Create Your Own Code - HAAS Automation UK

MENUMENU Book a Demo My Haas Search Create Your Own Code

MENUMENU Book a Demo My Haas Search Create Your Own Code Do you find that you regularly repeat the same lines of code in different programs – for a specific operation like positioning a tool in a hole before starting a cycle, or perhaps moving the machine to a certain load/unload position?

If so, then Haas engineers have a time saving feature installed in all Haas controls that will help you reduce the programming you have to do, whilst maintaining easy access from any program within the control.

The function is called Aliasing, is available on Haas mills and lathes and can be used for G or M codes depending on the user’s preference, here’s how it works:

Parameter 81 is for an M-code call of program number O9000, so for example if parameter 81 contains the value 37, when the control reads the M37 line in the program it would call program O9000 and run it, before returning to the original program and continuing from the line after the M37 call.

So we would have;

O0001; T1 M06; G0 G90 G54 X0. Y0. S1500 M03; G43 H1 Z50. M8; . (Run normal program) . . M37; (Call O9000 program which positions table for easy load/unload of large part) M30;Parameter 81 through 90 are for M-codes and refer to program numbers O9000 through O9009, with parameters 91 through 100 referring to G-codes and specifically program numbers O9010 through O9019.

Note: if a code is used that already exists within the standard G or M codes, such has G84, then the aliased program command will take precedence and in this instance the tapping cycle would be ignored. Also be aware that some probing systems utilise the O9xxxx series program numbers for their own cycles and care should be taken in this regard.

Haas applications engineers are available to assist if you have difficulties or refer to the original manuals supplied with your machine.

Control Options

- Improve Your Cutting Finish

- Speed Up Your Tapping Cycle

- Operator Checking Questions

- Reduce Energy Consumption

- Add an Extra Axis – the Easy Way

- Tool Life Expectancy

- Advanced Tool Management

- Turn on to Tool Monitoring

- Protect Your Tools

- Material Assistance

- Create Your Own Code

- Tapped Holes in all Directions

- Who Changed the Program?

- Who Changed the Program?

- Programmable Offsets

- Taking the Most Direct Route

- Varying Accuracy

- Smooth Operator

- Cylindrical Mapping

- Perfectly Written?

- Help with Different Languages

- Help with the Decimal Points

- Turning off the lights

- Keeping Everything Together

- Showing Only the Offsets in Use

- Setting 88 to prevent overrides

- Using G-Code for Circular Milling

- Extra Tools

- Inverse Time Feed Mode (G93)

- Helical Motion Enhancement

- Electronic Thermal Compensation (ETC)

- Screen Capture

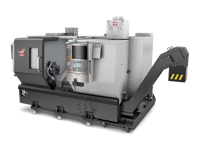

VF-1 & HRC210 Fits with a Traditional Setup

Caution: This Rotary May FitFor Example: When a rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. We have labeled this particular rotary and mill combination with a yellow caution

- The size of rotary

- The size of the mill table and the machine's travels

- The space between the mill table and sheetmetal enclosure

You can design and build your own sub-plate using the dimensions of your Haas mill and the dimensions of the rotary you'd like to use on that mill. Product dimensions are available for every machine and rotary on this website.

Dimensions1 Dimensions2 Rotary Type: Single-Head RotarySingle-Head Rotary Tables and Indexers are usually mounted to the right side of the table, with the rotary facing the centre of the machine. This is the basic setup we used to determine the fit of your rotary product.

Image shown for mounting example purposes only. Your actual rotary and mill appearance may differ.

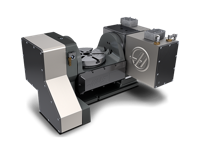

Rotary Type: Tilting/TrunnionTrunnion Tables, T5Cs, and TRTs are usually mounted in the centre (or slightly off-centre) of the mill table. If you are using probing on the mill, be aware of the interference with larger tools, especially during tool changes.

NOTE: Trunnion units present interference issues with the swing of the unit relative to the machine column and spindle head.

Image shown for mounting example purposes only. Your actual rotary and mill appearance may differ.

Rotary Type: Multi-Head RotaryMulti-Head Rotary Tables and Indexers are usually mounted toward the back of the table, with the indexer heads or platter facing forward. To mount a multi-head rotary in a different orientation, you must use alternative fixturing.

Image shown for mounting example purposes only. Your actual rotary and mill appearance may differ.

Important Information:

4-axis machines cannot use dual-axis rotaries. Some options may affect mounting (EC-1600 4th-Axis Table, Low-Profile Tables, Table Spacers, Column Risers, etc. Tool Changers: SMTCs and umbrella tool changers both present interference issues, plan appropriately.

X

Từ khóa » G0 G90 G54 X0 Y0

-

How Would I "Home" To G54? : R/CNC - Reddit

-

SUMMARY OF G-CODES - MachMotion

-

Learn G28 X0. Y0. Z0. G-code - With Examples - Cnc Philosophy

-

Unit 4: CNC Language And Structure – Manufacturing Processes 4-5

-

G54, G52, And G92 G-Codes: Work Offsets For CNC Fixtures

-

G90 And G91 G-Codes - Absolute And Incremental

-

[PDF] Cnc G-code Example Program

-

G Codes - LinuxCNC

-

CNC Work Offsets G54 To G59 How To Use Them

-

Produce G-Code For Profiling – Digital Design & Fabrication

-

[PDF] Examples Manual Mill Model

-

Cracking The Code | Cutting Tool Engineering

-

G92 Set Work Coordinate Systems Shift Value (Group 00)

-

Need Help! G28 To G54 - CNC Zone