technique because it can be easily molded, dye cut, and formed.

Acrylic PMMA

Acrylic PMMA is a widely used plastic sheet that is challenging, transparent, easy to mold, and more economical than high cost, less resilient glass. It is used in cars, windows, smartphone screens, and even aquariums.

Acrylonitrile Butadiene Styrene ABS

Acrylonitrile Butadiene Styrene ABS is a thermoplastic insoluble in water with excellent chemical, impact, abrasion, and stress resistance properties. It is rigid, hard, and a stable plastic with good electrical properties. It is used to make rigid pipes, automobile parts, car wheels, etc.

Tag » Where To Buy Vacuum Forming Plastic

-

Vacuum Forming Plastic

-

24"x48"x 1/16" ABS Plastic Vacuum Forming Sheet Textured Front ...

-

Vacuum-Forming Plastics - Professional Plastics - Sheets

-

China Vacuum Forming Plastic Sheets - Alibaba

-

Vacuum Forming - Singapore - Etsy

-

Plastics For Vacuum Forming | Röchling SG

-

Vacuum Forming Services - Emco Industrial Plastics

-

Plastic Vacuum Forming Machines For Sale - EBay

-

Vacuum Forming Sheet (HIPS) - Shop Online - Hindleys

-

Vacuum Forming | Eagle Plastics | Thermoplastic Sheet Supplier

-

Vacuum Forming Sheet Manufacturers & Suppliers

-

Plastics For Vacuum Forming | Stephen Webster Plastics

-

Vacuum Forming Plastic: The Best Plastics, Method & Products