Zund 3XL-3200 Manuals - ManualsLib

- Manuals

- Brands

- Zund Manuals

- Cutter

- 3XL-3200

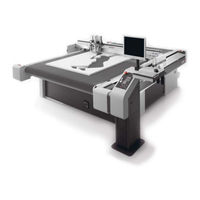

Zund 3XL-3200 Operating Manual (255 pages)

Digital flatbed cutter G3 series Brand: Zund | Category: Cutter | Size: 8 MBTable of Contents

- Contents 3

- Symbols 11

- Standards 13

- UL Testing 14

- Product Description 17

- Directional Information 17

- Product Identification 18

- Rating Plate 18

- UL Marking 19

- Intended Use 19

- Cutter - Overview 20

- Modules, Tools 21

- Tools for the um 22

- Rm-A 23

- Pum 23

- Mam-S/D 24

- Material Handling, Options 25

- Laser Pointer 25

- ICC Camera 25

- Cutter with Static Work Surface 25

- Cutter with Conveyor 26

- Sheet Feeder Options 26

- Drip Tray 27

- Technical Description 28

- Complete Machine 28

- Schedule of Work Sequences 28

- Table/Vacuum Plate 29

- Electronics Unit 29

- Power Unit 29

- Movement System 30

- Processing Materials 31

- Technical Information 32

- Dimensions and Weights 32

- Basic Device 32

- Cutter Extension 34

- Electrical Connection, Power Consumption 35

- Environmental Conditions 35

- Basic Device Compressed Air 35

- Control Unit 36

- Performance 37

- Emissions 38

- Safety 39

- Proper Use 40

- Hazard Warnings, Important Instructions 41

- Structure of the Hazard Warnings 42

- Areas of Responsibility 43

- Personnel Requirements 43

- Rules and Safety at Work 44

- Procedure in Case of Malfunctions 44

- Danger Areas 45

- Danger Area on the Module Carriage 46

- Danger Area During the Installation 47

- Working and Traffic Area 48

- Safety Signs 49

- Responsibility of the Operator 49

- Position of the Safety Signs 49

- Meaning of Safety Signs 50

- Prohibition Signs 50

- Order Signs 50

- Fire Protection Signs 50

- Safety and Monitoring Devices 52

- Protective System 53

- Operating Unit 53

- Emergency Stop Switch 54

- Safety Cut-Off Feature 54

- Personal Protective Equipment, Clothing 55

- Mechanical Hazards 56

- Gathering, Retraction 56

- Gathering, Impacts of Foreign Objects 56

- Cuts and Stab Wounds 57

- Risk of Burns 57

- Electrical Hazard 58

- Risks Arising from the Emission of Toxic Dust 59

- Environmental Hazard 60

- Handling and Storage of Chemicals 61

- Risk of Fire and Explosion 62

- Danger Caused by Laser Beam (Laser Pointer) 63

- Safety Instructions for Operators 63

- Safety Precautions for Service Personnel 64

- Disposal 64

- Controls and Operation 65

- Safe Working Practices 65

- Controls 66

- Control Panel 66

- Navigation Keys 68

- Numerical Keys 68

- Function Keys 68

- Travel Keys 69

- Soft Keys 69

- Special Keys, Shortcuts 70

- Emergency Stop Switches 71

- Maintenance Unit 73

- Interfaces 74

- Menu Navigation 75

- Menus and Functions 75

- Graphic Layout 75

- Direct Selection of Menus 75

- Value/Entry 76

- Default Settings (Factory Setting) 76

- Min/Max Settings (Factory Setting) 76

- Info Menu 77

- Popups/Dialogues 77

- User Level 78

- Allocate Function Keys Directly 79

- Allocating the Function Key Via the Menu 79

- Resetting a Function Key to the Factory Setting 79

- Set Language 80

- Set Display 80

- Setting the Volume of the Signal 80

- Delete Data Buffer 80

- Operation 81

- Daily Checks Prior to Start-Up 81

- Start-Up 82

- Switching on the Machine 82

- Initialising the Machine 83

- Operating Status 84

- Offline 85

- Stopped 85

- Online 86

- Moving the Bar/Module Manually 87

- Handling Modules/Tools 88

- Module/Tool/Tool Insert 89

- Set Module/Tool Change Position 90

- Inserting/Replacing the Module 91

- Module Mount 91

- Activating a Module 93

- Tool Handling 94

- Marking the Tool 94

- Switching the Tool Manager On/Off 94

- Tool Manager — Change Tool (um Module) 95

- Attaching/Selecting a Tool 96

- Creating a New Tool 96

- Selecting a Tool 96

- Deleting a Tool 96

- Inserting and Connecting a Tool (E.g. Oscillating Tool) 97

- Connecting Driven Tools - Allocating Port 99

- Connection - Electrical Tools (EOT, DRT, Etc.) 99

- Connection - Pneumatic Tools 100

- Tool Positions 101

- Material Hold-Down 102

- Defining/Checking the Vacuum Range 104

- Setting the Strength 105

- Switching On/Off 105

- Working with Air-Permeable Materials 105

- Checking the Range 105

- Feeding Options 106

- Feeding Clamps 107

- Setting the Feeding Clamps 107

- Activating/Deactivating Feeding Clamps 107

- Feed Guide Rail 108

- Assembling the Feed Guide Rail 108

- Automatic Feed 109

- Manual Feed 109

- Automatic Tool Initialisation (AKI) 110

- Adjusting the Height 111

- Laser Pointer, Reference Point 113

- Laser Pointer Settings 113

- Reference Point Settings 114

- Choose Laser Pointer as Pointer Type 115

- Define Reference Point 115

- Material Stop 116

- Module Carriage Slot Protective Plate 117

- Module and Tool Holder 118

- Switch off the Machine 119

- Description of Menu 121

- Menu Structure 121

- Continuous Path 127

- Raise if Overcurrent 127

- Stop Angle 127

- Speed Signal 128

- Speed Settings 128

- Up X&Y 128

- Down X&Y 128

- Accel. Settings 129

- Down Z Pos 129

- Max Z down 129

- Pos / Pressure Mode 129

- X&Y Pressure 130

- Auto Init Options 130

- Auto Lift-Up Angle 131

- T Axis Rotation 131

- Correct y 134

- Correct X 135

- Change Module/Tool 139

- Pointer Type 139

- White Balance 140

- Manual Move Settings 140

- Module Change Pos 140

- Position 140

- Park Options 142

- Light Barrier Options 143

- Acceleration Settings 144

- Feeding Mode 144

- Transport to the Front 146

- Transport to the Back 146

- Lower Feed Clamps 146

- Active Zones 150

- User Settings 159

- Troubleshooting 167

- Error Messages 170

- Cleaning and Maintenance 205

- Safe Maintenance of the Machine 206

- Operating Resources 207

- Handling Operating Materials 207

- Environmental Protection 207

- Cleaning Fluids 208

- Lubricants 208

- Adhesives 208

- Steps for Maintenance 209

- Lubrication Diagram 212

- Accessories Case 212

- Maintenance Jobs 214

- Service Flaps and Covers 214

- Maintenance Position 215

- Visually Inspect the Machine for Damage 215

- Clean the Machine 216

- Clean X Axis Guide Rails 217

- Cleaning the Guide Rails 218

- Oil X Axis Guide Bearings 219

- Guide Bearings 220

- Lubricating the Lubrication Points 221

- Cleaning/Oiling y Axis Guide Rails 223

- Lubricating the y Axis Bearing 225

- Clean the Chipping Protection Brush 226

- Cleaning the Feeding Clamps/Feed Guide Rail 227

- Draining the Maintenance Unit Condensation Water 228

- Automatic Circuit Breakers 229

- Conveyor Belt 231

- Removing the Conveyor Belt 231

- Removing the Covers 232

- Fitting a Conveyor Belt 233

- Tensioning the Conveyor Belt 239

- Instructions for Disposal 240

- Starting up after Periods at a Standstill 240

- Vacuum Generator 1-9 KW/1-15 KW 240

- Tools 241

- Modules 243

- Options 245

- Glossary 253

Related Products

- Zund 3XL-1600

- Zund 2XL-1600

- Zund 2XL-3200

- Zund L-2500

- Zund L-3200

- Zund M-1600

- Zund M-2500

- Zund XL-1600

- Zund XL-3200

Zund Categories

Cutter More Zund ManualsLogin

Sign In OR Sign in with Facebook Sign in with Google Don't have an account? Sign up! Restore passwordUpload manual

Upload from disk Upload from URL Thank you for your help!Từ khóa » G3 Xl-3200

-

G3 Digital Cutter - Zünd Systemtechnik AG

-

[PDF] Technical Data G3 Digital Cutter - Zünd Systemtechnik AG

-

ZUND G3 XL-3200, Re-Board Cutting - YouTube

-

[PDF] Quotation Zünd High Performance Cutter G3 XL3200

-

Zund G3 XL-3200 Automated Cutting Machine - Exapro

-

ZUND G3 XL 3200 Flatbed Cutter - SSE Worldwide

-

G3 XL-3200 - Premium - Conveyor Belt - With Full Front And Full Rear C

-

Zünd G3 XL-3200 Cutting System Improves And Accelerates BG ...

-

Conveyor Belt Zund G3 XL-3200+2XL-CE1600, 3923022 Type OR ...

-

Lot Zund G3 XL-3200 Digital Cutter

-

Lot Zund G3 XL-3200 Digital Cutter

-

Conveyor Belt Zund G3 XL-3200+2XL-CE3500, Type SU-P3 20630 X ...

-

Further, Higher And Faster For Victor VVV With The Zünd G3 XL-3200 ...