Occupational Hygiene - Occupational Exposure Limits : OSH Answers

- Skip to main content

- Skip to site information

You are here: Occupational Hygiene - Occupational Exposure Limits

- Home

- OSH Answers Fact Sheets

- Health and Safety Programs

- Occupational Hygiene

- Occupational Hygiene - Occupational Exposure Limits

On this page

- What is occupational hygiene?

- What are the occupational exposure limits?

- Are there different types of exposure limits?

- What if I am exposed to several chemical substances at the same time?

- What if I work more than eight hours per day or 40 hours per week?

The occupational hygiene is the branch of occupational health and safety which focuses on the prevention of the occupational diseases. The exposure to health hazards can lead to diseases and illnesses that can manifest either immediately or after a long period of time after the exposure has stopped. Since these diseases are a consequence of exposure to hazards present in the workplace, they are known as occupational diseases. Occupational hygiene uses the techniques of anticipation, identification, evaluation, and control to identify and evaluate exposure.

The goal is to identify solutions for eliminating or reducing the hazard, and monitoring to ensure no further harm occurs. Occupational exposure limits are one tool or method used in this process.

In general, the occupational exposure limit (OEL) indicates the level of admissible exposure, for a length of time (usually 8 hours), to a chemical or physical hazard that is not likely to affect the health of a worker.

These limits are set out by many professional organizations around the world, such as the American Conference of Governmental Industrial Hygienists (ACGIH) and the National Institute for Occupational Safety and Health (NIOSH) in the United States.

The OELs for chemical substances are established based on the chemical properties of the substance, experimental studies on animals and humans, toxicological and epidemiological data. Different organizations may use different terminology for the OEL. For example, the ACGIH term for OEL is "Threshold Limit Value" (TLV)®, while the NIOSH term is "recommended exposure limits" (REL).

The OELs for physical hazards are based on industrial experience and experimental human and animal studies.

A list of legislative references for Exposure Limits to Chemical and Biological Agents for Canadian jurisdictions is available. Please note that while you can see the list of legislation for free, you will need a subscription to view the actual documentation.

Remember! A legal limit or guideline (such as an occupational exposure limit) should never be viewed as a line between "safe" and "unsafe". The best approach is to always keep exposures or the risk of a hazard as low as possible.

As an example, carcinogens do not usually have exposure limits. With many carcinogens, it is difficult to say for certain that if exposure is below a set point, the agent is not likely to cause harm. For this reason, for carcinogens and other specific agents (such as allergens), the "As Low as Reasonably Practicable" (ALARA) principle should be applied. ALARA, in practical terms, means that exposure should be eliminated or reduced as much as possible.

For chemical substances, ACGIH (2021) defines four categories of threshold limit values:

Threshold Limit Value – Time-Weighted Average (TLV-TWA): the time-weighted average concentration of a hazardous substance in the air averaged over an 8-hour workday and a 40-hour workweek to which it is believed that workers may be repeatedly exposed, day after day, for a working lifetime without adverse effects.

The time-weighted average concentration calculation considers the variations of the concentration in the air of a hazardous substance and the exposure time to that concentration over an 8-hour workday.

where

ti is the period of time the worker was exposed to the concentration ci.

Threshold Limit Value – Short-term exposure (TLV-STEL): a 15-minute time- weighted average exposure that should not be exceeded at any time during a workday, even if the overall 8-hour TLV-TWA is below the TLV-TWA. Workers should not be exposed more than four times per day to concentrations above TLV-TWA up to TLV-STEL. There should be at least a 60 minute interval between exposures. The short-term exposure threshold has been adopted to account for the acute effects of substances that have primarily chronic effects.

Threshold Limit Value – Ceiling (TLV-C): the concentration that should not be exceeded during any part of the working exposure.

Threshold Limit Value – Surface Limit (TLV-SL): the acceptable concentration of a substance on a surface that is not likely to result in adverse health effects if a person touches that surface. It supplements the airborne TLVs for substances for which the route of exposure is through the skin and those identified as skin and respiratory sensitizers.

Peak exposures should be always controlled. For substances that do not have TLV-STEL or TLV-C established, the maximum admissible peak concentrations may exceed three times the value of TLV-TWA for maximum 15 minutes, for a maximum of four occasions spaced at least one hour apart during a workday. The exposure should never exceed 5 times the TWA and the 8-hour TWA should not be exceeded for an 8-hour work period.

The units of measures for the TLV-TWAs, TLV-STEL and TLV-C are ppm and mg/m3. The TLVs for aerosols are usually expressed in mg/m3. The TLVs for gases and vapours are expressed in ppm or mg/m3.

The units of measure for TLV-SL is mg/100 cm2.

For physical hazards, ACGIH defines:

Threshold Limit Value – Time-Weighted Average (TLV-TWA)*: The time-weighted average exposure for an 8-hour workday and 40-hour workweek.

Threshold Limit Value-Ceiling (TLV-C)*: Exposure limit that should not be exceeded even instantaneously.

Adapted from: 2021TLVs® and BEIs® - Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices. Cincinnati: American Conference of Governmental Industrial Hygienists (ACGIH)

For more information about OELs for physical agents, visit our factsheets:

- Noise - Occupational Exposure Limits in Canada

- Ultraviolet Radiation

- Radiation - Quantities and Units of Ionizing Radiation

- Vibration - Measurement, Control and Standards

- Cold Environments - Working in the Cold

- Temperature Conditions - Hot

In the workplace, a worker may be exposed to several chemical substances at a time. If the toxicological effect of the substances is similar (e.g., each substance affects the same target organ or has a similar effect), it can be considered that the combined effect of the chemicals will be the sum of individual effects. A common example is exposure to several organic solvents.

In this case, ACGIH recommends the following calculation:

If the sum of:

C1/T1 + C2/T2 +….Cn/Tn

is higher than 1, the threshold limit of the mixture is exceeded.

(C is the concentration in the air of the substance and T is the threshold limit)

This formula should not be used for:

- mixtures of substances with toxicological effects are not additive (individual toxicological effects and target organs are different),

- mixtures of substances which inhibit each other's effect,

- substances that may have a synergistic effect,

- carcinogens (exposure to mixtures of carcinogens should be eliminated or as low as possible), and

- complex mixtures (e.g., diesel exhaust).

The threshold limit values apply for 8-hour workday and 40-hour workweek. When working shifts longer than eight hours, the exposure time is increased and the recovery period between exposures is decreased. In these situations, the threshold exposure limit should be so adjusted that, in the end, the peak body burden does not exceed the one that would occur during a normal eight hour shift.

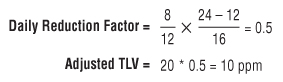

There are numerous mathematical models, some simple and some more complex, that can be used to adjust the TLV for chemical exposure to a different work schedule. ACGIH indicates that the Brief and Scala model is easier to use. This model reduces the TLV by a factor that considers the hours worked daily and the periods of rest between them. There are two reduction factors that can be used to calculate the adjusted TLV: one based on daily exposure, and one based on averaged weekly exposure.

Note: The daily reduction factor does not consider the number of days worked per week (e.g., where workers work 12-hour shifts, 5 days one week and 2 days the next week). The number of days worked in a week is factored in the weekly reduction factor (e.g., where a worker works 9 hours/day, seven days per week).

Both daily and weekly reduction factors should be calculated, and the most stringent result should be considered for use.

ACGIH recommends medical supervision during the initial use of the adjusted TLVs.

For example, the modified TLV-TWA for toluene (TLV-TWA = 20 ppm) for a 12-hr/day 14-day pattern shift (five workdays one week and two workdays the next week) will be:

(The reduction factor is calculated for the 12-hour workday regardless of how many days, 5 or 2, are worked during a week).

(The reduction factor is calculated for the 12-hour workday regardless of how many days, 5 or 2, are worked during a week).Where a worker works 9 hours/day, five days/week, the modified TLV-TWA for toluene may be:

The TLVadj = 16.65 ppm obtained using the daily adjustment formula should be considered as it is more protective.

One of the shortcomings of the Brief and Scala method is that the reduction factor for a certain amount of worked hours is identical for all chemicals regardless of their individual biological half-lives. This assumption may lead to an overestimation of the degree to which the limit should be lowered.

The formula is not applicable for:

- Work schedules with less than seven to eight hours per day or less than 40 hours per week.

- Work schedules that involve 24-hour continuous exposure (e.g., in submarines and space shuttles).

- Certain irritants.

- Fact sheet last revised: 2022-03-25

Disclaimer

Although every effort is made to ensure the accuracy, currency and completeness of the information, CCOHS does not guarantee, warrant, represent or undertake that the information provided is correct, accurate or current. CCOHS is not liable for any loss, claim, or demand arising directly or indirectly from any use or reliance upon the information.

OSH Answers Fact Sheets- Search All Fact Sheets

- Back to Occupational Hygiene

Related Fact Sheets

- Occupational Hygiene - Dermal Exposure

- Converting Occupational Exposure Limits from mg/m³ to ppm

- Occupational Hygiene - Occupational Disease

CCOHS Features

Need more help?

Contact our Safety InfoLine

905-572-2981.

Toll free 1-800-668-4284

(in Canada and the United States)

Ask a QuestionCCOHS Safe Work App

Have the answers at your fingertips. Download the CCOHS Safe Work app for free.

Related Content

Occupational Health and Safety Management Systems

Learn how to develop a health and safety management system.

View Course View All CoursesAdd page to saved links

-

- Return to Portal Add page to saved links

Success!

This page has been added as a saved link.

Error!

This page could not be added as a saved link. Please try again later.

Từ khóa » Em=(c1÷l1+c2÷l2)+. . .(cn÷ln)

-

[XLS] Equivalent Exposure Calculator

-

Calculating Permissible Exposure Limits (PELs) - Grainger KnowHow

-

[PDF] Toxic And Hazardous Substances, 1910.1000 -- Air Contaminants

-

[PDF] Chapter 6 SOLUTION OF VISCOUS-FLOW PROBLEMS

-

[PDF] One-way And Two-way Slabs

-

Spinal Anatomy | Vertebral Column - SpineUniverse

-

[PDF] Stata Longitudinal-Data/Panel-Data Reference Manual

-

[PDF] Legendrian Varieties - CiteSeerX