High-Feed Mills • M370™ Series - Inserts • Medium • WOEJ-MM

Product Similar To :

Back To | Modify Similar To M370 • WOEJ-MM • WO0804..Inserts • Medium • WOEJ-MM

Material Number5520248

ISO Catalog IDWOEJ080412SRMMANSI Catalog IDWOEJ080412SRMM

M370 - WOEJ-MM - WO0804.. 5520248 - WIDIA

Open expanded view

Open expanded view

Generic representation List Price$26.66/eachDiscountYour PriceGet your price/eachIn StockThis item is no longer availableLonger DeliveryDetailsMaterial Pricing Group Contact our sales team to discover all of your pricing options Qty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement. Add To Cart Contact Sales Contact Sales This item is no longer available Contact Sales Create SolutionAdd to Solution Feeds & Speeds Similar Products Send to {{cadTool}}

Generic representation List Price$26.66/eachDiscountYour PriceGet your price/eachIn StockThis item is no longer availableLonger DeliveryDetailsMaterial Pricing Group Contact our sales team to discover all of your pricing options Qty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement. Add To Cart Contact Sales Contact Sales This item is no longer available Contact Sales Create SolutionAdd to Solution Feeds & Speeds Similar Products Send to {{cadTool}} - P Steel

- M Stainless Steel

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

Clicking 'Create Solution' will take you to our Solution Building Experience.Look for the feeds and speeds icon (speedometer) on the product added.

Don’t see the icon? Try adding an additional product to the Solution to get feeds and speeds.

Cancel Create Solution- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

MetricInch

MetricInch| Material Number | 5520248 |

| ISO Catalog ID | WOEJ080412SRMM |

| ANSI Catalog ID | WOEJ080412SRMM |

| Grade | WS30PM |

| Cutting Edges per Insert | 6 |

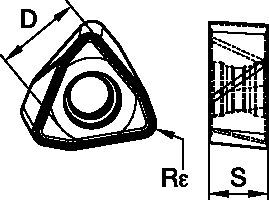

| [D] Insert IC Size | 7.8 mm |

| [D] Insert IC Size | 0.307 in |

| [S] Insert Thickness | 4.698 mm |

| [S] Insert Thickness | 0.185 in |

| [Rε] Corner Radius | 1.225 mm |

| [Rε] Corner Radius | 0.048 in |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

- Hardened Materials

Features and benefits

- -MM geometry provides lower cutting forces. First choice for steel, stainless steel, and high-temp alloys.

Create Solution to calculate Feeds and Speeds

Create SolutionAfter creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Light Machining | General Purpose | Heavy Machining |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5 % | 10 % | 20 % | 30 % | 40 100 % | ||||||||||||

| ..MM | 0,90 | 1,67 | 4,09 | 0,65 | 1,19 | 2,83 | 0,48 | 0,88 | 2,08 | 0,42 | 0,77 | 1,80 | 0,38 | 0,70 | 1,64 | ..MM |

| ..MH | 0,90 | 2,34 | 5,00 | 0,65 | 1,66 | 3,41 | 0,48 | 1,23 | 2,49 | 0,42 | 1,07 | 2,16 | 0,38 | 0,98 | 1,97 | ..MH |

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 100% | ||||||||||||

| ...MM | .035 | .061 | .150 | .025 | .044 | .104 | .019 | .033 | .076 | .017 | .028 | .066 | .015 | .026 | .061 | ...MM |

| ...MH | .035 | .092 | .197 | .025 | .065 | .134 | .019 | .048 | .098 | .017 | .042 | .085 | .015 | .038 | .078 | ...MH |

| Light Machining | General Purpose | Heavy Machining |

Speeds

| Material Group | TN6525 | TN6540 | WK15CM | WP25PM | WP35CM | WP40PM | WS30PM | WS40PM | WU35PM | |||||||||||||||||||

| P | 1 | 1340 | 1045 | 925 | 1180 | 925 | 785 | – | – | – | 1295 | 1120 | 1060 | 1790 | 1555 | 1460 | 1165 | 1025 | 965 | – | – | – | – | – | – | 850 | 750 | 705 |

| 2 | 1045 | 830 | 710 | 830 | 630 | 550 | – | – | – | 1080 | 940 | 785 | 1105 | 1000 | 905 | 985 | 845 | 710 | – | – | – | – | – | – | 720 | 620 | 520 | |

| 3 | 925 | 710 | 610 | 710 | 550 | 450 | – | – | – | 1000 | 845 | 690 | 1000 | 905 | 805 | 905 | 770 | 630 | – | – | – | – | – | – | 655 | 555 | 455 | |

| 4 | 770 | 550 | 475 | 590 | 430 | 355 | – | – | – | 890 | 725 | 590 | 750 | 690 | 630 | 805 | 670 | 535 | – | – | – | – | – | – | 590 | 490 | 390 | |

| 5 | 1025 | 770 | 650 | 785 | 590 | 490 | – | – | – | 725 | 670 | 590 | 1025 | 905 | 830 | 670 | 610 | 535 | – | – | – | 560 | 475 | 395 | 490 | 440 | 390 | |

| 6 | 670 | 535 | 430 | 535 | 395 | 335 | – | – | – | 650 | 490 | 395 | 630 | 535 | 430 | 590 | 450 | 355 | – | – | – | 490 | 360 | 260 | 425 | 325 | 260 | |

| M | 1 | 630 | 395 | 260 | 430 | 260 | 200 | – | – | – | 805 | 710 | 650 | 805 | 725 | 610 | 770 | 670 | 610 | 890 | 785 | 725 | 690 | 560 | 460 | 555 | 490 | 440 |

| 2 | 395 | 260 | 155 | 260 | 155 | 140 | – | – | – | 725 | 630 | 510 | 725 | 630 | 550 | 690 | 590 | 490 | 805 | 710 | 570 | 590 | 475 | 395 | 505 | 425 | 360 | |

| 3 | 415 | 260 | 180 | 275 | 155 | 140 | – | – | – | 550 | 475 | 370 | 570 | 510 | 450 | 510 | 450 | 355 | 610 | 535 | 415 | 475 | 360 | 280 | 375 | 325 | 260 | |

| K | 1 | 905 | 805 | 725 | 725 | 670 | 590 | 1655 | 1520 | 1340 | 905 | 805 | 725 | 1165 | 1045 | 940 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 710 | 630 | 590 | 570 | 510 | 450 | 1320 | 1165 | 1080 | 710 | 630 | 590 | 925 | 830 | 750 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 590 | 535 | 475 | 510 | 475 | 415 | 1105 | 985 | 905 | 590 | 535 | 475 | 770 | 690 | 630 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 155 | 120 | 95 | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 130 | 115 | 80 | 110 | 95 | 80 |

| 2 | – | – | – | 80 | 60 | 40 | – | – | – | 155 | 140 | 95 | – | – | – | 155 | 140 | 120 | 180 | 155 | 120 | 130 | 115 | 80 | 110 | 95 | 80 | |

| 3 | – | – | – | 235 | 140 | 95 | – | – | – | 200 | 155 | 95 | – | – | – | 200 | 155 | 120 | 215 | 180 | 120 | 165 | 130 | 80 | 145 | 110 | 80 | |

| 4 | – | – | – | 200 | 95 | 80 | – | – | – | 275 | 200 | 140 | 260 | 200 | 130 | 260 | 200 | 140 | 335 | 235 | 155 | 195 | 165 | 100 | 195 | 145 | 95 | |

| H | 1 | – | – | – | – | – | – | – | – | – | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Insert Selection

Insert Selection Guide

| Light Machining | General Purpose | Heavy Machining | ||||

| Material Group | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | ...MM | WP40PM | ...MM | WP40PM | ...MM | WP40PM |

| P3–P4 | ...MM | WP25PM | ...MM | WP40PM | ...MH | WP40PM |

| P5–P6 | ...MM | WP25PM | ...MH | WP25PM | ...MH | WP40PM |

| M1–M2 | ...MM | WP25PM | ...MM | WS30PM | ...MM | WP40PM |

| M3 | ...MM | WP25PM | ...MM | WP25PM | ...MM | WP40PM |

| K1–K2 | ...MH | WK15CM | ...MH | WK15CM | ...MH | WK15CM |

| K3 | ...MH | TN6520 | ...MH | TN6520 | ...MH | WK15CM |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ...MM | WP25PM | ...MM | WS30PM | ...MM | WP40PM |

| S3 | ...MM | WS30PM | ...MM | WS30PM | ...MM | WP40PM |

| S4 | ...MM | WS30PM | ...MM | WP40PM | ...MM | WP40PM |

| H1 | ...MH | WP25PM | – | – | – | – |

I have read and accepted the Terms & Conditions of use

Download Download CADCAD Drawings Models

Can’t find the file type you’re looking for?

Request DrawingsProduct data

SDS

Safety Data Sheets Create Solution to find the perfect compatible parts for your tool. Create Solution Product NameMaterial NumberISO Catalog IDANSI Catalog ID M370 • Shell Mills • WO08... • Metric4008276M370D050Z05WO08M370D050Z05WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Shell Mills • WO08... • Metric4008276M370D050Z05WO08M370D050Z05WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Shell Mills • WO08... • Metric4008277M370D066Z06WO08M370D066Z06WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Shell Mills • WO08... • Metric4008277M370D066Z06WO08M370D066Z06WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Cylindrical Shank • W008.. • Metric4008281M370D025Z02A25WO08L200M370D025Z02A25WO08L200List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Cylindrical Shank • W008.. • Metric4008281M370D025Z02A25WO08L200M370D025Z02A25WO08L200List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Cylindrical End Mills • iC08 • Medium • Inch4047654M370D100Z02C100WN08L600M370D100Z02C100WO08L600List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Cylindrical End Mills • iC08 • Medium • Inch4047654M370D100Z02C100WN08L600M370D100Z02C100WO08L600List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Cylindrical End Mills • iC08 • Medium • Inch4047655M370D100Z02C100WO08L800M370D100Z02C100WO08L800List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Cylindrical End Mills • iC08 • Medium • Inch4047655M370D100Z02C100WO08L800M370D100Z02C100WO08L800List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Cylindrical End Mills • iC08 • Medium • Inch4047656M370D100Z03C100WO08L600M370D100Z03C100WO08L600List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Cylindrical End Mills • iC08 • Medium • Inch4047656M370D100Z03C100WO08L600M370D100Z03C100WO08L600List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Cylindrical End Mills • iC08 • Medium • Inch4047657M370D125Z03C125WO08L600M370D125Z03C125WO08L600List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Cylindrical End Mills • iC08 • Medium • Inch4047657M370D125Z03C125WO08L600M370D125Z03C125WO08L600List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Cylindrical End Mills • iC08 • Medium • Inch4047658M370D125Z03C125WO08L800M370D125Z03C125WO08L800List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Cylindrical End Mills • iC08 • Medium • Inch4047658M370D125Z03C125WO08L800M370D125Z03C125WO08L800List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Shell Mills • iC08 • Medium • Inch4047660M370D150Z04S050WO08M370D150Z04S050WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart

M370 • Shell Mills • iC08 • Medium • Inch4047660M370D150Z04S050WO08M370D150Z04S050WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart  M370 • Shell Mills • iC08 • Medium • Inch4047661M370D200Z05S075WO08M370D200Z05S075WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart Load More You are about to add to your My Solutions page. Do you want to proceed? Cancel Continue Select the destination where you want to move to. Select the project where you want to add product(s) to. New Folder

M370 • Shell Mills • iC08 • Medium • Inch4047661M370D200Z05S075WO08M370D200Z05S075WO08List Price/eachDiscountYour PriceGet your price/eachQty Sold in pkg. of 0Adjusted to meet the minimum package size. Minimum qty: 0Adjusted to meet the minimum quantity requirement.In StockThis item is no longer availableLonger DeliveryDetails Add To Cart Load More You are about to add to your My Solutions page. Do you want to proceed? Cancel Continue Select the destination where you want to move to. Select the project where you want to add product(s) to. New Folder- Applied Filters:

- Clear All

A folder with the name already exists.

Special characters not allowed Cancel Create Product(s) successfully added to project __PROJECT_NAME__ Close Go to ProjectISO Catalog Number

ANSI Catalog Number

to find similar products. Solution CompatibilityReset Find Similar To ItemsThe following files are available

Please select a file to download

Models

I have read and accepted the Terms & Conditions of use

Download Download CADCan’t find the file type you’re looking for?

Request Drawings You should be logged to see your dashboard information Ok Session expired due to inactivity, please login againLogin The product/s () you were trying to add to the cart is/are not available, please contact customer service item(s) successfully added to the cart Cancel View Cart. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Search ShowAll ProductsSelected ProductsMinimum quantity should be

| SAP Material Number | ISO Catalog Number | Grade |

|---|

You are about to leave the Solution building process.

Are you sure you want to leave?

StayLeaveWorkpiece Selection- Standard

Standard

ALL

Material

Select a Value

Hardness

--

Hardness Scale

--

Permitted Groups :Group

SubGroup

Hardness (HB)

Hardness (HRC)

CancelOk Add without Reference Add with ReferenceTừ khóa » Chip M370

-

Intel® Core™ I3-370M Processor - Intel ARK

-

Intel® Core™ I3-370M Processor - 3M Cache, 2.40 GHz

-

Intel Core I3-370M @ 2.40GHz - Price Performance Comparison

-

AMD Radeon R7 M370 Specs - GPU Database - TechPowerUp

-

Impinj M700 Series RAIN RFID Tag Chips Extend IoT

-

Intel Core I3 370M Notebook Processor - Tech

-

Dell 4030 Chíp Core I3 M370 Ram 4G Hdd 250G

-

Chíp Intel Core I3 370M (3M Cache, 2.40 GHz) | Shopee Việt Nam

-

Dell 4030 Chíp Core I3 M370 Ram 4G Hdd 250G - Máy Tính Trần Anh

-

Compare LG Tri Chip C333 - Vs - Samsung M370 - Gadgets Now

-

High-Feed Mills • M370™ Series - Inserts • Medium • WOEJ-MH

-

Áo Thun, áo Phông Tay Lỡ Form Rộng Oversize Anime Hoạt Hình M370 ...

-

Z370M Pro4 - ASRock