Acceptable Quality Limit - Sampling Table | AQL Standard - QIMA

Có thể bạn quan tâm

Table of Contents

Acceptable Quality Limit (AQL)

How Do I Determine the Correct Sample Size and Acceptance Number?

AQL Sampling Simulator

Table A

Table B

Ready to Simulate Your AQL Sampling

More Resources

Need more information?

Select your countryAfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguilla (UK)AntarcticaAntigua And BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBarbudaBelgiumBelizeBeninBermudaBhutanBoliviaBosniaBotswanaBrazilBritish Virgin Islands (UK)BruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCentral African RepublicChadChileChinaColombiaComorosCongoCook IslandsCosta RicaIvory CoastCroatiaCuracaoCyprusCzech RepublicDenmarkDiego GarciaDjiboutiDominicaDominican RepublicEaster IslandEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFijiFinlandFranceFrench GuianaFrench PolynesiaGabonGambiaGeorgiaGermanyGhanaGibraltar (UK)GreeceGreenlandGrenadaGuadeloupe (France)GuamGuatemalaGuineaGuinea-BissauGuyanaHaitiHondurasHong Kong SAR ChinaHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKorea (South)KuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacau SAR ChinaMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartinique (France)MauritaniaMauritiusMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserrat (UK)MoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNorthern Mariana Islands (US)NorwayOmanPakistanPalauPalestinePanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto Rico (US)QatarReunionRomaniaRwandaSaint Kitts And NevisSaint LuciaSaint Pierre And MiquelonSaint Vincent & The GrenadinesSan MarinoSao Tome & PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSomalilandSouth AfricaSpainSri LankaSurinameEswatiniSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTongaTrinidad And TobagoTunisiaTurkeyTurkmenistanTurks And Caicos Islands (UK)TuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamVirgin Islands (British)Virgin Islands (UK)Virgin Islands (US)YemenZambiaSelect your industryFood & Food PackagingBodycare Fashion & AccessoriesElectrical & Electronic ProductsGifts & PremiumsHomeware & GardenwareIndustrial Construction & Mechanical ItemsPrinting & PackagingTextile Apparel Footwear & AccessoriesToys & Recreational ItemsEyewearTechnical PartsLife Sciences Your question is about...Our services (prices, locations, products...)The QIMA websiteA current Order with QIMAA job applicationOther Receive supply chain insights and updates from QIMA. You can always unsubscribe and manage your email preferences later.Contact UsBy contacting QIMA you agree to our privacy policy and terms and conditions.

Acceptable Quality Limit (AQL)

The Acceptance Quality Limit (AQL) is used in product inspections to determine the maximum acceptable number of defective items in a sample batch. If the number of defective items is higher than the maximum acceptable limit, the batch is rejected. AQL is typically set differently for minor, major, and critical defects. Since critical defects are unacceptable, AQL for critical defects is commonly 0.

In sampling inspections, QIMA inspectors follow the ISO 2859 standard, which forms the basis for the Acceptable Quality Limit (AQL) methodology. The standard provides tables to determine sample sizes and defect thresholds, ensuring precise and reliable quality assessments.

Our inspectors use pre-defined sampling plans to perform a detailed analysis of production samples, verifying whether they meet the AQL. Our transparent, AQL-based approach to sampling inspections helps you make informed decisions on whether to accept or reject an entire batch.

AQL Benefits

Inspecting a sample of products from a batch in a consistent and systematic way, instead of testing every single item, provides significant benefits:

Saves time and reduces costs while still maintaining acceptable quality standards.

Helps balance the risk of accepting defective products against the cost and effort of inspection.

Allows different AQL levels for different products or defect types, supporting varying quality requirements.

Provides clear criteria for accepting or rejecting a batch, simplifying the decision-making process.

How do I Determine the Correct Sample Size and Acceptance Number?

Our experts will guide you in selecting the inspection level and AQL values that best fit your requirements. Use our AQL sampling calculation tool to simulate product inspections and gain a better understanding of how the process works.

For example, if you need to inspect 4,000 face masks using a normal inspection (Level II with an AQL of 2.5), simply enter the relevant data into the designated fields in the AQL calculator below:

Quantity: 4000

Inspection level: General Inspection II

AQL: 2.5

AQL Sampling Simulator

Aql Sampling SimulatorQuantityInspection LevelIIIIIIS1S2S3S4Critical DefectsSelect AQLNot Allowed0.0650.100.150.250.400.651.01.52.54.06.5Sample Size:0

Accept Point:0

Reject Point:0

Major DefectsSelect AQLNot Allowed0.0650.100.150.250.400.651.01.52.54.06.5Sample Size:0

Accept Point:0

Reject Point:0

Minor DefectsSelect AQLNot Allowed0.0650.100.150.250.400.651.01.52.54.06.5Sample Size:0

Accept Point:0

Reject Point:0

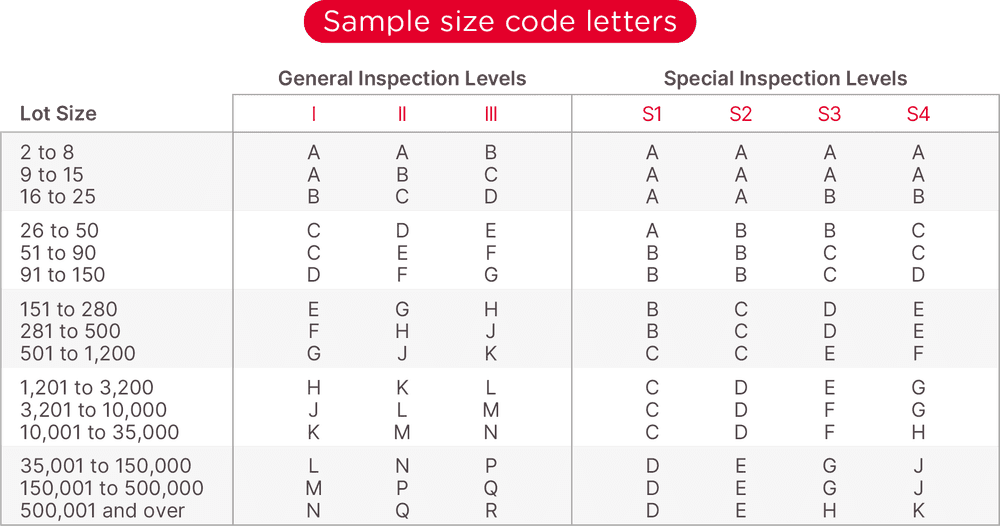

Table A

Find the respective Lot Size (quantity) and general inspection level: Code letter L Note: The AQL tables below are based on the ANSI/ASQ Standard Z1.4 – 2008

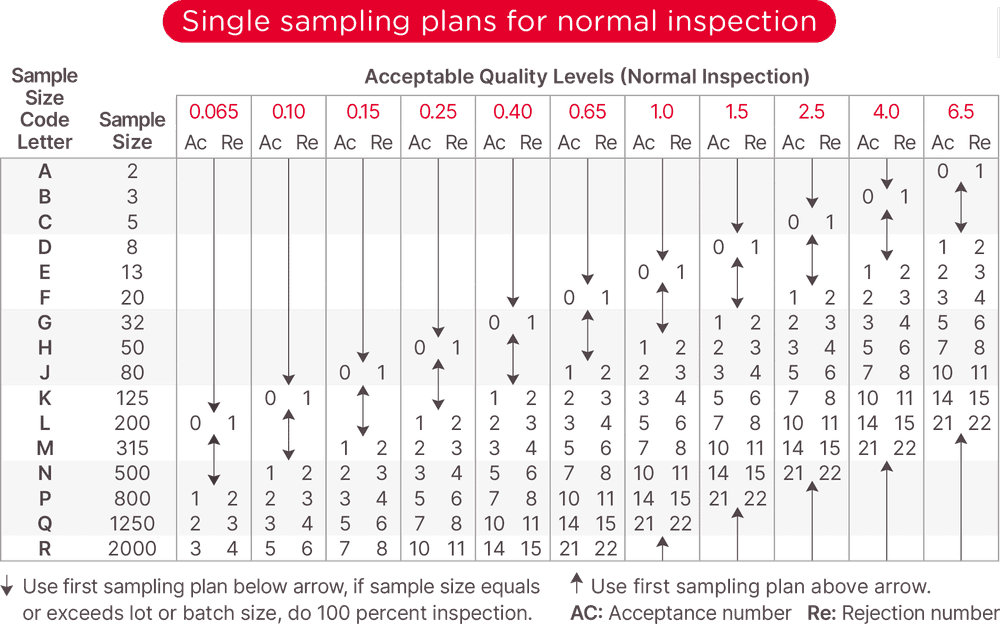

Table B

Locate Row L (the required sample size of 200) In compliance with AQL 2.5, no more than 10 units from a sample size of 200 may fail the inspection.

Simulate Your AQL Sampling

Go ahead and simulate your next sampling inspection:

Enter your shipment lot quantity

Select General/Special inspection level

Select AQL for all defects (critical, major, minor)

Refer to Tables A and B above to see the impact on inspected quantities and accepted defect limits

More Resources

Product Inspections

Initial Production Check (IPC)

During Production Check (DUPRO)

Container Loading Check (CLC)

Pre-Shipment Inspection (PSI)

Production Monitoring (PM)

Từ khóa » Tiêu Chuẩn Aql 2.5

-

Biểu đồ Chất Lượng AQL Chấp Nhận Trong Công Nghiệp Dệt May Thời ...

-

AQL Chart Trong Dệt May Và Sản Phẩm Tiêu Dùng

-

Đi Tìm Hiểu Aql 2.5 Là Gì ? Những Thông Tin Bạn Cần Nắm Rõ Về ...

-

Tiêu Chuẩn AQL Trong Quản Lý Chất Lượng - ITG Technology

-

[AQL Là Gì?] Acceptable Quality Level - Bạn Cần Biết Gì Về Nó?

-

MẪU AQL TRONG GIÁM ĐỊNH CHẤT LƯỢNG - HQTS

-

AQL Training Kiểm Tra Chất Lượng Theo Tiêu Chuẩn AQL - Tài Liệu Text

-

Biểu đồ Chất Lượng AQL Chấp Nhận Trong Công Nghiệp Dệt May

-

Mức độ Chất Lượng Chấp Nhận được - AQL Là Gì? - 123Job

-

Acceptable Quality Level (Aql) Là Gì - Christmasloaded

-

[PDF] Advantage Co., Ltd. Quality In Quality Control And Inspection Services

-

Yêu Cầu AQL Khách Hàng Target - Prezi