CNC G Code: G02 And G03

Circular interpolation at a given feedrate.

G02 Clockwise arc motion at feedrate. G03 Counterclockwise arc motion at feedrate.

The clockwise direction is determined by viewing the arc from the positive side of a vector normal to the arc plane.

Like the G01 command, G02 and G03 require a feedrate (F) as well as destination (or distance) coordinates (X, Y, and/or Z). The feedrate will default to the current feedrate if it has been commanded previously in the program. For full circles, the X, Y and Z can be omitted (see I, J, K Method below).

The arc must lie parallel to a plane defined by two axes of machine motion. This plane must be set (usually in the program header) by G7, G18, G19.

There are two different ways to program a G02 or G03.:

I, J, K Method

This is the only method that can be used to program a complete circle. It can be used any time the R method could be used, but it is a little more complicated.

Only two of I, J, and K will be used. This will depend on what arc plane has been selected (see by G7, G18, G19).

- G17 – Use I and J

- G18 – Use I and K

- G19 – Use J and K

The I, J and K arguments specify the DISTANCE from the ARC START POINT to the CENTER POINT of the arc. Note that the start point of the arc is NOT GIVEN in a G02 or G03 command. The start point is determined by the location of the cutter when the command is implemented. Also, the center point is never given explicitly in the command. I, J, and K are DISTANCES. If the geometry of the circle is impossible (to within .0001), an error is usually thrown.

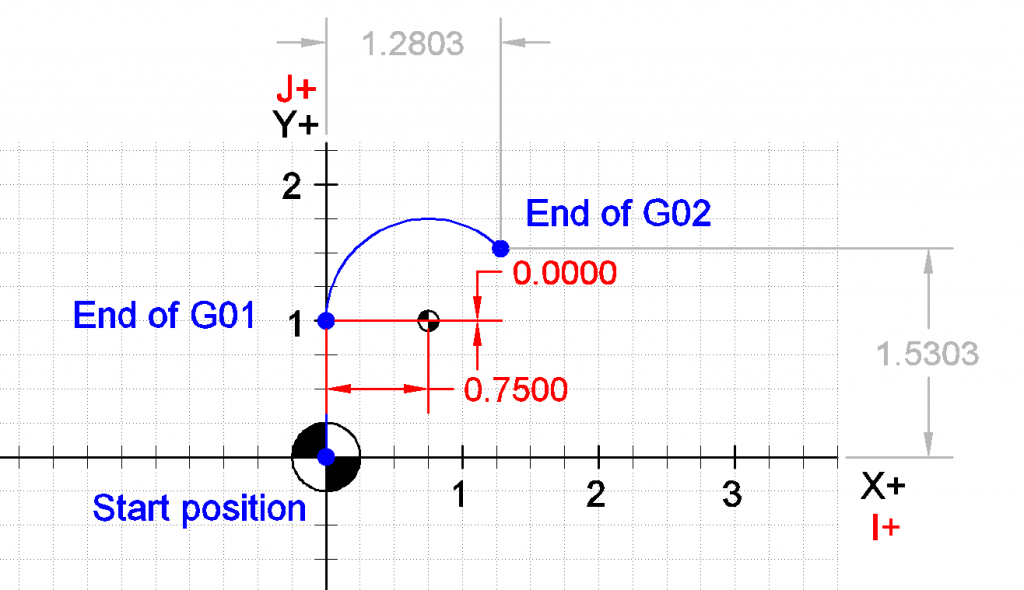

I, J, K Method Example 1:

Assume the machine is currently at X0.0 Y0.0 and G90 and G17 are enabled in the header.

G01 Y1.0 F8.0; G02 X1.2803 Y1.5303 I.750;Will produce the following toolpath. Notice the value for J (the distance in the Y axis) would be zero, it can be omitted:

Note: The value of i is 0.75 because it is that distance from the arc start point, not because it is that distance from the Y-axis.

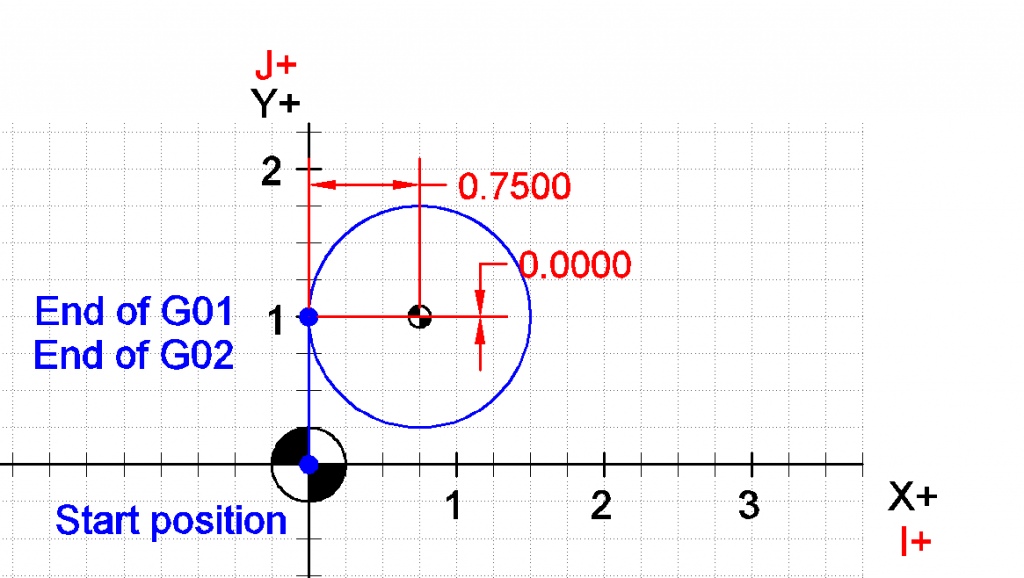

I, J, K Method Example 2:

To program a full circle, the end point is omitted from the G02 code. Again, assume the machine is currently at X0.0 Y0.0 and G90 and G17 are enabled in the header:

G01 Y1.0 F8.0; G02 I.750;

R Method

The R Method can only be used for arcs less than 360 degrees. As you might expect, the R address is used to specify the radius of the arc.

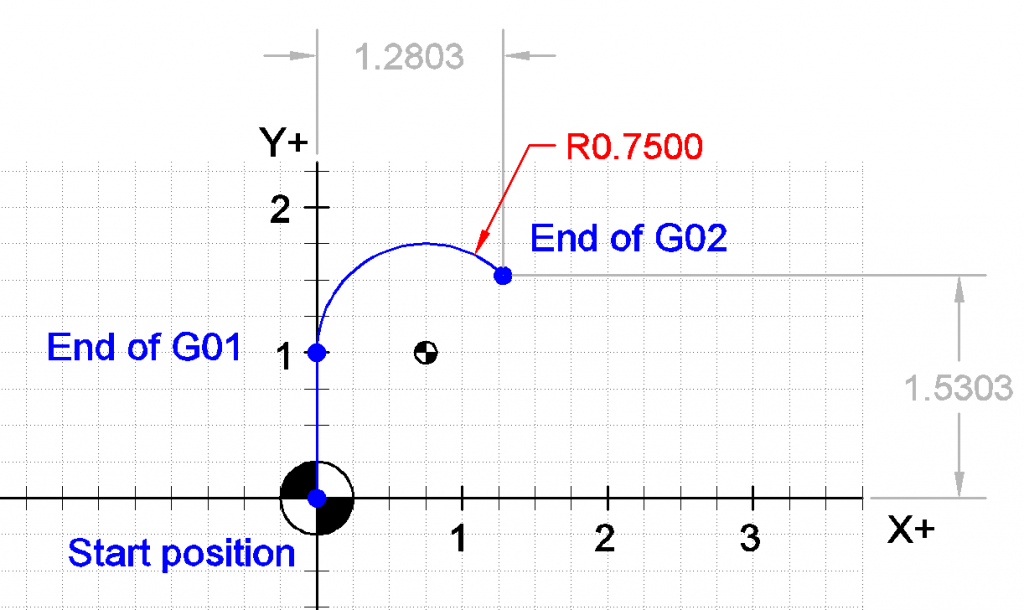

R Method Example 1:

Assume the machine is currently at X0.0 Y0.0 and G90 and G17 are enabled in the header.

G01 Y1.0 F8.0; G02 X1.2803 Y1.5303 R.750;

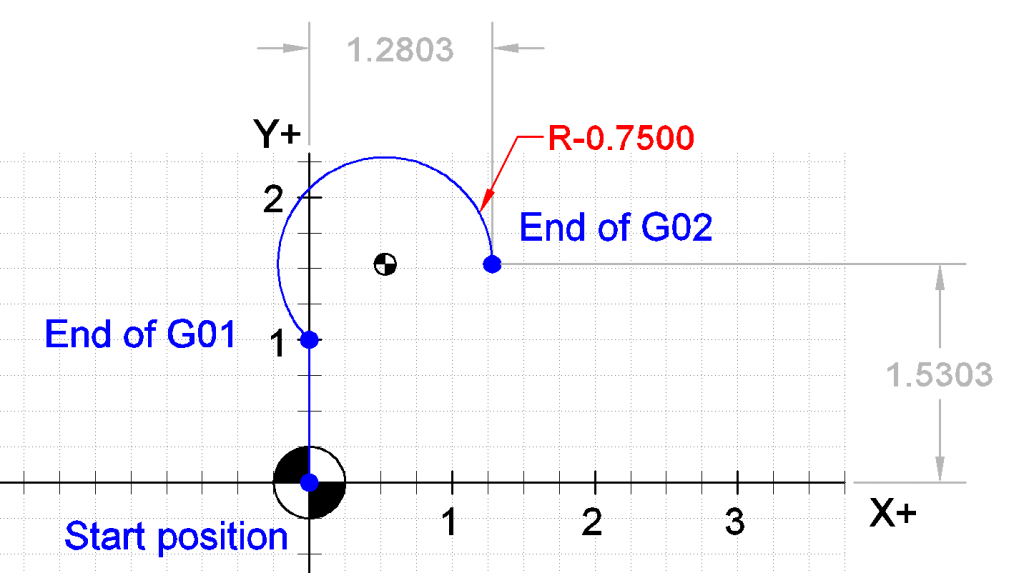

R Method Example 2:

Notice that there is actually another arc that meets the same criteria as the one in the example above. The other arc has a longer arc length but the same radius, start and end points. If we want the arc with the longer arc length, we use a -R value (since -R does not already have a valid meaning).

G01 Y1.0 F8.0; G02 X1.2803 Y1.5303 R-0.750;

See also: Haas Manual

Từ khóa » G2 G3 Cnc

-

Multiple Arc CNC Mill Program G2 G3 IJ

-

Quick G-Code Arc Tutorial: Make G02 & G03 Easy, Avoid Mistakes

-

G02 G03 Circular Interpolation - CNC Training Centre

-

Master Your CNC - HOW TO USE G1, G2 AND G3 CODES ON A ...

-

How Does G2,G3 Work?? - CNC Zone

-

CNC Mill G-Code | G2, G3 - YouTube

-

G02 CW / G03 CCW Circular Interpolation Motion (Group 01)

-

What Are The G0, G1, G2, And G3 G-Codes? (Detailed Analysis)

-

G1 Vs G2/G3 For CNC - Duet3D Forum

-

G Codes - LinuxCNC

-

Nội Suy Cung Tròn Trong Lập Trình Tiện CNC

-

Cnc Milling G2 G3 Code Sample

-

G2&G3 On Lathes - Narkive