What Is The AQL (Acceptance Quality Limit) In QC Inspections?

Có thể bạn quan tâm

Table of Contents

- What Does AQL Mean?

- Table of contents

- Getting familiar with the “AQL tables”, sometimes called “ANSI tables”

- Before using the AQL tables, you should know three parameters:

- 1. The ‘lot size’

- 2. Inspection level

- 3. The AQL limits

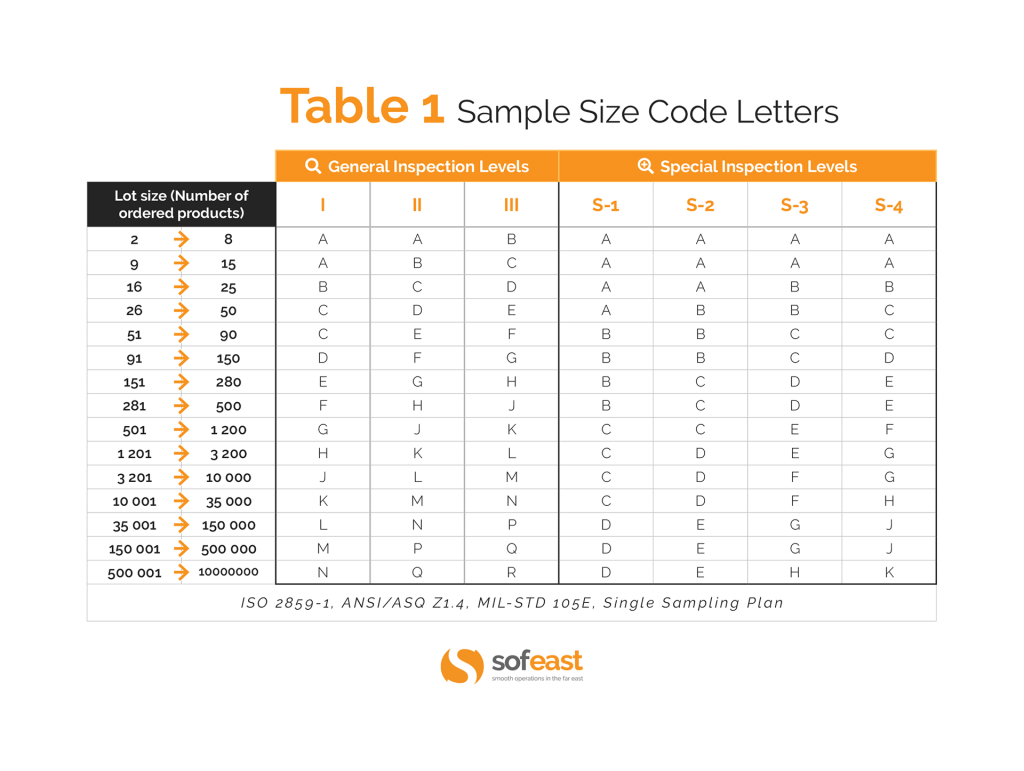

- First table: sample size code letters

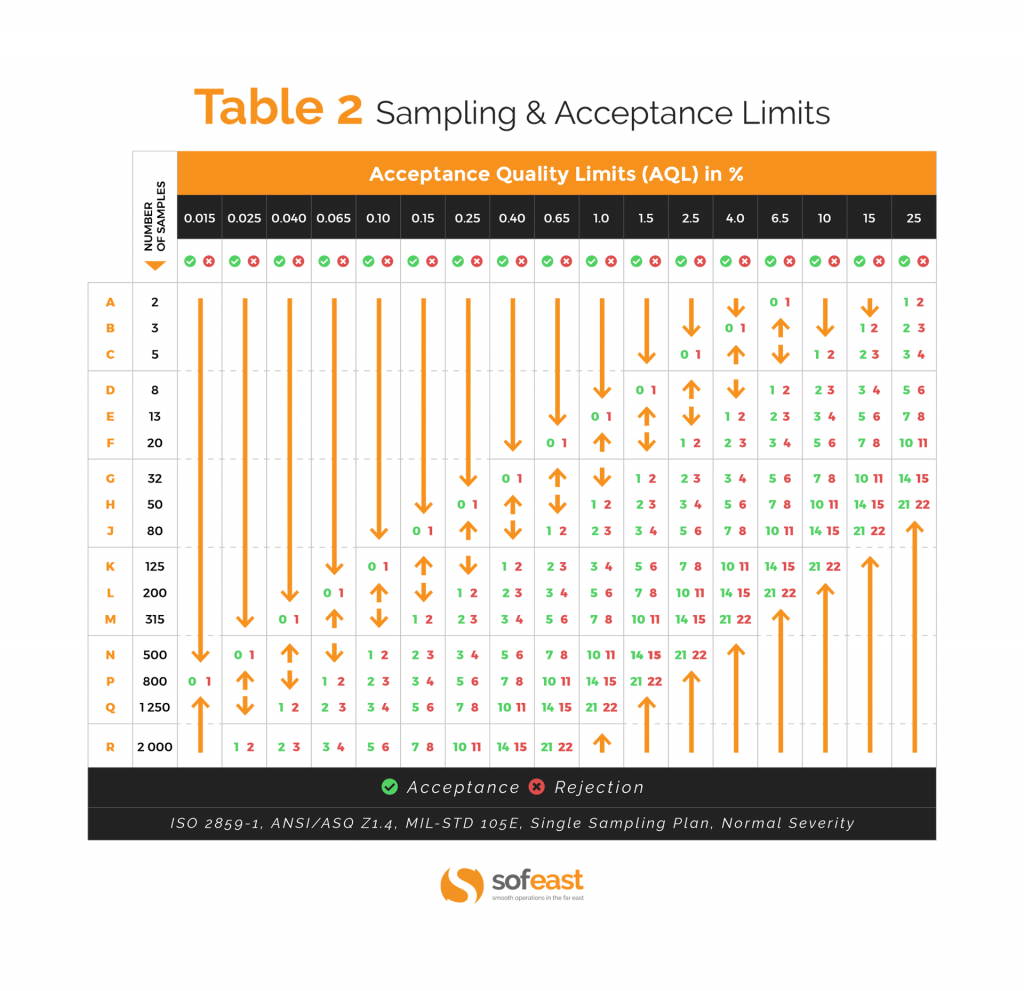

- Second table: single sampling plans for level II inspection (normal severity)

- AQL Calculator

- The need for an objective measurement of quality

- A look at AQL in more detail

- How To Read the AQL Tables for Quality Inspections (Random Sampling)

- Special case: the AQL in the Codex standard stan233 (food products)

- Frequently Asked Questions about AQL

- Questions about the general process of acceptance sampling

- So, basically, I have to authorize the factory to produce some defects?

- As a buyer, should I charge back the value of the defective products to the manufacturer?

- How to choose an AQL limit for my products?

- What are typical limits for consumer electronics?

- If I find too many defective samples, I have to reject the lot. However, what can I do to try and save the lot?

- What are the limits of a quality control approach based on random sampling and AQL limits?

- Can’t I just do my own sampling plan?

- Is there a more efficient way of checking the quality of finished products?

- Is the concept of “AQL” only this one sampling standard?

- What is the AQL standard? What is the AQL level? What is AQL sampling?

- Can we also use this sampling standard to check incoming goods (components)? Or is it only for finished products?

- We are setting different inspection levels for different parts of the inspection. When determining the acceptance of the entire lot, should we somehow combine it all to determine acceptance/rejection?

- Can we have the same AQL limits for all products, if they all go through the same distribution channel, same customers, same ‘promise’ to customers?

- Quality inspections based on acceptance sampling have been used for around 100 years. Is it still a valid approach?

- What did w. Edwards Deming, the famous statistician and “quality guru”, think about acceptance sampling in general?

- Questions about the way the underlying statistics work

- Why not just say, ‘we’ll check 10% of the quantity’, or whatever percentage deemed appropriate?

- Do we have to follow levels I, II, III, etc. and AQLs 1.0, 1.5, 2.5, etc.?

- How to calculate AQL values?

- Based on my AQL, I calculated the proportion of defects authorized. Why don’t they correspond to the maximum number of defects authorized?

- What are the “reduced” and “tightened” severities?

- What is NOT defined in the standard, and is free to be applied in different ways?

- Special cases

- If I find 3 minor defects on the same sample, should it be counted as 1 major defect?

- What if we check the quality before the whole batch is completed?

- Questions about the general process of acceptance sampling

- Need help with inspecting your production?

What Does AQL Mean?

‘AQL‘ stands for ‘Acceptance Quality Limit‘, and is a method used by many businesses to check a random sample from the production batch of their products and confirm that the risk of bad quality is relatively low.

In ISO 2859-1, the AQL is defined as the “quality level that is the worst tolerable.” It represents the maximum number of defective units, beyond which a batch is rejected. Importers usually set different AQLs for critical, major, and minor defects. Most Asian exporters are familiar with this type of setting.

For example: “AQL is 1.5%” means “I want no more than 1.5% defective items in the whole order quantity, on average over several production runs with that supplier, and I accept a certain amount of risk that I make the wrong decision based on the imperfect information coming from checking only a sample of the whole batch”.

Table of contents

Use these links to jump to the different sections of this article:

- What are the AQL Tables? (including video explainer)

- Convenient AQL calculator

- A more detailed look into the AQL

- Special case: the AQL in the Codex standard stan233 (food products)

- FAQs

Getting familiar with the “AQL tables”, sometimes called “ANSI tables”

The “AQL tables” are statistical tools at the disposal of buyinspection levelers (for product inspections). They are an industry standard. Most suppliers involved in international trade are familiar with it.

They help determine two key elements:

- How many samples should be picked and inspected, among a batch of product or parts?

- Where is the limit between acceptability and refusal, when it comes to defective products?

This video will help you become familiar with how the AQL tables work and are used:

(Note: you can watch this on Youtube and go straight to an example here.)

(Note: you can watch this on Youtube and go straight to an example here.)

Before using the AQL tables, you should know three parameters:

1. The ‘lot size’

If you ordered different products, consider each product as a separate lot. (The quantity of each product is the lot size). If you ordered only one product, the lot size is the total batch quantity.

2. Inspection level

Different inspection levels will command different numbers of samples to inspect. In this article, we will stick to the so-called “level II” under “normal severity” and to single sampling plans.

3. The AQL limits

The AQL limits appropriate for your market. If your customers accept very few defects, you might want to set a lower AQL for both major and minor defects.

Some specialized quality inspection software will show all the numbers automatically, but it is good to understand how to read the tables.

There are basically two tables. The first one tells you which ‘code letter’ to use. Then, the code letter will give you the sample size and the maximum number of defects that can be accepted.

First table: sample size code letters

Second table: single sampling plans for level II inspection (normal severity)

Note: in quality inspections, the number of defective products is only one of the criteria. It is sometimes called “quality”, or “quality findings”. The other criteria are usually on the inspector’s checklist, which typically includes:

- Packaging conformity (barcodes, inner packing, cartons, shipping marks…).

- Product conformity (aspect, workmanship…). If all the products are in red color instead of orange, there is no need to count each sample as a defect. It makes more sense to refuse for product conformity.

- Specific tests defined in the inspection checklist (they might not be performed on all inspected samples if they are time-consuming or destructive).

AQL Calculator

We usually help our clients to select the most suitable inspection levels and AQL limits, but you can use our calculator below (based on the AQL tables) to get a fast answer.

Fill in the calculator to easily find your perfect sample size (the number of pieces that should be randomly checked from the lot being examined) and the number of major and minor defects that can be tolerated based on your AQL specifications.

(This is based on the ISO 2859-1 standard, normal severity, single sampling plans only.)

The need for an objective measurement of quality

In certain product categories, there will be defective products in virtually every production batch. It is often true even after the manufacturer has checked each individual product and has repaired the defective ones since the visual inspection is not 100% reliable.

Therefore, in many supplier/buyer relationships (particularly when the application does not result in life or death outcomes), the supplier is not expected to deliver defect-free goods. The buyer needs to control the quality of purchased goods since he does not want too many defects. But what does “too many” mean?

How to set the limit between acceptability and refusal in a way that can be agreed upon and measured? This is when the AQL comes into play.

A look at AQL in more detail

As I wrote above, the ‘AQL’ is the “quality level that is the worst tolerable” on average over a period covering a number of batches.

In practice, three types of defects are often distinguished. For most consumer goods, the limits are:

- 0% for critical defects (totally unacceptable: a user might get harmed, or regulations are not respected, or the economic impact is catastrophic).

- 2.5% for major defects (these products would usually not be considered acceptable by the end user, for example the product does not work as intended).

- 4.0% for minor defects (there is some departure from specifications, but it is a small inconvenience and most users would not mind it — they might not even detect it).

These proportions vary in function of the product and its market. Components used in building an airplane are subject to much lower AQL limits.

Note that this tool is used mostly during final outgoing inspections (when the products are ready to be shipped out), and sometimes during production (when the number of products is sufficient to have an idea of the batch’s average quality).

If you really want to understand the concept of the AQL, you should spend about 20 minutes (total) watching this video on Youtube. Don’t forget to like and share it, please.

How To Read the AQL Tables for Quality Inspections (Random Sampling)

Or check out this article on how to read the AQL tables.

Or check out this article on how to read the AQL tables.

Special case: the AQL in the Codex standard stan233 (food products)

There is another widely-used standard for food products. It calls for taking a much smaller sample (which makes sense since opening a food product’s packaging means destroying it).

The general approach is the same, from what I saw, with some differences (e.g. the tables are different depending on the net weight of a unit of product).

Frequently Asked Questions about AQL

Questions about the general process of acceptance sampling

So, basically, I have to authorize the factory to produce some defects?

In theory no. That’s why the AQL was renamed, from “acceptable quality level” to “acceptance quality limit”. It is a “limit” (and a loose one at that).

Here is what the ISO 2859 standard says:

“Although individual lots with quality as bad as the acceptance quality limit may be accepted with fairly high probability, the designation of an acceptance quality limit does not suggest that this is a desirable quality level. Sampling schemes […] are designed to encourage suppliers to have process averages consistently better than the AQL.”

Note that, in practice, using these statistics means you assume the factory cannot reasonably be expected to turn out 100% good quality.

Alternatively, you can choose an “acceptance on zero” plan. As soon as one defect is found, the inspection is failed. But you can impose this on suppliers only in situations where quality requirements are very high (in the auto industry, in aerospace…).

As a buyer, should I charge back the value of the defective products to the manufacturer?

This is not standard practice. The standard practice is actually to charge nothing back, as long as the inspection is passed.

However, as the buyer, make sure to add this provision in your contract with the supplier: if an inspection is failed, the supplier has to sort & rework the goods, and submit them to a new inspection (and the re-inspection costs are charged back to them).

How to choose an AQL limit for my products?

I explained it in details in this article. It depends on your distribution channel and your product’s end use. Note that your supplier might refuse AQL limits they estimate as too tight (i.e. too low).

What are typical limits for consumer electronics?

A small company that doesn’t have much money to invest in DFM and the NPI process, in general, will usually set the limits at 2.5 or 1.5 (for major defects) and 2.5 or 4.0 (for minor defects). This should be communicated from the start, as it may have a direct impact on cost.

A company that invests a million USD or more in developing a new product, and that works with a contract manufacturer to prepare for large production volumes, will usually set a limit on major defects at 0.6 or 1.0. (source)

If I find too many defective samples, I have to reject the lot. However, what can I do to try and save the lot?

You can switch to 100% inspection and discard rejects.

You can also have a manager (on the buyer’s side) take a business decision – is it actually acceptable, even though the ‘quality result’ is not good?

In any case, don’t change the rules of the game (checking more samples by applying level III, going into double sampling), just to your purpose. This is not good. And it will send the signal to the supplier that your rules are negotiable or flexible.

What are the limits of a quality control approach based on random sampling and AQL limits?

A: There are several limits:

1. An AQL limit is a target rather than a maximum. The buyer might have a nasty surprise when receiving a batch of products that “passed” the inspection. Read more in this article.

2. A statistical QC approach does nothing to reduce the defects in the first place. Read more in this article.

Can’t I just do my own sampling plan?

Sure. If you have a math background, you know that you’ll need to use a hypergeometric distribution (since samples are taken from the lot at random, are checked, and not put back into the lot until the end of the inspection). Specialized software like Minitab can help you a lot here.

If you want to avoid statistics altogether, your limits on the numbers of defects will not make much sense, but they might “feel” right intuitively and it might make you more comfortable… Just be aware of their shortcomings.

Make sure you get the supplier’s agreement on your plan. This might be the hardest thing to achieve!

Is there a more efficient way of checking the quality of finished products?

There are many ways of drawing samples and checking their quality. If you don’t mind a more dynamic inspection plan, where the number of samples to check can’t be predicted in advance, you might want to follow a multiple-sampling plan or even a sequential sampling plan. On average, for the same confidence in the decision, fewer samples will need to be checked.

Is the concept of “AQL” only this one sampling standard?

No. For example, it is also in the Codex standard stan233 (generally used for certain food products). It calls for taking a much smaller sample (which makes sense since opening a food product’s packaging means destroying it).

The general approach is the same, with some differences (e.g. the tables are different depending on the net weight of a unit of the product).

What is the AQL standard? What is the AQL level? What is AQL sampling?

When you hear one of these terms, it generally refers to the acceptance sampling standard detailed in the ISO 2859-1 standard. Scroll to the top of this page and you will see how it works.Can we also use this sampling standard to check incoming goods (components)? Or is it only for finished products?

You may use it for checking pretty much anything, as long as the individual samples can be classified as “OK” or “defective”. This standard is often used for checking batches of components or subassemblies. It can also be applied for verification of inventory accuracy, or invoices accuracy, and so on.We are setting different inspection levels for different parts of the inspection. When determining the acceptance of the entire lot, should we somehow combine it all to determine acceptance/rejection?

Let’s say you want to do basic visual checks, and functional tests, on inspection level II. And dimensional inspection (which takes more time) are done on level S-3. In principle, when it comes to counting defectives and getting to a pass/fail result, you should treat your inspection on level II as one inspection, and that on S-3 as a separate inspection. It may all ends up in the same report, of course. But the results should come out separately. Then, if you have a pass on what you check in level II, but a fail on what you checked in level S-3, the whole report would logically be failed.Can we have the same AQL limits for all products, if they all go through the same distribution channel, same customers, same ‘promise’ to customers?

No. I’ll assume you need to be a bit stricter than the 0 (critical), 2.5 (major), and 4.0 (minor) limits that many importers opt for. How much stricter should you be? Here is a plan that usually makes sense: Limits of 0 (critical), 1.5 (major), and 2.5 (minor) for the regularly produced batches of the same products if you have a good assurance that the underlying process is in control and the process & components are never changed. In other cases, you need to be stricter. Limits of 0 (critical), 1.0 (major), and 1.5 or 2.5 (minor) make more sense.Quality inspections based on acceptance sampling have been used for around 100 years. Is it still a valid approach?

Yes, in many cases it is still a valid approach, especially if the buyer has no (or little) information about the supplier’s process performance. Since the 1980s, there has been more focus on supplier management, process control, engagement and training of people, maintenance of equipment, and other ways to reduce the proportion of defects. It tends to work very well in a highly collaborative buyer-supplier relationship.What did w. Edwards Deming, the famous statistician and “quality guru”, think about acceptance sampling in general?

He clearly wrote, in his book “Out of the Crisis”, that it was not a great approach, and that he favored checking either 0 products or 100% of the products, depending on the cost of inspection and on the cost of accepting a defective product. However, his comments were written in the context of a company that aims are reducing the proportion of defects as close to zero as possible, typically a manufacturer that receives parts before processing them. He may not have written the same thing after looking at the realities many importers of consumer goods have to deal with.Questions about the way the underlying statistics work

Why not just say, ‘we’ll check 10% of the quantity’, or whatever percentage deemed appropriate?

This is discouraged, as clause 4.3.3 of the ISO 2859-10 standard explains:

Ad hoc sampling should not be used because it will lead to unknown risks that may be too high. Furthermore, there is no formal basis for either the acceptance or non-acceptance of the lot. Examples of ad hoc sampling include the sampling of a fixed percentage of a lot or a convenience sample taken at haphazard times.

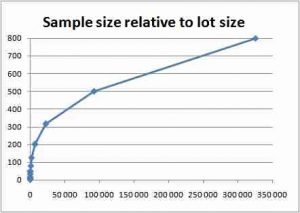

And here is one thing many buyers don’t realize. They say “inspect 10%”. But, as we go up in the total quantity, the proportion of products checked can decrease, for the same confidence in the inspection results.

As you can see in the chart below, if you follow the AQL tables, the number of samples to check (vertical axis) increases at a slower pace than the total quantity (horizontal axis).

Do we have to follow levels I, II, III, etc. and AQLs 1.0, 1.5, 2.5, etc.?

No. They are mere parameters that were thought to be applicable to most situations. For the sake of simplicity, it is better to have 3 tables with 10-20 columns each, than 50 tables with 100 columns each. Remember, all this was computed by hand in the 1930s, and inspectors had to look up the tables in paper form.

If you have a statistical software package such as Minitab, you can adjust the parameters as you see fit.

How to calculate AQL values?

If you have a statistical software package such as Minitab, you can re-do all the calculations and even adjust the parameters as you see fit. Some people have also done it in Excel.

If you deviate from the standard parameters, make sure your supplier confirms your new sampling plan & limits prior to any inspection work. You don’t want to get into a long justification after you reject a batch…

Based on my AQL, I calculated the proportion of defects authorized. Why don’t they correspond to the maximum number of defects authorized?

It is true. In our example above, 2.5% of 200 samples is 5 samples, but we accept the goods even if 10 samples are found with a major defect.

Why this difference? There are heavy statistics behind this issue. To keep it simple, the producer’s risk is his risk of rejection (based on the random element when drawing the sample) even though his products (if they were all checked) would be accepted. That risk is about 5% in this standard. And, along the same logic, there is a consumer’s risk and is around 10%. As you can see, this standard is favorable to the producer’s side.

What are the “reduced” and “tightened” severities?

They are designed to be used in very specific situations when a producer is particularly reliable, or on the contrary, fails too often.

In practice, these severities are seldom used. Most inspections are done in normal severity. The rules to switch from normal to reduced or tightened are considered an important part of the standard (actually the evolutions of these rules constituted the main changes from MIL-STD 105A and MIL-STD 105E) but can be ignored.

Jim Bossert wrote this in the Feb. 2016 issue of Quality Progress:

You can use any plan without using the switching rules, but you do run the risk of not meeting the alpha risk in the end. These plans were developed to be used, as documented.

A normal plan is generally used and the switching rules come in when the clearance number has been obtained.

Some processes may never switch. If you choose a plan that is tightened or reduced to start with, you potentially will either spend too much on inspection (tightened) or risk having a bad product go to the customer (reduced).

It is a business decision for you to make if your customer is not demanding it. The switching rules are there to protect the producer when the product is running well or it has problems.

What is NOT defined in the standard, and is free to be applied in different ways?

Several important things are not even mentioned in the ISO 2859-1 standard:

- How many cartons to pick (in case products are presented in master cartons, and the unit to check is the product). In most inspections, the number of cartons picked is the square root of the total number of cartons in the lot. Some companies request 2 times the square root.

- What the classes of defects should be. In most inspections, defective units can be classified as “critical”, “major”, or “minor”, and each company can define what is in what class. Some companies add extra classes: incidental, catastrophic, etc.

Special cases

If I find 3 minor defects on the same sample, should it be counted as 1 major defect?

The standard says nothing about this (or, more generally, about the way to count different classes of defects). So, this is up to your organization to decide.

One good way to think about it is, ‘is it a real problem if a consumer finds 3 minor defects on 1 product they bought?’ If the answer is “yes, definitely”, then count it all as 1 major defective unit.

What if we check the quality before the whole batch is completed?

A reader asked me about this special case. Production of 500,000 pieces is underway. An inspection is done when 10% of the production is ready. With a normal inspection level II, what is the sample size?

- 800 because total production is 500,000?

- 500 because pieces that are ready is only 50,000?

The short answer is, the standard doesn’t really address this special case, as it was primarily designed for an inspection after an entire batch has been made.

My practical answer is, go with this option:

- 500 because pieces that are ready is only 50,000

For further reading on this topic, feel free to check out all of my AQL posts and also read this detailed Quality Control basic concepts post here.

Need help with inspecting your production?

Get in touch with me by filling the form below and I will give you a tailored recommendation or quotation. My company Sofeast, can probably help you.

#af-form-532605733 .af-body .af-textWrap{width:98%;display:block;float:none;}#af-form-532605733 .af-body .privacyPolicy{color:#000000;font-size:11px;font-family:Verdana, sans-serif;}#af-form-532605733 .af-body a{color:#000000;text-decoration:underline;font-style:normal;font-weight:normal;}#af-form-532605733 .af-body input.text, #af-form-532605733 .af-body textarea{background-color:#FFFFFF;border-color:#000000;border-width:1px;border-style:solid;color:#000000;text-decoration:none;font-style:normal;font-weight:normal;font-size:12px;font-family:Verdana, sans-serif;}#af-form-532605733 .af-body input.text:focus, #af-form-532605733 .af-body textarea:focus{background-color:#FFFAD6;border-color:#5E5E5E;border-width:1px;border-style:solid;}#af-form-532605733 .af-body label.previewLabel{display:block;float:none;text-align:left;width:auto;color:#4D4D4D;text-decoration:none;font-style:normal;font-weight:bold;font-size:12px;font-family:Verdana, sans-serif;}#af-form-532605733 .af-body{padding-bottom:15px;padding-top:15px;background-repeat:no-repeat;background-position:inherit;background-image:none;color:#000000;font-size:11px;font-family:Verdana, sans-serif;}#af-form-532605733 .af-footer{padding-bottom:0px;padding-top:0px;padding-right:15px;padding-left:15px;background-color:#transparent;border-width:1px;border-bottom-style:none;border-left-style:none;border-right-style:none;border-top-style:none;color:#000000;font-size:12px;font-family:Verdana, sans-serif;}#af-form-532605733 .af-header{padding-bottom:9px;padding-top:9px;padding-right:10px;padding-left:10px;background-color:#F47B1F;background-repeat:no-repeat;background-position:inherit;background-image:none;border-width:1px;border-bottom-style:solid;border-left-style:none;border-right-style:none;border-top-style:none;color:#FFFFFF;font-size:16px;font-family:Verdana, sans-serif;}#af-form-532605733 .af-quirksMode .bodyText{padding-top:2px;padding-bottom:2px;}#af-form-532605733 .af-quirksMode{padding-right:15px;padding-left:15px;}#af-form-532605733 .af-standards .af-element{padding-right:15px;padding-left:15px;}#af-form-532605733 .bodyText p{margin:1em 0;}#af-form-532605733 .buttonContainer input.submit{background-image:none;background-color:#40ACEF;color:#FFFFFF;text-decoration:none;font-style:normal;font-weight:normal;font-size:14px;font-family:Verdana, sans-serif;}#af-form-532605733 .buttonContainer input.submit{width:auto;}#af-form-532605733 .buttonContainer{text-align:center;}#af-form-532605733 body,#af-form-532605733 dl,#af-form-532605733 dt,#af-form-532605733 dd,#af-form-532605733 h1,#af-form-532605733 h2,#af-form-532605733 h3,#af-form-532605733 h4,#af-form-532605733 h5,#af-form-532605733 h6,#af-form-532605733 pre,#af-form-532605733 code,#af-form-532605733 fieldset,#af-form-532605733 legend,#af-form-532605733 blockquote,#af-form-532605733 th,#af-form-532605733 td{float:none;color:inherit;position:static;margin:0;padding:0;}#af-form-532605733 button,#af-form-532605733 input,#af-form-532605733 submit,#af-form-532605733 textarea,#af-form-532605733 select,#af-form-532605733 label,#af-form-532605733 optgroup,#af-form-532605733 option{float:none;position:static;margin:0;}#af-form-532605733 div{margin:0;}#af-form-532605733 fieldset{border:0;}#af-form-532605733 form,#af-form-532605733 textarea,.af-form-wrapper,.af-form-close-button,#af-form-532605733 img{float:none;color:inherit;position:static;background-color:none;border:none;margin:0;padding:0;}#af-form-532605733 input,#af-form-532605733 button,#af-form-532605733 textarea,#af-form-532605733 select{font-size:100%;}#af-form-532605733 p{color:inherit;}#af-form-532605733 select,#af-form-532605733 label,#af-form-532605733 optgroup,#af-form-532605733 option{padding:0;}#af-form-532605733 table{border-collapse:collapse;border-spacing:0;}#af-form-532605733 ul,#af-form-532605733 ol{list-style-image:none;list-style-position:outside;list-style-type:disc;padding-left:40px;}#af-form-532605733,#af-form-532605733 .quirksMode{width:100%;max-width:540px;}#af-form-532605733.af-quirksMode{overflow-x:hidden;}#af-form-532605733{background-color:#FFFFFF;border-color:#8C8C8C;border-width:1px;border-style:none;}#af-form-532605733{display:block;}#af-form-532605733{overflow:hidden;}.af-body .af-textWrap textarea{width:100%;}.af-body .af-textWrap{text-align:left;}.af-body input.image{border:none!important;}.af-body input.submit,.af-body input.image,.af-form .af-element input.button{float:none!important;}.af-body input.submit{white-space:inherit;}.af-body input.text{width:100%;float:none;padding:2px!important;}.af-body textarea{padding:2px!important;}.af-body.af-standards input.submit{padding:4px 12px;}.af-clear{clear:both;}.af-element label{text-align:left;display:block;float:left;}.af-element{padding-bottom:5px;padding-top:5px;}.af-form-wrapper{text-indent:0;}.af-form{box-sizing:border-box;text-align:left;margin:auto;}.af-header,.af-footer{margin-bottom:0;margin-top:0;padding:10px;}.af-quirksMode .af-element{padding-left:0!important;padding-right:0!important;}.lastNameContainer{margin-top:10px;}.lbl-right .af-element label{text-align:right;}body {}#af-form-532605733 .bodyText p { margin: 0 0 1em !important;}

#af-form-532605733 .af-body { padding-top:}

#af-form-532605733 .af-body .af-textWrap { width: 100% !important;}

#af-form-532605733 .af-body .af-element { padding-top: 0px!important; padding-bottom: 0px!important;}#af-form-532605733 .af-body .af-element:first-child { margin-top: 0 !important;}#af-form-532605733 .af-body label.previewLabel { font-weight: 700 !important; margin-top: 0.25rem !important; margin-bottom: .25rem !important;}#af-form-532605733 .af-body input.text,#af-form-532605733 .af-body textarea { border-radius: 3px !important; box-sizing: border-box !important; color: #444444 !important; font-size: 1rem !important; margin-bottom: 0.75rem !important; padding: 8px 12px !important; -webkit-transition-duration: 0.3s; transition-duration: 0.3s;}

#af-form-532605733 .af-body select { width: 100%;}#af-form-532605733 .af-body .af-dateWrap select { width: 33%;}#af-form-532605733 .choiceList-radio-stacked { margin-bottom: 1rem !important; width: 100% !important;}#af-form-532605733 .af-element-radio { margin: 0 !important;}#af-form-532605733 .af-element-radio input.radio { display: inline; height: 0; opacity: 0; overflow: hidden; width: 0;}#af-form-532605733 .af-element-radio input.radio:checked ~ label { font-weight: 700 !important;}#af-form-532605733 .af-element-radio input.radio:focus ~ label { box-shadow: inset 0 0 0 2px rgba(25,35,70,.25);}#af-form-532605733 .af-element-radio input.radio:checked ~ label:before { background-color: #777777; border-color: #d6dee3;}#af-form-532605733 .af-element-radio label.choice { border: 1px solid #d6dee3; border-radius: 3px !important; display: block !important; font-weight: 300 !important; margin: 0.5rem 0 !important; padding: 1rem 1rem 1rem 2rem !important; position: relative; -webkit-transition-duration: 0.3s; transition-duration: 0.3s;}#af-form-532605733 .af-element-radio label.choice:before { background-color: #FFF; border: 1px solid #d6dee3; border-radius: 50%; content: ”; height: 0.75rem; margin-left: -1.3rem; position: absolute; -webkit-transition-duration: 0.3s; transition-duration: 0.3s; width: 0.75rem;}#af-form-532605733 .buttonContainer { box-sizing: border-box !important;}#af-form-532605733 .af-footer { box-sizing: border-box !important;}

#af-form-532605733 .af-footer p { margin: 0 !important;}#af-form-532605733 input.submit,#af-form-532605733 #webFormSubmitButton { border: none; border-radius: 3px !important; font-weight: bold; margin-top: 0.5rem !important; margin-bottom: 1rem !Important; padding: 0.6rem 1.5rem !important; -webkit-transition-duration: 0.3s; transition-duration: 0.3s; }#af-form-532605733 input.submit:hover,#af-form-532605733 #webFormSubmitButton:hover { cursor: pointer; opacity: 0.8;}

#af-form-532605733 input.text:hover { cursor: pointer; opacity: 0.8;}

.poweredBy a,.privacyPolicy p { color: #000000 !important; font-size: 0.65rem !important;}

Get in touch with us by filling this form and we’ll contact you by email as soon as possible!

First Name:

Last Name:

Email:

Add your message:

Tell us more about how we can help you here, please.We respect your email privacy

By completing this form you consent to receive a response to your query & QualityInspection.org’s great email newsletter so you won’t miss any of our posts. Your data will be stored securely and not shared with third-parties. If you would like to manage your subscriptions, please feel free to do so in any further emails.

// Special handling for in-app browsers that don’t always support new windows (function() { function browserSupportsNewWindows(userAgent) { var rules = [ ‘FBIOS’, ‘Twitter for iPhone’, ‘WebView’, ‘(iPhone|iPod|iPad)(?!.*Safari\/)’, ‘Android.*(wv|\.0\.0\.0)’ ]; var pattern = new RegExp(‘(‘ + rules.join(‘|’) + ‘)’, ‘ig’); return !pattern.test(userAgent); }

if (!browserSupportsNewWindows(navigator.userAgent || navigator.vendor || window.opera)) { document.getElementById(‘af-form-532605733’).parentElement.removeAttribute(‘target’); } })();

Get expert help to improve YOUR product quality from suppliers in China or Vietnam. Read: Quality Assurance In China Or Vietnam For Beginners

Grab your free copy of Sofeast’s eBook and learn the common traps new importers from China or Vietnam fall into, and how to avoid or overcome them in order to get the best possible production results. It also outlines a proven quality assurance strategy that you can follow in order to have better control over your product quality, covering:

- Finding Suitable Suppliers

- Defining your Requirements before Production Starts

- Don’t Skip the New Product Introduction Process

- Regular Quality Inspections (Trust but Verify)

- Tying Payments to Quality Approvals

Sounds good? Hit the button below to get your copy now:

*Editor’s note: This post was originally published in 2011, and has since been updated to include new information and formatting.

Từ khóa » Bảng Aql 0.4

-

Biểu đồ Chất Lượng AQL Chấp Nhận Trong Công Nghiệp Dệt May Thời ...

-

[AQL Là Gì?] Acceptable Quality Level - Bạn Cần Biết Gì Về Nó?

-

Tiêu Chuẩn AQL Trong Quản Lý Chất Lượng - ITG Technology

-

MẪU AQL TRONG GIÁM ĐỊNH CHẤT LƯỢNG - HQTS

-

Đi Tìm Hiểu AQL Là Gì Và Những Vấn đề Có Liên Quan Thú Vị

-

AQL Chart Trong Dệt May Và Sản Phẩm Tiêu Dùng

-

Acceptable Quality Limit - Sampling Table | AQL Standard - QIMA

-

Mức độ Chất Lượng Chấp Nhận được (Acceptable Quality Level

-

Aql Là Gì? Những Thông Tin Bạn Cần Nắm Rõ Về Thuật Ngữ Này

-

AQL Training Kiểm Tra Chất Lượng Theo Tiêu Chuẩn AQL - Tài Liệu Text

-

Acceptable Quality Level (AQL) Là Gì? - Sổ Tay Doanh Trí

-

[PDF] AQL CHART - InTouch Quality