Where To Work When You Have No Shop - FineWoodworking

Maybe your like

Absolute beginner here in Southeast VA. This is my first post in this great community.

I have a small home with no room for a shop (no garage or basement) and have been looking for ways to get into woodwork, given my limitations. I have a few power tools (drill press, router and table, miter saw) but don’t really use them much on account of they don’t have a permanent home at my house.

I thought I could work in the shed out back but it turns out that it’s not moisture sealed. It’s actually just a walled off car port with a dirt floor that was built before I moved here. I brought home my new drill press and within the week, the table was showing rust. I cleaned it up and brought it inside, and cursed my misfortune.

I’d like to eventually build tables, but that’s a long way off. Im starting with small projects like tea boxes or gifts.

Help me out gals and guys!

XReplies

-

roy.unit8c | Nov 11, 2019 10:17am | #1

roy.unit8c | Nov 11, 2019 10:17am | #1 Have you looked for community workshops in your area? There is usually a monthly fee. Experienced woodworkers are usually available to give orientation classes before using machines or to give you pointers as you work. If there is no community workshop nearby, you could look for woodworking clubs and classes where access to workshop space may be available.

-

MikeInOhio | Nov 11, 2019 12:17pm | #2

MikeInOhio | Nov 11, 2019 12:17pm | #2 Don't be discouraged. Lots can be accomplished in a small space. Years ago, I did my woodworking on a second floor apartment balcony using a Workmate and hand-held power tools.

For inspiration, check out this YouTube video called: My 95 SQFT Apartment Workshop

https://www.youtube.com/watch?v=02CscUIE8FE&t=52s

It can be done!

Mike

-

chipsawdust | Nov 11, 2019 01:22pm | #3

chipsawdust | Nov 11, 2019 01:22pm | #3 Find a friend with a little extra space? It’s a pain to go there but for example, I have a friend with a lift in his shop so when I need to do something to my car or truck, I can drive out there and use it. Takes a good friend though :)

-

user-5277995 | Nov 11, 2019 02:16pm | #4

I managed to build a tool chest (C Schwartz Anarchist tool chest) on my living room table. I bought a sjoberg small vice, and was clamping it to the table and did my work there. Been using hand tools only, but i guess few power tools wont hurt !

-

joeleonetti | Nov 11, 2019 03:36pm | #5

joeleonetti | Nov 11, 2019 03:36pm | #5 I do hand tools as well. You can really work in small spaces.

-

bilyo | Nov 11, 2019 09:08pm | #6

bilyo | Nov 11, 2019 09:08pm | #6 What is the possibility of making improvements on the carport to make it a suitable workspace? If all it needs is being waterproofed, insulation, and a floor, that should be doable by the average woodworker.

-

sclause | Nov 12, 2019 01:04pm | #7

sclause | Nov 12, 2019 01:04pm | #7 I bought a 10' x 16' shed that they brought in on a trailer and set up on blocks. Not the cheapest but it gave me a starting point. I have been acquiring tools some used some new over the last two years. I now have a drill press, miter saw, table saw, bandsaw, router, jointer and planer. I have just run power after a year and a half of drop cord power. I now realize it is to small but to save the budget I am putting the miter saw & stand into storage to see how I adapt. It is a slow process so take one thing at a time to see what you can improve. I don't know if you can jack up the carport or trim the bottom of the walls and pour a concrete floor but that would really cut back on the moisture coming out of the earthen floor. You may even want to extend that pad outside for an outdoor space to work or expand later. I often move my table saw outside to make room or work longer boards & sheet goods.

-

user-6319763 | Nov 12, 2019 05:06pm | #8

user-6319763 | Nov 12, 2019 05:06pm | #8 Woah, I love all of the responses! You all are great! I knew I made the right move asking this awesome community.

There is a makerspace near me but my work hours prevent me from being able to go often enough while it's open to justify the monthly cost. Great idea, though!

The video linked is pretty amazing! I'm inspired by his custom solutions to space limitations and the dust management on his miter saw setup is pretty clever!

My sister has a decent sized garage I could use but my brother in law is using it for his roofing business - otherwise, that'd be a perfect solution! Maybe I can rent out a small corner for my tools...

I think I'm going to go the hand tool rout and work mostly on a small table in my 'dining room' (we eat our meals at a table in the den). I just need to build / buy a workbench that fits the space.

I've been considering how to improve the carport to fit my needs and I love the idea of pouring a concrete floor and then even adding a pad outside. I'm afraid the port is too old and poorly built to function long-term as a workshop. I'm concerned that it wouldn't last long enough to last the time / money I put into it.

I'm planning on building a detached 4 car garage with loft space for game nights and an electric car charging station. That project is a couple of years down the road. Half of the garage will be reserved for my workshop, so I'll have room to expand into, eventually.

These suggestions are all so great and I'm so grateful for the replies (and future responses I'm going to get). You guys and gals rock!

-

selwyn41 | Nov 12, 2019 07:20pm | #9

selwyn41 | Nov 12, 2019 07:20pm | #9 I remember seeing an article about a guy who lived in an apartment and had a closet with a window in it. I remember a picture of a piece of lumber sticking out the window. Another option is to get a tool chest on wheels (Craftsman sell several sizes) with a wood top on it. Maybe you can put it in a closet and wheel it out when you want.

-

user-6319763 | Nov 12, 2019 08:50pm | #10

user-6319763 | Nov 12, 2019 08:50pm | #10 I posted a response thanking you all for the awesome replies, and even got an email saying that I had posted it, but I don't see it on here. So, one more time, thank you all so much! I love all of the ideas. Some of them I can do, some of them I'm not able to. I think I'm going to start off with a custom built workbench in my house and work with hand tools. My carport is too old and I don't think it's structurally ready for a remodel. In a couple of years, I intend to build a 4 car garage with a loft. My and my wife's cars will go in half, my workshop in the other and our game night stuff up in the loft. Thanks so much for the awesome feedback, gals and guys! Keep it coming, I think this is a great discussion so far!

-

user-7543263 | Nov 13, 2019 04:07am | #11

Don't get discouraged and a lot can be accomplished within a small space.

-

jillygouse | Nov 13, 2019 02:19pm | #12

jillygouse | Nov 13, 2019 02:19pm | #12 Just one year ago I take a class for few days and than leave it. But now I'm so much interested in it and looking forward to learn how handled machine well.

-

chipsawdust | Nov 13, 2019 05:20pm | #13

chipsawdust | Nov 13, 2019 05:20pm | #13 You're making me feel like my 13' x 24' space is huge! :) I'm using the house-end of an attached, oversized two car garage. I hung plastic sheets between the shop and the cars in an effort to hold in a tiny bit of heat int he winters, and it also helps keep my tools hidden from the street when the garage door is open. All I can say beyond that is, hand tools notwithstanding, get lots of lighting and outlets!

-

fivebirdscustom | Nov 14, 2019 10:00am | #14

fivebirdscustom | Nov 14, 2019 10:00am | #14 My wife has been promising me that the next house we buy would have a shop... Since we got married (and I gave up my home with a shop). Because I have had no dedicated shop space, I've done mostly onsite work.

I was born and raised in Virginia, so I do know the struggle of rust and tools! Holy cow, do I know. But, I spent years taking tools in and out of the house to work outside in the driveway, or backyard. I bought a table saw with a rolling stand, used a small portable router table, never got a big bandsaw, used handheld power tools and made jigs, all of it. It was frustrating at times, but I made a living at it and, more importantly, continued my love of woodworking.

When we made our last move, my plan was to probably find a shop away form home. I'm getting too old and broken to keep working on jobsites. I also wanted to do more fine woodworking, build furniture and guitars again, start carving again, etc. However, I have lucked into a garage space that is now a dedicated shop. It's been a real pleasure... But, it was never truly a requirement. It's made it easier to do a lot of things, but I built a lotta stuff dragging stuff in and out of the house.

Good luck and enjoy the ride!

-

[email protected] | Nov 14, 2019 01:44pm | #15

[email protected] | Nov 14, 2019 01:44pm | #15 Here's an option that might not have been mentioned. When I was starting out, I enrolled in a local community college that had an excellent woodworking program and took basic entry level class one night a week. I had no intention to make it a career, but wanted access to the shop and to learn. It was very inexpensive, had professional shop level equipment, I learned safety, techniques, and which tools would be helpful for my eventual shop. After a few semesters, I kicked out the cars and started to turn my garage into a wood shop. I still consider going back when I can find the time to commit to a schedule again.

This forum post is now archived. Commenting has been disabled

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialRelated Posts

- Table saw blade is blowing wood when cross cutting it

- Blade marks when ripping

- The simplest workbench–when to upgrade?

- table saw cutting tapered when blade on an angle

- when to stain versus glue dovetail drawers

Categories

- Business

- Finishing

- General Discussion

- Hand Tools

- Jigs, Fixtures, Tips & Tricks

- Joinery

- New To Woodworking

- Power Tools and Machinery

- Project Plans/CAD Software

- SketchUp

- Turning and Carving

- Wood and Materials

- Workshop

Recent Posts and Replies

- |

- |

- |

- |

- |

- |

View the Library

Highlights

-

Shape Your Skills

when you sign up for our emails

Plus tips, advice, and special offers from Fine Woodworking. Newsletter Signup Sign UpSigning you up...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. See all newsletters -

Shop Talk Live Podcast

Shop Talk Live Podcast Our biweekly podcast allows editors, authors, and special guests to answer your woodworking questions and connect with the online woodworking community.

-

Our favorite articles and videos

Our favorite articles and videos We have created these special content collections organized to give you a deep dive into a range of topics that matter.

-

E-Learning Courses from Fine Woodworking

Join our trusted experts for these in-depth, online learning experiences.

- Sign Up for the New Woodworking Fundamentals Learn More

Your step-by-step introduction to the craft of woodworking.

-

Foundations of Woodworking Buy Now

Foundations of Woodworking Buy Now -

SketchUp for Furniture Design Buy Now

SketchUp for Furniture Design Buy Now

-

#322-Mar/Apr 2026

- Craig Thibodeau's Magical World of Puzzle Furniture

- Online Extras from FWW #322

- Q&A: If you have a quality miter gauge, why bother making a wooden sled?

-

#321-Jan/Feb 2026

- Simple Projects for Gifts, Donations, or Craft Shows

- Online Extras from FWW Issue #321

- Build a Glass-Top End Table

-

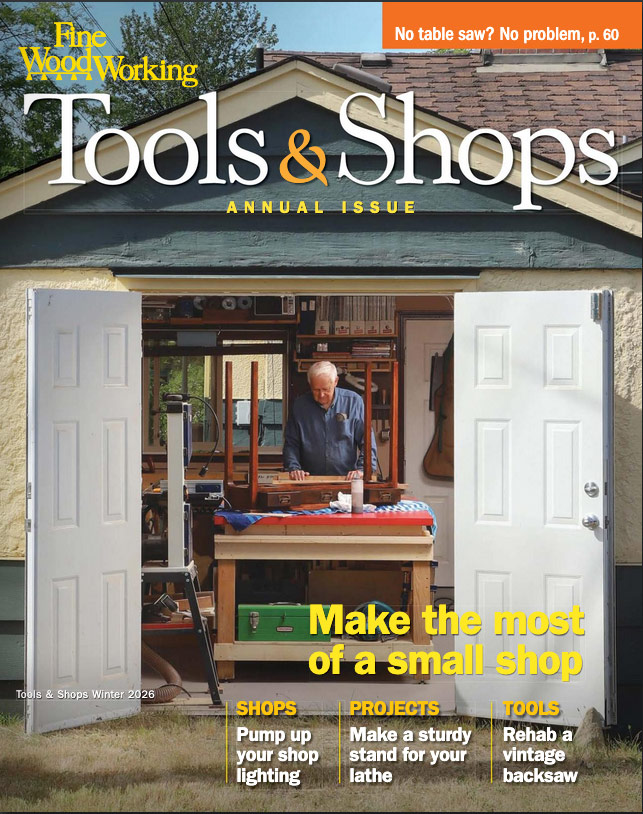

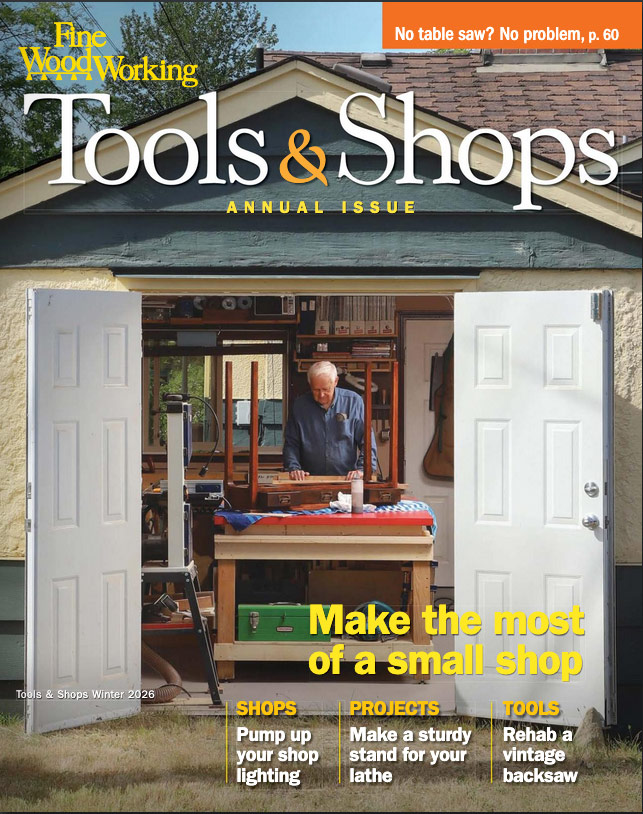

#320- Tools & Shops 2026

- Layout and Storage in a Small Shop

- Online Extras from FWW Issue #320

- From the Editor: Setting Up for Better Work

-

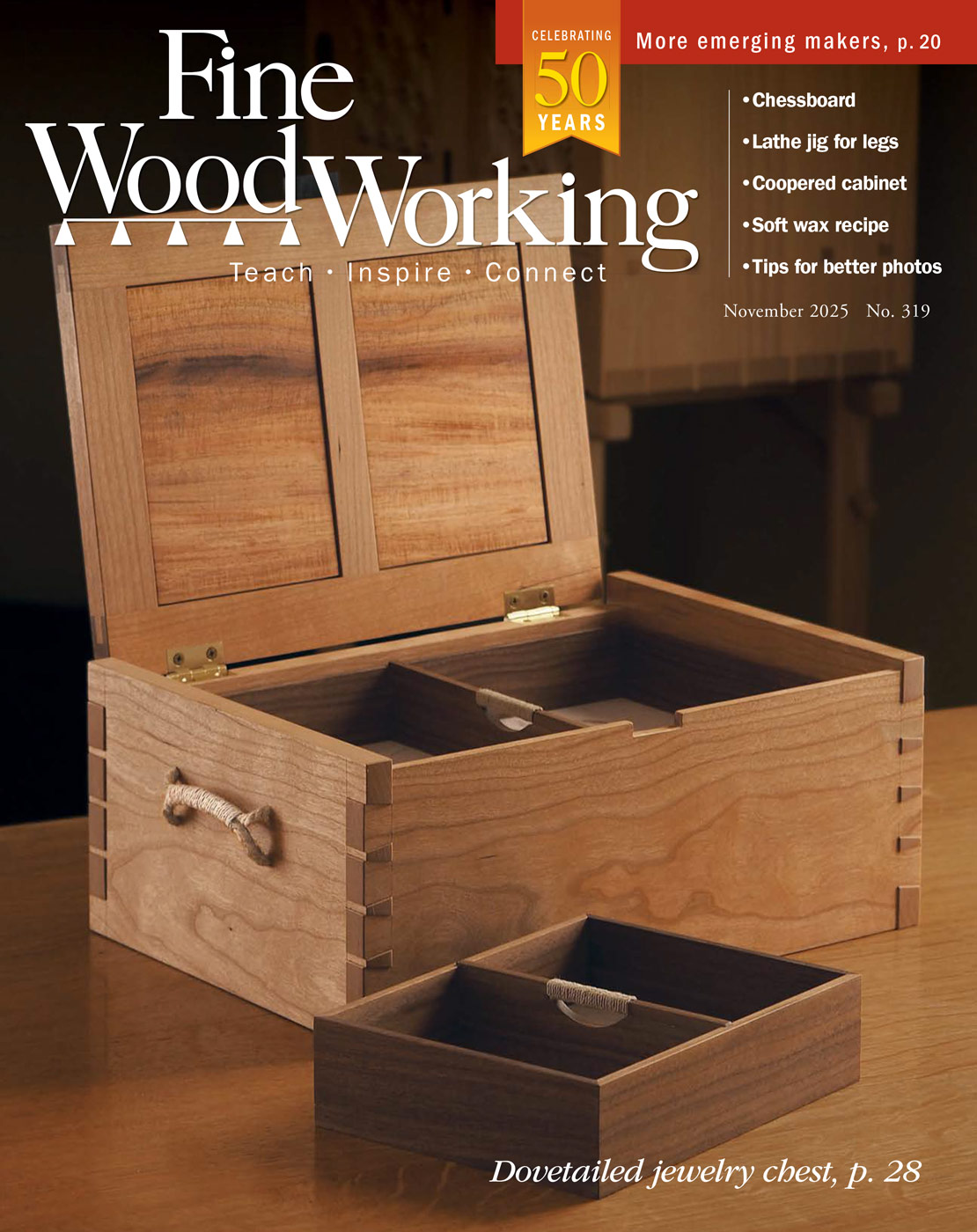

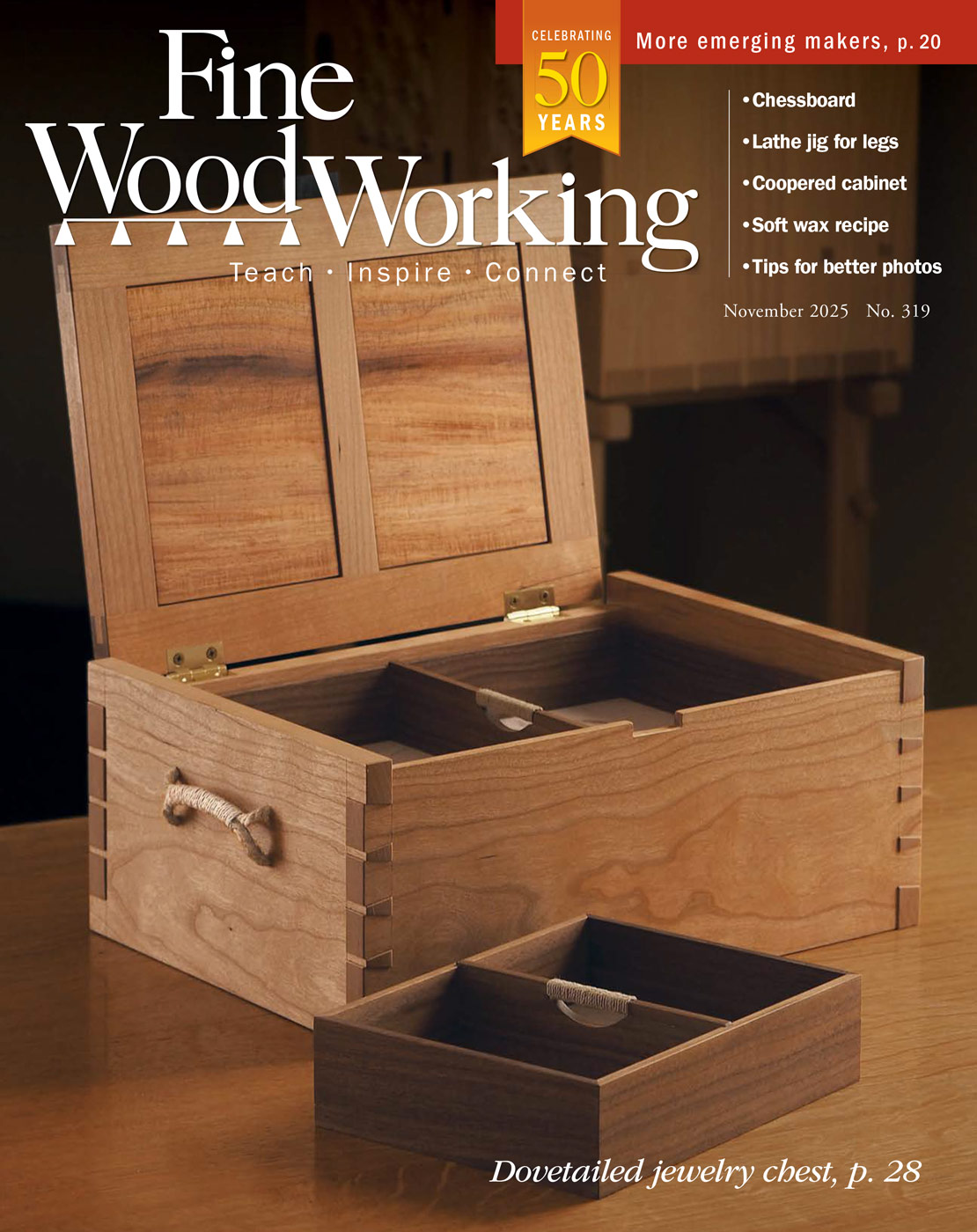

#319-October/November 2025

- Dovetailed Jewelry Chest

- Online Extras from FWW Issue #319

- Editor's Letter: Why No Wendell Castle?

-

#318-AUG/SEP 2025

- Techniques for Curved Molding

- Carved Entryway Mirror

- Knife Hinges Made Easy

UNLIMITED membership - Get access to it all

Start Free TrialGet instant access to over 100 digital plans available only to UNLIMITED members. Start your 14-day FREE trial - and get building!

Search Magnifying Glass Icon SearchMain Menu

- Projects and Plans

- How-To

- Shop Tips

- Tools & Materials

- Videos

- Gallery

- Magazine

- Video Workshops

- Members

- Forum

Popular Topics

- Design

- Small Projects

- Beds

- Chairs, Benches And Stools

- Built-ins

- Storage And Shelves

- Cabinets

- Carving

- Casework

- Desks

- Tables

- Shop Storage And Furniture

- Woodturning Projects

- Workbenches

- Surface Prep

More

- TV

- Forum

- Blogs

- Customer Support

Magazine

- Current Issue

- Past Issues

- Digital Libraries

- Magazine Index

- Subscribe

Membership

- Member Home

- Start Free Trial

- Gift Unlimited

- Log In

Online Learning

- Courses

- Webinars

- Podcasts

Events

- Fine Woodworking Live

- Fine Woodworking HANDS ON

Newsletter

Get woodworking tips, offers, and expert advice in your inbox Newsletter Signup GoSigning you up...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. See all newslettersFollow

UNLIMITED

Become an UNLIMITED member and get it all: searchable online archive of every issue, how-to videos, Complete Illustrated Guide to Woodworking digital series, print magazine, e-newsletter, and more.

Start Your Free Trial

Toggle Caption Previous NextMembers get unlimited site access.

To unlock this page, Start a Free Trial.Already a member? Log in

Tag » How To Get Into Woodworking Without A Garage

-

How To Get Into Woodworking Without A Garage - WikiHow

-

How To Start Woodworking In A Basement Or Apartment

-

Woodworking Without A Garage/workshop? - Reddit

-

How To Get Into Woodworking Without A Garage - Wiki How To English

-

How To Get Into Woodworking Without A Garage ... - CGAA

-

Getting Started In Woodworking With No Tools

-

Woodworking Without A Shop Or Garage - Dream Outdoor Living

-

5 Ways To Build DIY Furniture When You Don't Have A Workshop

-

How Do I Get Into Woodworking Without Losing A Finger?

-

5 Ways To Do Projects When You Don't Have A Full-Fledged Workshop

-

How To Start Woodworking On A Budget - YouTube

-

NO GARAGE? BUILT MY OWN WOOD SHOP!! - YouTube

-

How To Get Started Woodworking If You Live In An Apartment/don't ...

-

How To Start Woodworking - Just Tools