G68.2 *basic* Explanation - Industrial Forum

Welcome to eMastercam

Welcome to eMastercam Register now to participate in the forums, access the download area, buy Mastercam training materials, post processors and more. This message will be removed once you have signed in.

Use your display name or email address to sign in:

- Sign In

- Sign Up

- All Activity

- Home

- Forums

- Mastercam Forums

- Industrial Forum

- G68.2 *basic* explanation

By Newbeeee™, December 16, 2010 in Industrial Forum

Share More sharing options... Followers 1- Reply to this topic

- Start new topic

- Prev

- 1

- 2

- 3

- Next

- Page 1 of 3

Recommended Posts

Newbeeee™

Posted December 16, 2010Newbeeee™

-

- Verified Members

-

- 3.6k

- Location:Where the Ind Revolution began

Hi all,

A friend of mine is working on a MAM72.

It has G68.2 and he can't get his head around how it works.

Can someone please explain in laymans basic terms how this works?

Many thanks as always.

- Quote

Link to comment

Share on other sites

- Replies 68

- Created 15 yr

- Last Reply Sep 12

Top Posters In This Topic

-

7

-

6

-

5

-

4

Popular Days

-

Dec 17

12

-

Jun 4

9

-

Dec 18

7

-

Feb 6

6

Top Posters In This Topic

-

crazy^millman 7 posts

-

Newbeeee™ 6 posts

-

Joe788 5 posts

-

Colin Gilchrist 4 posts

Popular Days

-

Dec 17 2010

12 posts

-

Jun 4 2014

9 posts

-

Dec 18 2010

7 posts

-

Feb 6 2019

6 posts

Popular Posts

Alex Dales

September 12, 2025

I very recently created this demo video that allowed me to show the Euler rotation with G68.2 directly in Machsim. G68_2 Euler Rotation.mp4 G68.2 uses an intrinsic rotation, meaning that

Delcandoit

February 14, 2014

I looked at this topic last Saturday and it baked my noodle. I went home and read the Wikipedia link from Colin, watched many Khan Academy videos, reread the Wikipedia link from Colin, visited all oth

Newbeeee™

November 19, 2013

James - print it off and put it in a yellow binder and sell it to fanuc as an addendum to their manuals. This would really help probably 99% of the world using their 5axis controls!

Posted Images

Guest SAIPEM

Posted December 17, 2010Guest SAIPEM

-

- Guests

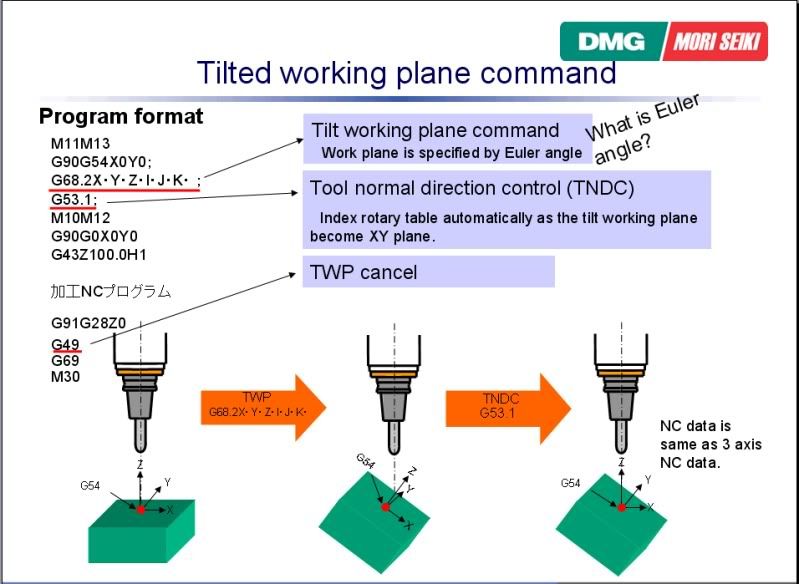

Fanuc 68.2 allows a user to define a WorkPlane by an X,Y,Z Coordinate Origin and the angular rotation about X,Y,Z axis centerlines(I,J,K Addresses)

The benefit of this for machines with a nutating head is that you can use all the canned cycles while the head is tilted.

You can also generate 2-1/2D toolpaths with arcs without having them linearized because of the plane orientation.

G68.2 performs the sames funtionality as the Fanuc 3-D Coordinate Conversion using G68 but simplifies it to a single line of code.

G68 3-D Coordinate Conversion required 2 lines of code to activate.

- Quote

Link to comment

Share on other sites

Mgrenier

Posted December 17, 2010Mgrenier

-

- Verified Members

-

- 765

- Location:Trois-Rivières, Québec, Canada

OK, here it goes,

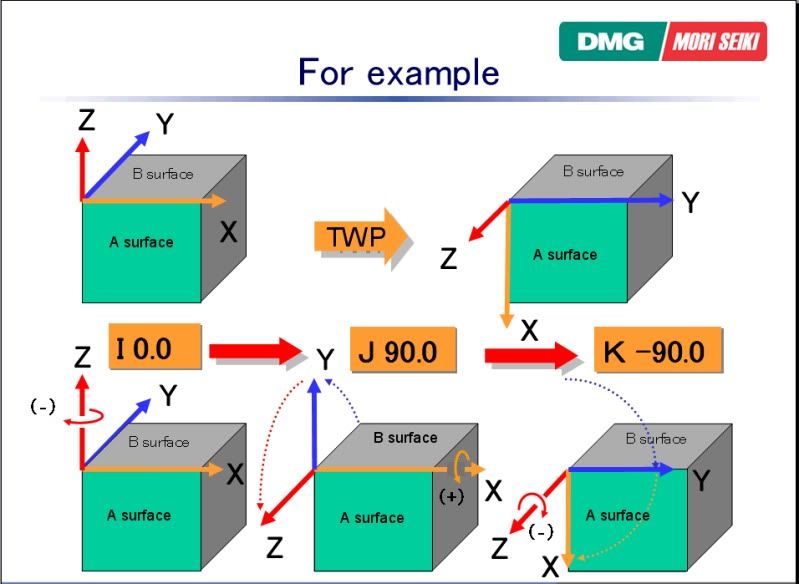

G68.2 X... Y... Z... I... J... K... R...

X, Y and Z define the center of rotation and will also be the work coordinate system origin.

I, J, K: Value is always 1 or 0. Only one address can be defined as 1 and the other 2 need to be 0. I1 means rotation around X. J1 means rotation around Y. K1 means rotation around Z.

R is the rotation angle. positive = CCW and negative = CW.

Hope this helps,

- Quote

Link to comment

Share on other sites

Newbeeee™

Posted December 17, 2010Newbeeee™

-

- Verified Members

-

- 3.6k

- Location:Where the Ind Revolution began

- Author

Thanks all,

I'll pass it on.

Cheers

- Quote

Link to comment

Share on other sites

Joe788

Posted December 17, 2010Joe788

-

- Verified Members

-

- 1.3k

- Location:California

Just curious, is there any real particular reason he wants/needs to use G68.2 on a trunnion machine?

- Quote

Link to comment

Share on other sites

Guest CNC Apps Guy 1

Posted December 17, 2010Guest CNC Apps Guy 1

-

- Guests

^^^

Maybe he's writing a program by hand (INSANE IMHO).

Just sayin... ![]()

Also, the function is called Tilted Working Plane.

I always thought I, J, K were the angles of pitch, roll, and yaw (or rotation around X, Y and Z respectively - See B-63944EN_03 pg 874,)

I didn;t know that right off the top of my head, but I was working with it this morning. ![]()

It's pretty involved to use it correctly. The pictures in the FANUC manual for a change actually are pretty decent and do help in understanding it... at least for me. Maybe my Jinglish is getting better.

- Quote

Link to comment

Share on other sites

MIL-TFP-41

Posted December 17, 2010MIL-TFP-41

-

- Verified Members

-

- 1.3k

- Location:Utah

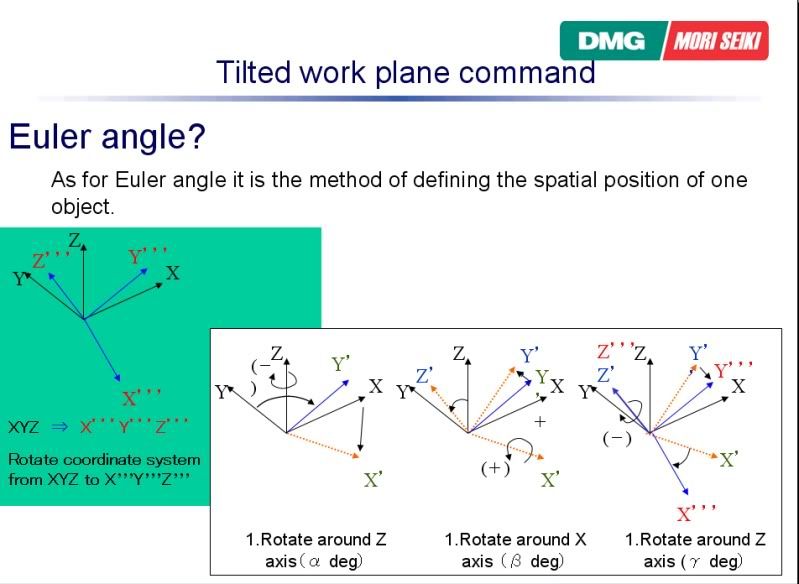

Basic explanation of TWP....wow. A couple of years ago I took an "advanced" class at Methods where they went through the theory of using G68.2 (Fanuc) and Cycle800 (Siemens)...they both work in a similar manner tho with the Siemens control you have about 5 different ways of using it....ugly words like Euler angles come to mind. A while ago I came across this site... http://bleiercnctrai...-machining.html . It is for the Siemens control but pretty much the same things apply for the Fanuc's.

Cycle800 does the transformation that calculates the orientation angles and actually commands the orientation axes to these angular positions. It also translates, rotates and translates again (if required) the G17 system so that when it is done the machine and control are ready to read-in and process G-code blocks that are identical to blocks for simple vertical bed mills.

- Quote

Link to comment

Share on other sites

Colin Gilchrist

Posted December 17, 2010Colin Gilchrist

-

- Verified Members

-

- 8.1k

- Location:Haht-fahd

OK, here it goes,

G68.2 X... Y... Z... I... J... K... R...

X, Y and Z define the center of rotation and will also be the work coordinate system origin.

I, J, K: Value is always 1 or 0. Only one address can be defined as 1 and the other 2 need to be 0. I1 means rotation around X. J1 means rotation around Y. K1 means rotation around Z.

R is the rotation angle. positive = CCW and negative = CW.

Hope this helps,

Martin,

This may be your particular Machine's implementation of G68.2, but many Fanuc controls will allow 3-dimensional rotation.

On these controls you will get a G68.2 X Y Z I J K (with no "R"). The I J K values will use Euler Angles for describing the Rotation about X,Y, and Z.

In these cases, I, J, and K will hold a rotation value from 0-90 degrees.

Most controls use G53.1 in conjunction with the G68.2 command. The G53.1 controls the Tool Axis direction (Z+ or Z- direction).

Wikipedia does a great job of explaining Euler's angles:

http://en.wikipedia.org/wiki/Euler_angles

- Quote

Link to comment

Share on other sites

Joe788

Posted December 17, 2010Joe788

-

- Verified Members

-

- 1.3k

- Location:California

Wikipedia does a great job of explaining Euler's angles:

http://en.wikipedia.org/wiki/Euler_angles

Good link Colin.

- Quote

Link to comment

Share on other sites

Colin Gilchrist

Posted December 17, 2010Colin Gilchrist

-

- Verified Members

-

- 8.1k

- Location:Haht-fahd

Thanks Joe.

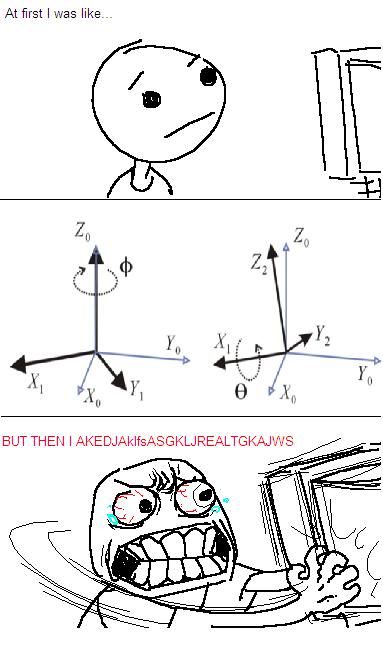

I get that way when I start reading the Geometric derivation section. My eyes start to roll back in my head...

In that section they talk about how to derive the Euler angles by using Matrix calculus.

- Quote

Link to comment

Share on other sites

Newbeeee™

Posted December 17, 2010Newbeeee™

-

- Verified Members

-

- 3.6k

- Location:Where the Ind Revolution began

- Author

Haha Joe!

Joe/James: - I *think* the G68.2 is what is spat out by the delcam post and he wanted to get his head around what it was doing.

Notice the word *think* here....![]()

- Quote

Link to comment

Share on other sites

MotorCityMinion

Posted December 18, 2010MotorCityMinion

-

- eMC Learning Group

-

- 1.3k

Had to save that pic.

- Quote

Link to comment

Share on other sites

Mick

Posted December 18, 2010Mick

-

- Verified Members

-

- 2.6k

- Location:Kicked in the corner

Out of curiosity, what is the difference between G68.1 and G68.2? We use G68.1 on our Mori Seiki MT's, and it is for the same reason, a tilted working plane. We cut keyways in tapered shafts, and it is a much cleaner method of programming. Ironically, most of our operators hate it, but I think that is because they dont understand it ![]()

- Quote

Link to comment

Share on other sites

Colin Gilchrist

Posted December 18, 2010Colin Gilchrist

-

- Verified Members

-

- 8.1k

- Location:Haht-fahd

I'll check my Fanuc manual later on the G68.1, but I remember that G68 with no decimal is Pinch Turning on a Lathe (at least according to my manual).

The whole point of using the transformed work plane command is that you can create a 'reference plane' that is rotated in 3D space, and program using standard 3 axis code. It is typically used to simplify 3+2 machining. Your controller will take the 3 axis code ( a pocket or canned tap cycle for example) and do the 5 axis motion calculations inside the control.

As others have mentioned, the Siemens CYCLE 800 is another example of using transformed work planes.

- Quote

Link to comment

Share on other sites

Mic

Posted December 18, 2010Mic

-

- Verified Members

-

- 278

- Location:Denmark

Well I've worked with both MAM72 and the new MX-520.

XYZ of the G68.2 line is new origin and centre of the rotation.

IJK is Euler rotation angles. I rotates around the untransformed Z axis, value can be +/- 180 ( or 0-359.999 depending on machine ) J is then rotation around the new X axis, here the value can be from 0 and up to endstop of A( B ) axis. Finally K is rotation around the new Z axis to allow the user to position the X axis in the wanted direction.

Always use G53.1 after the G68.2 line.

You'll also need to apply G43 after G53.1 and cancel it again ( G49 ) before G69

As already mentioned Siemens CYCLE800 can do exactly the same. And so will Heidenhain CYCL DEF 7 + CYCL DEF19 ( PLANE )

- Quote

Link to comment

Share on other sites

Joe788

Posted December 18, 2010Joe788

-

- Verified Members

-

- 1.3k

- Location:California

Well I've worked with both MAM72 and the new MX-520.

XYZ of the G68.2 line is new origin and centre of the rotation.

IJK is Euler rotation angles. I rotates around the untransformed Z axis, value can be +/- 180 ( or 0-359.999 depending on machine ) J is then rotation around the new X axis, here the value can be from 0 and up to endstop of A( B ) axis. Finally K is rotation around the new Z axis to allow the user to position the X axis in the wanted direction.

Always use G53.1 after the G68.2 line.

You'll also need to apply G43 after G53.1 and cancel it again ( G49 ) before G69

As already mentioned Siemens CYCLE800 can do exactly the same. And so will Heidenhain CYCL DEF 7 + CYCL DEF19 ( PLANE )

Mic, is there any particular reason you're using G68.2? I know why people use it on nutating head machines, but I haven't come across a need to use it on a trunnion machine. Are you using a right angle?

- Quote

Link to comment

Share on other sites

Dave.L

Posted December 18, 2010Dave.L

-

- Verified Members

-

- 1.3k

Joe, did you rob that pic from Evil? Or are you his protégé ? ![]()

- Quote

Link to comment

Share on other sites

Joe788

Posted December 18, 2010Joe788

-

- Verified Members

-

- 1.3k

- Location:California

Joe, did you rob that pic from Evil? Or are you his protégé ?

I robbed it randomly off of the web, and spliced in the Euler's angles part. If you do a google image search for "at first I was like", you'll find lots of hilarious stuff!

- Quote

Link to comment

Share on other sites

Mic

Posted December 18, 2010Mic

-

- Verified Members

-

- 278

- Location:Denmark

Mic, is there any particular reason you're using G68.2? I know why people use it on nutating head machines, but I haven't come across a need to use it on a trunnion machine. Are you using a right angle?

Yes there is. To be able to use the same program with different datum locations you either need to use G54.2(DFO) or G68.2(TWP). Dynamic Fixture Offset has one limitation. All machines I've seen has a small offset between A( B ) axis and C axis centre line measured in the XY plane, normally below 20 micron's. This small offset isn't compensated by G54.2 while G68.2 also takes care about this.

Maybe it's possible to compensate this in the postprocessor, but I've found it easier to use G68.2 because this works with most cam systems and posts.

- Quote

Link to comment

Share on other sites

Joe788

Posted December 18, 2010Joe788

-

- Verified Members

-

- 1.3k

- Location:California

Yes there is. To be able to use the same program with different datum locations you either need to use G54.2(DFO) or G68.2(TWP). Dynamic Fixture Offset has one limitation. All machines I've seen has a small offset between A( B ) axis and C axis centre line measured in the XY plane, normally below 20 micron's. This small offset isn't compensated by G54.2 while G68.2 also takes care about this.

Maybe it's possible to compensate this in the postprocessor, but I've found it easier to use G68.2 because this works with most cam systems and posts.

Ahhhh I see. I've only used G54.2 on a Matrix control, and it comps for the tiny mismatch between A and C. I didn't realize there were machines that didn't. Good knowledge!

- Quote

Link to comment

Share on other sites

DavidB

Posted December 21, 2010DavidB

-

- Verified Members

-

- 4.2k

- Location:Melbourne, Australia

HTH

I J K is actually rotate around Z X and Z again as above.

-

1

1

- Quote

Link to comment

Share on other sites

- 2 years later...

Guest

Posted November 19, 2013Guest

-

- Guests

Is there any particular reason you're using G68.2?

If one wants to have their part program display in "Part Coordinates" this function is helpful.

I just did some exhaustive training yesterday with a customer on FANUC 5-Axis Functions WSEC, TWP and TCP and using them seperately and together. I'm fine tuning my PowerPoint presentation. We're probably going to be put together a class after the first of the year for customers.

- Quote

Link to comment

Share on other sites

crazy^millman

Posted November 19, 2013crazy^millman

-

- Verified Members

-

- 20.8k

- Location:Temecula, CA

Let me know when you are putting it on I would love to sit in on it.

- Quote

Link to comment

Share on other sites

Newbeeee™

Posted November 19, 2013Newbeeee™

-

- Verified Members

-

- 3.6k

- Location:Where the Ind Revolution began

- Author

If one wants to have their part program display in "Part Coordinates" this function is helpful.

I just did some exhaustive training yesterday with a customer on FANUC 5-Axis Functions WSEC, TWP and TCP and using them seperately and together. I'm fine tuning my PowerPoint presentation. We're probably going to be put together a class after the first of the year for customers.

James - print it off and put it in a yellow binder and sell it to fanuc as an addendum to their manuals. This would really help probably 99% of the world using their 5axis controls!

-

2

2

- Quote

Link to comment

Share on other sites

Guest

Posted November 19, 2013Guest

-

- Guests

LOL

Yeah, their stuff is defintely lacking in that area.

What somebody needs to do is write a "FANUC for Dummies" manual that just goes through each and every g-code and gives a plain no :bs: explantion of each function and what format it needs to follow. Probably not going to make anone a millionaire but would be a significant bit of income.

I'd do it but I have no time and I'm not a great writer. I'd be willing to help or be a technical source for an effort like that though.

- Quote

Link to comment

Share on other sites

- Prev

- 1

- 2

- 3

- Next

- Page 1 of 3

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Reply to this topic...

Reply to this topic... × Pasted as rich text. Paste as plain text instead

Only 75 emoji are allowed.

× Your link has been automatically embedded. Display as a link instead

× Your previous content has been restored. Clear editor

× You cannot paste images directly. Upload or insert images from URL.

- Insert image from URL

- Desktop

- Tablet

- Phone

- Submit Reply

-

Recently Browsing 0 members

- No registered users viewing this page.

- Replies 68

- Created 15 yr

- Last Reply Sep 12

Top Posters In This Topic

-

crazy^millman 7 posts

-

Newbeeee™ 6 posts

-

Joe788 5 posts

-

Colin Gilchrist 4 posts

Popular Days

-

Dec 17 2010

12 posts

-

Jun 4 2014

9 posts

-

Dec 18 2010

7 posts

-

Feb 6 2019

6 posts

Popular Posts

Alex Dales

September 12, 2025

I very recently created this demo video that allowed me to show the Euler rotation with G68.2 directly in Machsim. G68_2 Euler Rotation.mp4 G68.2 uses an intrinsic rotation, meaning that

Delcandoit

February 14, 2014

I looked at this topic last Saturday and it baked my noodle. I went home and read the Wikipedia link from Colin, watched many Khan Academy videos, reread the Wikipedia link from Colin, visited all oth

Newbeeee™

November 19, 2013

James - print it off and put it in a yellow binder and sell it to fanuc as an addendum to their manuals. This would really help probably 99% of the world using their 5axis controls!

Posted Images

- All Activity

- Home

- Forums

- Mastercam Forums

- Industrial Forum

- G68.2 *basic* explanation

Join us!

eMastercam - your online source for all things Mastercam.

Together, we are the strongest Mastercam community on the web with over 56,000 members, and our online store offers a wide selection of training materials for all applications and skill levels.

Useful Links

Contact Info

Subscribe to eMastercam News

Legal

Privacy Policy

Store Terms & Conditions

Forum Guidelines

Follow us

×- Existing user? Sign In

- Sign Up

-

Home

- Back

- Home

- About Us

- About Mastercam

- Blogs

- Contact Us

-

Forums

- Back

- Forums

- All Activity

- Forum Guidelines

- Search

-

Store

- Back

- Store

- Flash Sales!

- Product Overview

- eCourses

-

Posts

- Back

- Post Request

-

Downloads

- Back

- Downloads

- Free eBooks

- Free Book Samples

- Mastercam Demo Software

- Files Referenced In Books

- Create New...

Từ khóa » G68.2 Cnc

-

FANUC G68.2 - 5-Axis Tilted Work Planes - LinkedIn

-

FANUC G68.2 - 5-Axis Tilted Work Planes - YouTube

-

Manipulating G68 2 5 Axis Tilted Work Planes - YouTube

-

Tilted Work Plane Milling G68.2. Fanuc Robodrill | Practical Machinist

-

Solved: Understanding G68.2 - Autodesk Community - HSM

-

5-Axis…it Just Ain't That Scary (continued) - Hurco

-

Programming 5-Axis Transform Planes Using IJK UVW Vectors

-

FANUC 5 AXIS PROGRAMMING CODES - StudyLib

-

FANUC 30i-B And 30i-B Plus Series Controls - Mastercam

-

Fanuc Alarm PS645 TOO MANY G68.2 NESTING - Helman CNC

-

G68.2 And G68.3 Transform Plane - • View Topic

-

5 Axis Programming - CNC Zone

-

Fanuc G68.2 - Compost Wiki