PUE H315 Indicator ›› Indicators And Terminals - Radwag

PUE H315 Weighing Terminal

✆ en search Português (Brasil)DeutschEnglishEspañolFrançaisItalianoJapanese (日本語)PolskiTürkiye Česky USA

en search Português (Brasil)DeutschEnglishEspañolFrançaisItalianoJapanese (日本語)PolskiTürkiye Česky USA Scan model

ProductsProductsCustomer SupportNewsCompanyDealer ZoneKnowledge BaseContactLaboratory BalancesIndustrial ScalesScales for Ex AreasMedical ScalesPGC ScalesCheckweighersMass ComparatorsFilter WeighingPipettes CalibrationPharma and Biotech SolutionsStent weighingMass StandardsWeighing TablesMetal DetectorsWeighing PlatformsWeighing ModulesWeighing TerminalsAccessoriesSoftware

ProductsProductsCustomer SupportNewsCompanyDealer ZoneKnowledge BaseContactLaboratory BalancesIndustrial ScalesScales for Ex AreasMedical ScalesPGC ScalesCheckweighersMass ComparatorsFilter WeighingPipettes CalibrationPharma and Biotech SolutionsStent weighingMass StandardsWeighing TablesMetal DetectorsWeighing PlatformsWeighing ModulesWeighing TerminalsAccessoriesSoftware  ProductsProductsCustomer SupportNewsCompanyDealer ZoneKnowledge BaseContactLaboratory BalancesIndustrial ScalesScales for Ex AreasMedical ScalesPGC ScalesCheckweighersMass ComparatorsFilter WeighingPipettes CalibrationPharma and Biotech SolutionsStent weighingMass StandardsWeighing TablesMetal DetectorsWeighing PlatformsWeighing ModulesWeighing TerminalsAccessoriesSoftware Show all products

ProductsProductsCustomer SupportNewsCompanyDealer ZoneKnowledge BaseContactLaboratory BalancesIndustrial ScalesScales for Ex AreasMedical ScalesPGC ScalesCheckweighersMass ComparatorsFilter WeighingPipettes CalibrationPharma and Biotech SolutionsStent weighingMass StandardsWeighing TablesMetal DetectorsWeighing PlatformsWeighing ModulesWeighing TerminalsAccessoriesSoftware Show all products CatalogsVideos

CatalogsVideos  New products

New products  Videos

Videos  Catalogs ‹‹ Products New products Company

Catalogs ‹‹ Products New products Company  Home > Products > Weighing Terminals > PUE H315 Weighing Terminal > PUE H315 Weighing Terminal

Home > Products > Weighing Terminals > PUE H315 Weighing Terminal > PUE H315 Weighing Terminal

PUE H315 Weighing Terminal

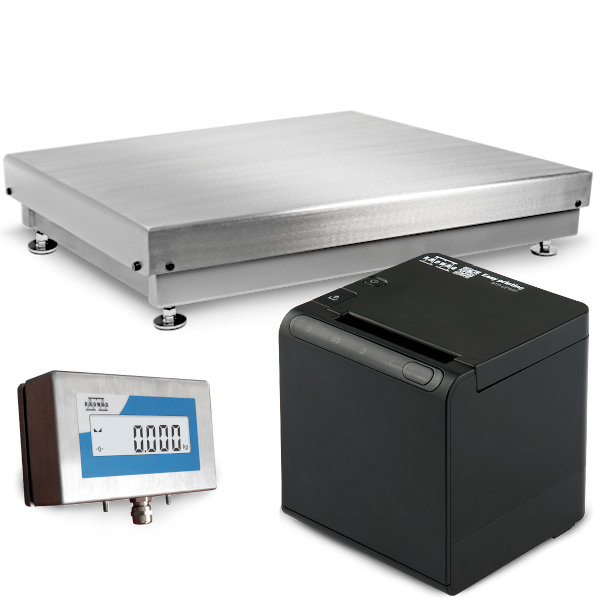

The terminal is intended to be a component of a vast range of industry scales – from small table-top scales, through platform, ramp, track and pallet scales, to livestock scales. It is equipped with a stainless steel housing of high ingress protection, IP 66/IP 67/IP 69. By standard the terminal features RS 232 and USB interfaces.

It has been with us for years, and will stay for a long time to come

The LCD display has accompanied us for long years. During this time it has proven its reliability. It guarantees the readability of the result from many angles and is energy efficient.Inner power

No access to mains power? Power failure? No problem. Thanks to its internal rechargeable battery, the H315 scale works anyway (up to 7 hours). Power supply is available at an extra charge. As standard, the scale is equipped with a RS232 cable, to which you can connect most of the accessories from our range.Not just weighing

The terminal has been equipped with numerous working modes: Parts Counting, +/- Control, Percent weighing, Totalizing, Peak Hold and Animal Weighing. Additionally, it enables defining of simple printouts in accordance with GLP procedures, and features weighing and ALIBI memory with export option, real time clock, and extensive tare functions.

Work as you like

A brand new design of the housing makes the terminal a compact device, which positively influences the comfort of operation. Another useful facility is the multifunctionally, this feature allows to operate the device when placed on a table or mounted to a post. In either case, tilt regulation is available. The said tilt regulation is also a convenience offered by a wall-mounting bracket. Besides, high ingress protection rate, which is the basic characteristic of the terminal, means failure free operation under harsh industrial conditions.

Communication Interfaces and Exchange of Information with External Devices

Possibility to furnish the terminal with additional interfaces, makes its adaptation to customer requirements easy. This facilitates especially communication with stack lights and external buttons controlling scale functions (zeroing, taring and printout), and integration with unsophisticated automation systems. The terminal allows for communication with external devices such as receipt printer, additional display, computer or USB flash drive. Datasheet| OIML Class | III |

| Maximum quantity of divisions from converter | 838 860 ×10 |

| Maximum quantity of verification units | 6000 e |

| Minimum volatge per verification unit | 0.4 µV |

| Maximum voltage per verification unit | 3.25 µV |

| Minimum load cell impedance | 50 Ω |

| Maximum load cell impedance | 1200 Ω |

| Load cell excitation voltage | 5V DC |

| Maximum increase of signal | 39 mV |

| Connection of load cells | 4 or 6 wires + shield |

| Display | 4.3” LCD (backlit) |

| Device dimensions W x D x H | 208×145×80 mm |

| Packaging dimensions W x D x H | 300×250×130 mm |

| Net weight | 1.9 kg |

| Gross weight | 2.2 kg |

| Protection class | IP 66 / 67 / 69 |

| Keypad | microswitch |

| Housing | Stainless steel |

| Communication interface | RS232, USB |

| Optional interfaces | RS232 or RS485 or 4IN/4OUT or Ethernet or analog output 4-20 mA |

| Power supply | 100 – 240 V AC 50/60 Hz |

| Optional power supply | internal rechargeable battery |

| Operation time on batteries | max 7h |

| Operating temperature | -10 – +40 °C |

| Storage temperature | -10 – +50 °C |

| Relative humidity | 10% – 80% RH no condensation |

| Number of buttons | 5 |

| Multiple range | 1 or 2 ranges |

| Additional LCD display | WD-4/1 (option) |

Videos Complete Solutions for Mass Measurement in Pharma Industry PUE H315 – Robust Weighing Terminal For the Toughest Industrial Applications Functions Plus/Minus Control

Videos Complete Solutions for Mass Measurement in Pharma Industry PUE H315 – Robust Weighing Terminal For the Toughest Industrial Applications Functions Plus/Minus Control Plus/Minus Control

Control of sample's mass carried out with reference to specified MIN and MAX thresholds. The weight is considered to be correct if it is comprised within threshold values. A graphic visualisation of weighing result is displayed in a form of a bar graph. Percent WeighingPercent Weighing

Percent Weighing function is used for comparision of measured products with mass standard. Mass of a mass standard may be a numeric value taken from a database or it may be determined through a measurement process. Each measured product is compared to mass standard, mass of which is presumed as a model 100% ideal mass. For products weighing less than the mass standard, obtained results are lower than 100%, for products weighing more, the obtained results are greatly exceeded. TotalizingTotalizing

Function adding new mass value to already obtained one. This allows to determine mass content of the mixture, being a composition of number of different consistence components. Totalizing is limited by maximum capacity parameter. Parts countingParts counting

Function using mass measurement for determination of measured items quantity. Mass of a single item is required for this process. It may be either estimated through weighment or taken from a database. For items counting the following algorithm is used: all items mass / single item mass = quantity. Function operation is supperted by a mechanism of Automatic Correction of Accuracy. This allows to update single item mass in course of the process. To a certain extend Automatic Correction of Accuracy eliminates error which may be a result of different mass values of seemingly alike single elements. For industry solutions items counting may be simultaneously carried out with checkweighing and dosing thus industry solutions feature audio signalling base informing that specified number of items has been weighed. It is possible to apply weighing systems using few platfroms of different MAX capacities and different accuracies. Internal batteryInternal battery

Internal and rechargeable battery of SLA 6 V type (sealed lead acid) enables device operation without connecting the device to the mains (9h operation). The weighing instrument controls battery status and displays a respective pictogram on the screen. Peak holdPeak hold

Function registering the greatest temporary indication occurring in course of the weighing process. It is most often used in medical scales in order to hold the measurement indication. GLP ProceduresGLP Procedures

Diagnostic function allowing to objectively document performed measurements. GLP procedures may be either presented in a short report form or extended one. Animal weighingAnimal weighing

Process of mass determination for a product which may unwillingly reposition within the weighing pan. Mass determination in such cases requires much longer period of time when compared to typical weighing process. It is the user who defines period of time needed for control of measured product mass. The user can thus optimize the function depending on the measured product characteristics. ALIBI MemoryALIBI Memory

"ALIBI" memory enables saving and storing up to 100000 measurements. Measurements are saved automatically upon each pressing of the key. There is no need for any additional operations or changing settings. The following data related with the measurements is saved: measurement date; measurement time; result (mass); tare value; operator carrying out the measurement (logged in); product name. The software saves the measurement in a so called loop, i.e. when the measurement no. 100001 is saved, the measurement 1 gets automatically deleted from the memory. Measurements saved to balance memory cannot be deleted. You can preview and print out the data saved to the ALIBI database. Documentation Datasheet Data Sheet

Data Sheet  User Manual - PUE H315

User Manual - PUE H315  Conformity Declarations

Conformity Declarations  H315 Indicator

H315 Indicator Từ khóa » H315

-

GHS Hazard Statements - Wikipedia

-

H315 - Wikidata

-

Hazard And Precautionary Statements - Sigma-Aldrich

-

H 315 - Adapter Sleeves For Metric Shafts - SKF

-

[PDF] H226 Flammable Liquid And Vapour. H315 H317 May Cause Skin ...

-

Hazardous Chemical Information System (HCIS) - Details

-

GHS Classification - PubChem

-

Part Number H315, Metric H Adapter Sleeve On The Timken Company

-

H315 - Creation Of A Datasheet As PDF - Medias

-

H315 SKF Adapter Sleeve 65mm Bore - Bearing King

-

H315 -SKF Adapter Sleeve - 65x75x98mm - Quality Bearings Online

-

Shaft Guide (Multiple Facet Type) - GBTT Series (GBTT80F2-H315)

-

Adapter Sleeves H3, Main Dimensions - DIN 5415, Taper 1:12 (H315)