Basic Thread Concepts | Park Tool

Maybe your like

Intro to Threads

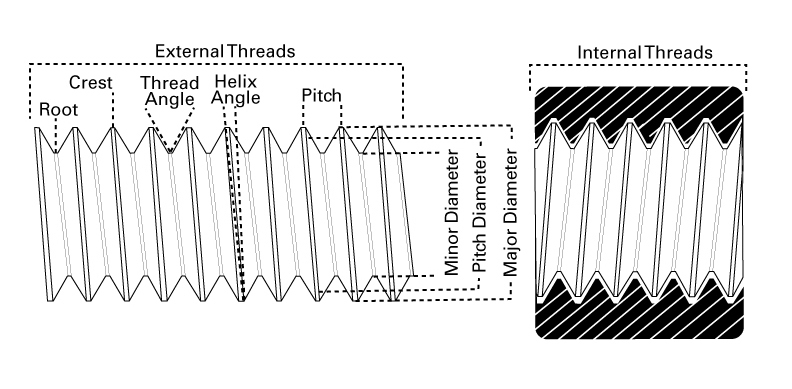

To effectively service fasteners and threaded components, it is important to have a working knowledge of threads. A thread is a continuous helical ridge formed on the inside (nut) or outside (screw) of a cylinder. This ridge is called the crest. Between each crest is a space, called the root. Threads are set at an angle to the axis of the bolt or nut. This slope is called the helix angle. The angle must be sloped, either upward to the right (for right-hand threaded screws) or upward to the left (for left-hand threaded screws). The thread forms a “V” shape between crests. The angle of this “V” is called the thread angle, and is determined by fastener engineers. Most screw threads used on a bicycle use a 60-degree thread angle.

For external threads (bolts), a right-hand thread slopes up to the right, but the internal right-hand thread slopes up to the left. For external left-hand threads, the threads slope up to the left, while the internal left-hand threads slope up to the right. The right-hand screw tightens clockwise (to the right). The left-hand screw tightens counter-clockwise (to the left). Left-hand threads on bicycles are seen on the drive side of bottom bracket and the left pedal. Notice the slope of the threads in the pedals threads below.

Threads are designated or named by two qualities: the external thread major diameter and the pitch measurement.

The major diameter is the outer diameter at the top of the thread crests. In Metric sizing, it is typical to to use the letter “M” before the bolt size, such as “M6” for a bolt with a 6 mm major diameter. Thread sizes are given in nominal sizes, so the exact measurement is generally slightly smaller than the specified size. For example, an M6 bolt may measure 5.8 mm or 5.9 mm, but it is called an M6 bolt. Note: The wrench size for the head of the bolt or nut is not used to determine the size of the thread. For example, the common M6 x 1.0 socket head cap screw uses a 5 mm hex wrench, yet the thread is not called M5.

Thread pitch is the distance from the crest of one thread to another crest measured along the length of the thread. Pitch is best measured using a thread pitch gauge.

So-called “English”/“Standard”/“Imperial”/“SAE” threads are designated by the frequency of how many threads are counted along one inch. This is called “Threads per Inch”, and is abbreviated as TPI. Metric threading uses the direct pitch measurement in millimeters from thread crest to the adjacent thread crest measured along the thread axis. An example of an SAE thread is 9/16″ x 20 TPI (pedal threads). An example of metric thread would be M10 x 1.0 (common rear derailleur bolt). NOTE: The term “Standard” threading is used primarily in the USA. The assumption in the USA is that the common SAE threading is the “standard.”

Typically, if a thread has a pitch designated as TPI, it is a SAE thread and the diameter is given in fractional inch sizes. If the pitch matches the metric standards, the diameter is given in millimeters. However, some thread standards will mix tpi with a metric diameter. Some Italian manufacturers use threads with a metric diameter and SAE thread pitches. For example, the “Italian” bottom bracket thread standard is 36 mm x 24 tpi, and some Italian-made rear axles are 10 mm x 26 tpi.

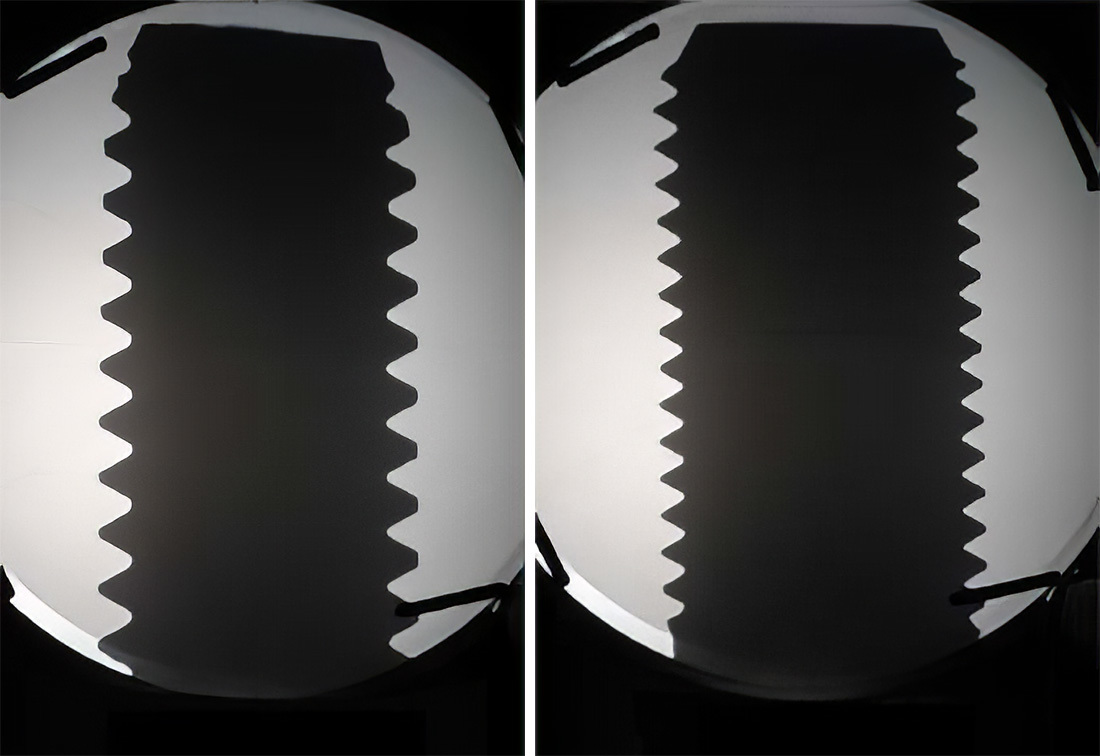

Threads are sometimes identified as “fine” or “coarse.” A fine thread will have a relatively small pitch measurement, and the threads will be closer together. A coarse thread has a relatively larger pitch measurement, and the threads will be further apart. Fine pitch threads are sometimes used to make adjustments. Derailleur adjusting screws are commonly a 0.75 mm pitch. A quarter of a turn on a derailleur screw advances the screw end only 0.19 mm. A fine thread will have less depth as compared to a coarse thread, and consequently are easier to strip. A coarse thread is more resistant to stripping but also less efficient in transmitting torque (turning) into thread tension. Generally, a fine pitch is easier to tighten in that tension is achieved at lower torques. In the image below, two bolts of the same diameter are magnified using an optical comparator. Notice the relatively coarser threads are deeper as compared to the fine threads.

For threads to interchange and match, both the diameter and pitch must match. Another critical aspect of thread fit and interchangeability is call pitch diameter. The pitch diameter is the diameter of the thread at a point where the width across the thread and the width across the groove between threads, are equal. Pitch diameter is difficult to measure directly without special instruments such as the optical comparator. For example, you may have one bottom bracket that seems to fit a bike shell easily. However, a replacement bottom bracket of a different brand may fit the same bike tightly. It is likely the two bottom brackets vary in pitch diameter.

Even when threads are properly sized, there will be play or slop between external and internal threads when engaged. This play is normal and disappears when the fastener is tightened. The thread can be a bit larger or smaller than ideal, and yet the part will still function adequately. However, if tolerances are exceeded, the part may require excessive force to install, or the fit may be quite sloppy, and the thread may fail during tightening.

Bolts and screws are made in different grades of strengths. There is a rating system that is used to mark and identify most industrial bolts. However, the bicycle industry typically uses proprietary bolts without any markings. The SAE (Society of Automotive Engineers) system rates bolts from grade 1 through grade 8. The tensile strength increases with the number. Metric bolts come with a “property class,” a two number system separated by a decimal point.

Tag » How To Read Screw Sizes

-

An Easy To Read Chart Of Screw Sizes And Thread Counts

-

How To Read Screw Sizes | Hunker

-

How To Read A Metric Screw Thread Callout - YouTube

-

How To Read A Screw Thread Callout: 12 Steps (with Pictures)

-

How To Measure Screw Thread Size - McMaster-Carr

-

Screw Size Chart: Find The Dimensions You Need

-

Fastener Guides - Measuring Screws And Bolts

-

Get To Know Metric Bolt Sizes - Insight Security

-

Imperial & Metric Thread Sizes Chart | CNCLATHING

-

How To Read Screw Thread Designation? - ExtruDesign

-

Understanding Metric Fasteners

-

Understanding Screw Sizes - Rockler

-

Guide To Fastener Sizes, Measurements - Screws, Nuts, Bolts ...