Basic Quality Control Concepts

Có thể bạn quan tâm

In this article, I explain three fundamental concepts that every buyer should be familiar with when it comes to quality control and inspections:

- Inspection levels

- The AQL

- When to inspect?

After 10 minutes, you will be able to (1) understand the reliability of an inspector’s findings and (2) take more informed decisions based on an inspection report.

What is Quality Control?

From the buyer’s perspective, quality control activities help confirm that a batch of products meet specifications. The most common activity is the final inspection, which means checking some products against a checklist, and getting to a pass/fail result.

The 3 Fundamental QC Concepts

If you have not started doing professional quality control, you will need to understand these 3 concepts to make sure the QC inspection plan meets your needs and that you obtain products which reach your expectations from your suppliers in Asia.

1. Inspection levels

Read and clip the slides for the above video on inspection levels here.

Why use random sampling?

Shipments often represent thousands of products. Checking 100% of the quantity would be long and expensive. A solution is to select samples at random and inspect them, instead of checking the whole lot.

But how many samples to select? On the one hand, checking only a few pieces might prevent the inspector from noticing quality issues; on the other hand, the objective is to keep the inspection short by reducing the number of samples to check.

The relevant standards propose a standard severity, called “normal level”, which is designed to balance these two imperatives in the most efficient manner.

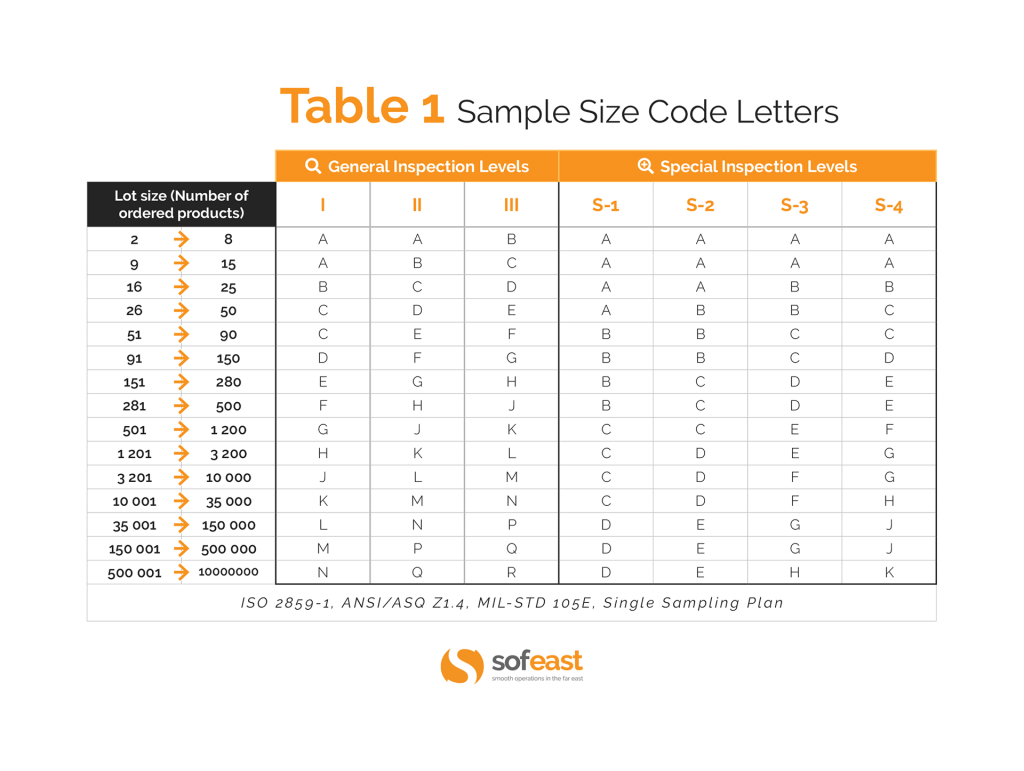

Within this normal severity, there are three general levels: I, II, and III. Level II is used for more than 90% of inspections. For example, for an order of 8,000 products, only 200 samples are checked.

Military Standard 105 was created by the US Department of Defense to control their procurements more efficiently. In 1994 they decided to rely on non-governmental organizations to maintain this type of standard. The ANSI, ISO, and other institutes all created their own standard, but in essence, they are similar. The major third-party QC firms use the same standards and the same statistical tables.

When to adopt a different level?

Suppose you source a product from a factory that often ships substandard quality. You know that the risk is higher than average. How to increase the discriminating power of the inspection? You can opt for level III, and more samples will be checked.

Similarly, if a supplier has consistently delivered acceptable products in the past and keeps its organization unchanged, you can choose level I. As fewer samples have to be checked, the inspection might take less time and be cheaper.

The relevant standards give no indication about when to switch inspection levels, so most importers rely on their “gut feeling”. (Not to be confused with the severity — I wrote about this here.)

The “special levels”

Inspectors frequently have to perform some special tests on the products they are checking. In some cases the tests can only be performed on very few samples, for two reasons:

- They might take a long time (e.g. doing a full function test as per claims on the retail box).

- They end up in product destruction. (e.g. unstitching a jacket to check the lining fabric).

For these situations only, the inspector can choose a “special level”.

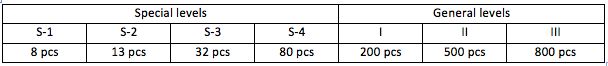

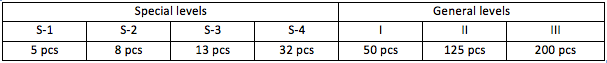

So we have three “general” inspection levels, and four “special levels”. For a given order quantity, each level gives a different number of samples to check. Let’s see how it plays in two examples.

Example 1: you order 40,000 products

The number of samples to draw varies from 8 to 800. Depending on the level you choose, the inspection might take only one inspector for one day, or up to 4 or 5 days of work.

Example 2: you order 3,000 products

Note: do not mix up “inspection levels” (I, II, III, S-1, S-2, S-3, S-4) and “inspection severity” (reduced, normal, tightened). They are different concepts. The above examples are based on a “normal” severity.

2. The AQL (Acceptance Quality Limit)

Read and clip the slides for the above video on the AQL here.

In part 1, we explained the different inspection levels that can be used. Another basic concept rings familiar to many importers but is often not clearly understood: the AQL (Acceptance Quality Limit).

There is no such thing as zero defect

First, as a buyer, you have to know what proportion of defects is tolerated on your market. If you are in the aviation business, any defective part might cause a disaster, so your tolerance will be very, very low. But you will have to accept a higher percentage of defects if you source consumer products that are assembled by hand in China or in India.

An objective limit is necessary

So, how many defects are too many? It is up to you, as a buyer, to make this decision. There are two reasons why you should not leave this to the inspector’s judgment:

- When it comes to giving instructions to an inspector, you should never leave gray areas—as they might open the door to corruption.

- Your supplier should have clear criteria for acceptability, or they will see rejections as unfair.

The AQL is the proportion of defects allowed by the buyer. It should be communicated to the supplier in advance.

The three categories of defects

Some defects are much worse than others. Three categories are typically distinguished:

- Critical defects might harm a user or cause a whole shipment to be blocked by the customs.

- Major defects are not accepted by most consumers, who decide not to buy the product.

- Minor defects also represent a departure from specifications, but some consumers would still buy the product.

For most consumer products, critical defects are not allowed, and the AQL for major defects and minor defects are 2.5% and 4.0% respectively.

Some important remarks:

- A professional inspector will notice defects and evaluate their category by himself. But it is better if the buyer himself describes the most frequent defects and assigns categories to each one.

- Defects can be on the product itself, on the labeling or on the packaging.

- If one sample presents several defects, only the most severe one is counted.

How to read the AQL tables

The master tables included in the relevant standards are commonly called AQL tables. Let’s take an example.

You buy 8,000 widgets from a factory, and you choose inspection level II. In the table below (which is only valid for single sampling plans), you see that the corresponding letter is L.

AQL table 1 (sample code letters):

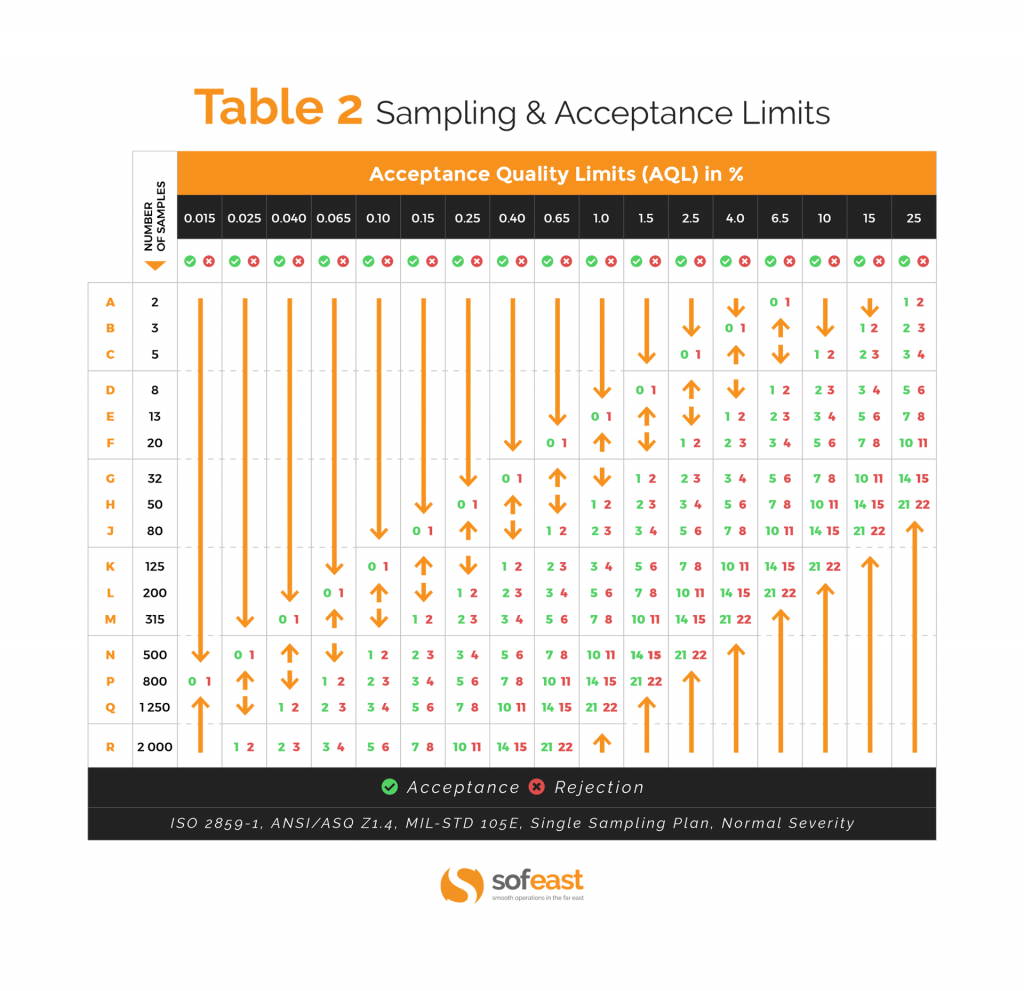

Now let’s turn to the next table (which is only appropriate for normal-severity inspections). The letter L gives you the number of samples to draw at random: 200 pcs.

And what about the AQL? Let’s say you follow the usual practice of tolerating 0% of critical defects, 2.5% of major defects, and 4.0% of minor defects. The maximum acceptable number of defects is 10 major and 14 minor. In other words, the inspection is failed if you find at least 1 critical defect and/or at least 11 major defects and/or at least 15 minor defects.

AQL table 2:

Notes:

- These 2 tables are only useful for inspections under normal severity. See all the tables for single sampling on AQL tables.

- More information about the AQL here.

Additional notes, for accuracy

- The number of defects is not the only cause for acceptance of refusal. The products can be refused because they do not conform to the buyer’s specifications, even though their workmanship is very good.

- If you have two different products (made with different processes or in different factories), you should do two separate inspections. If you inspect them together, one product might be accepted even though it presents too many defects. Why? Because the better workmanship of the other product might “compensate” for its poor quality.

3. When to inspect?

Read and clip the slides for the above video on the product inspections here.

The first two parts focused on the different inspection levels and on the AQL tables. So you know how to set the number of samples to check and how many defects have to be accepted. With these settings and your detailed product specifications, a QC inspector can check your products and reach a conclusion (passed or failed).

But importers face one more question: when should the products be inspected? This is an extremely important issue for buyers willing to secure their supply chain. Spending a few hundreds of dollars to check and fix issues early can be an excellent investment; if might save you weeks of delay, shipments by air, and/or lower quality products that you have to accept and deliver to your own customers.

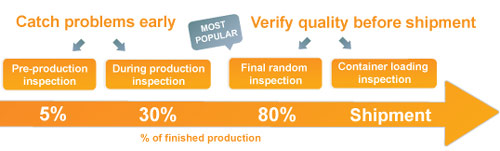

Four types of inspections

Let’s picture the simplified model where one factory turns raw materials into finished products. (If you also have to manage the quality of sub-suppliers’ products, the same model can be applied to them)

Pre-production inspection

This type of inspection is necessary if you want to check the raw materials or components that will be used in production. Buying cheaper materials can increase a factory’s margin considerably, so you should keep an eye on this risk. It can also be used to monitor the processes followed by the operators.

During production inspection

This inspection allows you to get a good idea of average product quality, and to ask for corrections if problems are found. It can take place as soon as the first finished products get off the line, but these samples might not be representative of the whole order. So usually an inspection during production is done after 10-30% of the products are finished.

Final (pre-shipment) inspection

Inspecting the goods after they are made and packed is the standard QC solution of most importers. The inspector can really check every detail, including counting the total quantity and confirming the packaging. Final inspections are usually performed in a hurry, just before shipment. To avoid creating delays, inspectors can usually start after all products are finished and 80%+ of the shipment quantity is packed.

Loading supervision

In some cases, a buyer wants to make sure the factory ships the right products, in the right quantity, and with the right loading plan.

Further reading about the different types of inspections: quality inspection services.

4. Putting it all together

Example 1: 5,000 widgets from a new supplier

You have no information about the factory, so you should adopt level II.

The order quantity is comprised of between 3,201 and 10,000pcs. In the first AQL table (higher in this document), you see the code letter is L.

And in the second AQL table, you see that 200 samples have to be checked by the inspector.

If you opt for the standard AQL limits (0 C. / 2.5% M. / 4.0% m.), the inspection is failed if at least one of these conditions comes true:

- One or more critical defects are found

- Eleven or more major defects are found

- Fifteen or more minor defects are found

And let’s say you want the inspector to check all the product functions on a few samples. This test takes some time. You can choose special level S-2. You see this test will be done on 8 samples.

Let’s say the 200 samples can be checked by one person in one day, so a third-party QC firm would quote you one man-day.

When to inspect? If this is a standard product and you have flexibility with timing, a final (pre-shipment) inspection should be enough.

Example 2: 30,000 watches from an unknown factory(ies)

You suspect that your supplier gave orders to several workshops to produce your goods, but he won’t tell you. And these items are rather valuable. A level-III inspection is probably the most appropriate.

If we read the AQL tables as we did above, we have to inspect 500 samples, and the maximum number of defects is: 0 critical, 21 major, 21 minor.

If a visual check on all samples and a function/accuracy check on a few pieces is enough, it probably takes two or three man-days.

When to inspect? If the supplier refuses to disclose the factory information, you have to go for a final (pre-shipment) inspection.

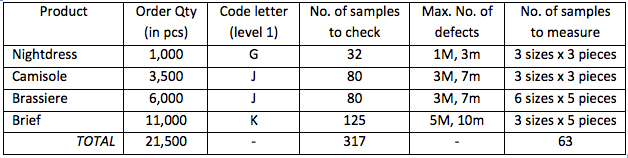

Example 3: four different styles of garments from a good factory

You know that this factory’s workmanship is quite good. But you want an inspector to check all the conformity elements and in particular the measurements. Level I should be enough.

You sell these products in boutiques at a high price, so you can only accept 1.5% major defects (M) and 4.0% minor defects (m). Note: for garments, there are generally no critical defects.

The fitting is quite important, especially for the brassiere and the brief, so 3 to 5 samples should be measured in each size.

There are 4 different types of products, so there have to be 4 inspections:

The total number of samples to check visually is 317 pieces. And 63 of these samples also have to be measured. So it will probably take 2 inspectors (maybe 3, depending on the complexity of the products) for one day.

When to inspect? The best is clearly during production after enough finished products have come off the lines. As the 4 products might not all be processed at exactly the same time, it might be preferable to send an inspector at different times. And if an inspection is failed, a re-inspection can probably be performed at the supplier’s charge.

Related Quality Control Resources

Tired of reading long articles? See this illustration about Random Quality Inspections.

You will also like these resources that provide a huge amount of advice for importers who wish to improve quality:

- What is a Quality Inspection? Context, Tools & Template

- Four simple steps for starting to do quality control

- Quality Assurance VS Quality Control

- The 4 types of quality inspection services

- Quality Control Plan: Defining Expectations Before Production

- The Different Types Of Sampling Plans For QC Inspections

- What is the “AQL” (Acceptance Quality Limit) in simple terms?

- How to choose an AQL limit?

- The Special Inspection Levels in the AQL Tables

- Inspection during production: a necessity?

- Final Random Inspection: A Guide For Importers

- Benefits Of Quality Inspection Software For Quality Inspectors

- Benefits Of Quality Inspection Software For Managers

- Useful Templates For Importers (13 free templates)

Get expert help to improve YOUR product quality from suppliers in China or Vietnam. Read: Quality Assurance In China Or Vietnam For Beginners

Grab your free copy of Sofeast’s eBook and learn the common traps new importers from China or Vietnam fall into, and how to avoid or overcome them in order to get the best possible production results. It also outlines a proven quality assurance strategy that you can follow in order to have better control over your product quality, covering:

- Finding Suitable Suppliers

- Defining your Requirements before Production Starts

- Don’t Skip the New Product Introduction Process

- Regular Quality Inspections (Trust but Verify)

- Tying Payments to Quality Approvals

Sounds good? Hit the button below to get your copy now:

28 Responses

Please send me 2.5 Aql,4.0 Aql satanderd table

Reply@ Muhammad: It’s not like there is one such table… You’d have to go through tables 1 and 2 above to get the correct values, and that’s only for single plans under normal level… In other words, these statistical tables are not user-friendly. You’d better use this free calculator: https://www.qualityinspection.org/sampling-plan/step1.php. I hope it helps!

ReplyDear sir/madam

Thank you for your site . But i want to know about AQL with ISO STANDER label What is AQL ???. and i want to know all buyer stranded AQL ????

Thanks shipon

ReplyHi Shipon, The AQL tables in the ISO2859-1 standard are identical to the tables I show on this page. For more in-depth info, you can go to https://knol.google.com/k/what-is-the-aql

ReplyDear sir / madam

i want to know about measurement stranded label also . i think measurement is a part of inspection so i need about measurement stranded label ?? please send me

if the quantity is 30000 pcs i know about AQL but don’t know How many pcs i can measurement in size is s , m , L , XL , Stranded

Thanks shipon

ReplyThere are different schools of thought about this. You can read this article: https://www.qualityinspection.org/garment-inspections-assessing-the-conformity-of-measurements/

ReplyDear sir

i want to know measurement tolerance ??? please send me

Thanks shipon

ReplyThis is entirely up to the buyer’s quality manager… I can’t help you with this, sorry.

Replyi want to know about fabric inspection roles ?????

ReplyYou mean, inspection of fabric rolls? It is totally different inspection procedure. Have a look at https://www.qualityinspection.org/inspection-of-fabric-rolls-in-china/

Replydear sir what is the rotter y print size and system ???? thaks Amir hossin

Replydear sir

what is the safety item for garments ?????

thaks Amir hossin

ReplyAmir, You can read this post: https://www.qualityinspection.org/inspection-textile-products

ReplyDear Sir, please send me the commitment to quality under 1:10:100 rule as soon as possible. Thank you very much for your attention regarding this matter!!!

Best Regards,

John Paul Climber

ReplyJohn Paul, I explained that concept on this page: https://knol.google.com/k/quality-control-the-three-types-of-inspections#An_important_concept(3A)_why_inspecting_earlier_is_generally_better

ReplyDear All, Any one can help me with Measurement AQL for Apparels. Can anyone pls let me know the procedures for measurement AQL.

Regards Abraham

ReplyAbraham, See part 1 of this article: https://www.qualityinspection.org/garment-inspections-assessing-the-conformity-of-measurements. You can also evaluate the measurements in another way: see part 2 of that same article.

ReplyDear Renaud,

Thanks for your reply.

I just want to know is there any specific AQL for measurement. For eg as per AQL 2.5 we take 80 pcs for quality inspection ( sampling plan ), out of 80 how many pcs we need to check for measurement. I will appreicate your kind reply. If you have any systamatic table for measurement aql pls send to me.

thanks Abraham

ReplyAbraham, I don’t understand your situation… What is the total quantity of products (ordered)? The AQL tables are higher on this page (see under “How to read the AQL tables?”.

ReplyHi Renaud,

Hi have similar question, I have been reading since few days ago, and I am confuse with the boutique example: There are 4 different types of products, so there have to be 4 inspections

“The total number of samples to check visually is 317 pieces. And 63 of these samples also have to be measured. So it will probably take 2 inspectors (maybe 3, depending on the complexity of the products) for one day”.

I understood sample according with lot size and AQL level, just I don’t understand from where we have to choose number of sampling to measure, this is confuse, could you please explain us?

And another think that I don’t find yet is how change from normal inspection to reduced inspection, and when we can apply skip lots or decide no inspection for any product. Could you please help me to understand?

Is here: https://qualityinspection.org/quality-control-basics/)

In ISO-2859 is clear how to change from normal to tightened, and from tightened to normal, but that I mention in last paragraph is difficult for me to understand.

Thank You Aracely

ReplyOh, the number of samples to measure does NOT come from the standard. It is set by the relevant authority (e.g. the buyer’s quality manager). And if you read the full ISO-2859-1 standard it explains how to switch from normal to reduced, based on the number of points.

Reply

pls send the LQC sampling plan for packaging.

ReplyPawan Kumar Pankaj, We don’t do this kind of testing, and I don’t have this information. Sorry.

ReplyIt’s great that you mentioned that being able to have the inspection before will save you from costly damages or issues in the future. With that in mind, I will make sure that my mother will be having her products inspected before releasing them. This would also save her from lawsuits. She just created a makeup line since she has been very fond about these things ever since she was a teen.

Reply“The relevant standards give no indication about when to switch inspection levels, so most importers rely on their “gut feeling”. Do the relevant standards here include the MLT-STD-105 since it has a switching rules to switch inspection levels ?

ReplyYes, the latest version of MIL-STD 105 and the commercial standards that replaced it. In ISO 2859-1, I read this: “Unless otherwise specified, level II shall be used. Level I may be used when less discrimination is needed or level III when greater discrimination is required. Four additional special levels, S-1, S-2, S-3 and S-4 are also given in Table 1 and may be used where relatively small sample sizes are necessary and larger sampling risks can be tolerated.” and “The inspection level required for any particular application shall be specified by the responsible authority. This allows the authority to require greater discrimination for some purposes and less for others”. The switching rules are for the severity, not the level. More about this distinction on https://qualityinspection.org/statistical-inspection-levels-severity/.

Reply

My uncle told me that he won a building project and he needs to perform the job perfectly so that he can make his company grow. I like how you said that an inspector can help you notice any defects on the job done. I will suggest to him to contact a material testing company so that they can grade the quality of the job and material.

ReplyThe article is very informative which is worth reading it.

Reply

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Comment *

Name *

Email *

Website

Save my name, email, and website in this browser for the next time I comment.

Weekly updates for professional importers on better understanding, controlling, and improving manufacturing & supply chain in China.This is a blog written by Renaud Anjoran, an ASQ Certified Quality Engineer who has been involved in chinese manufacturing since 2005.

He is the CEO of The Sofeast Group.

Hit the button below to get in touch:

Contact Us!Subscribe to our email newsletter

Connect with us

Envelope Facebook-f Linkedin-in Rss Twitter Youtube

Latest Articles

- 5 Manufacturing Trends You Should Know About in 2026

- Kickbacks and Middlemen in China Sourcing

- Can You Really Afford to Manufacture Your New Product?

- Avoiding Mold on Imported Products: Simple Packaging & Shipping Controls That Actually Work

- How to Hire a Quality Manager in China/Asia: Interview Questions That Reveal True ISO 9001 Competence

Categories

- Quality Control Tips

- Sourcing New Suppliers

- Supplier Management

- New Product Development

- Process Improvement

- Ethical Sourcing

Archives

Archives Select Month December 2025 November 2025 October 2025 September 2025 August 2025 July 2025 June 2025 April 2025 March 2025 February 2025 January 2025 December 2024 November 2024 October 2024 September 2024 August 2024 July 2024 June 2024 May 2024 April 2024 March 2024 February 2024 January 2024 December 2023 November 2023 October 2023 September 2023 August 2023 July 2023 June 2023 May 2023 April 2023 March 2023 February 2023 January 2023 December 2022 November 2022 October 2022 September 2022 August 2022 July 2022 June 2022 May 2022 April 2022 March 2022 February 2022 January 2022 December 2021 November 2021 October 2021 September 2021 August 2021 July 2021 June 2021 May 2021 April 2021 March 2021 February 2021 January 2021 December 2020 November 2020 October 2020 September 2020 August 2020 July 2020 June 2020 May 2020 April 2020 March 2020 February 2020 January 2020 December 2019 November 2019 October 2019 September 2019 August 2019 July 2019 June 2019 May 2019 April 2019 March 2019 February 2019 January 2019 December 2018 November 2018 October 2018 September 2018 August 2018 July 2018 June 2018 May 2018 April 2018 March 2018 February 2018 January 2018 December 2017 November 2017 October 2017 September 2017 August 2017 July 2017 June 2017 May 2017 April 2017 March 2017 February 2017 January 2017 December 2016 November 2016 October 2016 September 2016 August 2016 July 2016 June 2016 May 2016 April 2016 March 2016 February 2016 January 2016 December 2015 November 2015 October 2015 September 2015 August 2015 July 2015 June 2015 May 2015 April 2015 March 2015 February 2015 January 2015 December 2014 November 2014 October 2014 September 2014 August 2014 July 2014 June 2014 May 2014 April 2014 March 2014 February 2014 January 2014 December 2013 November 2013 October 2013 September 2013 August 2013 July 2013 June 2013 May 2013 April 2013 March 2013 February 2013 January 2013 December 2012 November 2012 October 2012 September 2012 August 2012 July 2012 June 2012 May 2012 April 2012 March 2012 February 2012 January 2012 December 2011 November 2011 October 2011 September 2011 August 2011 July 2011 June 2011 May 2011 April 2011 March 2011 February 2011 January 2011 December 2010 November 2010 October 2010 September 2010 August 2010 July 2010 June 2010 May 2010 April 2010 March 2010 February 2010 January 2010 December 2009 November 2009 October 2009 September 2009 August 2009 July 2009 June 2009 May 2009 April 2009 March 2009 February 2009 January 2009Từ khóa » Check Qc

-

Quality Control Checks Definition | Law Insider

-

Quality Control Definition & Example - Investopedia

-

What Is Quality Control (QC)? - TechTarget

-

'5 Essentials Of A Quality Control Checklist' EBook | InTouch

-

[Shopee Mall Return] How Long Is The Quality Check (QC) Process ...

-

How To Effectively QC Check Your Discovery Productions - Logikcull

-

Quality Assurance Vs Quality Control: Definitions & Differences - ASQ

-

QC Checker (No EXP Required; Training Provided)

-

Verify QC | VERIPOS

-

Introduction To Netflix Quality Control (QC)

-

QC-Check Software And Workstations - Outboard

-

QC Check Samples Reference Materials - LGC Standards

-

Quality Control (QC) And Accessibility Check (1 To 20 Pages): Store