How To Read Screw Thread Designation? - ExtruDesign

Maybe your like

Have you ever wondered how to read the screw thread designation in engineering drawings? Sometimes it’s quite confusing to read the Hole thread designation on the drawings. Let us discuss How to read Screw Thread Designation from the hole or shaft screw thread callout on the engineering drawings.

Designation meaning: The act of indicating or identifying the purpose

According to the Indian standard IS: 4218 (Part IV) 1976 (Reaffirmed 1996), The screw thread designation callout must include two parts. One is the size designation and the other one is tolerance designation.

Size Designation

The size of the screw thread is designated by the letter “M” followed by the diameter and pitch, the two being separated by the sign ×. When there is no indication of the pitch, it shall mean that a coarse pitch is implied.

Tolerance designation

This Tolerance designation includes the following information on the screw thread callout leader note on the engineering drawing.

- A figure designating tolerance grade as indicated below:‘7’ for fine grade, ‘8’ for normal (medium) grade, and ‘9’ for coarse grade.

- A letter designating the tolerance position as indicated below :‘H’ for unit thread, ‘d’ for bolt thread with allowance, and ‘h’ for bolt thread withoutallowance.

For example, A bolt thread of 6 mm size of the coarse pitch and with allowance on the threads and normal (medium) tolerance grade is designated as M6-8d.

Screw Thread Designation for a tap hole with Example drawing

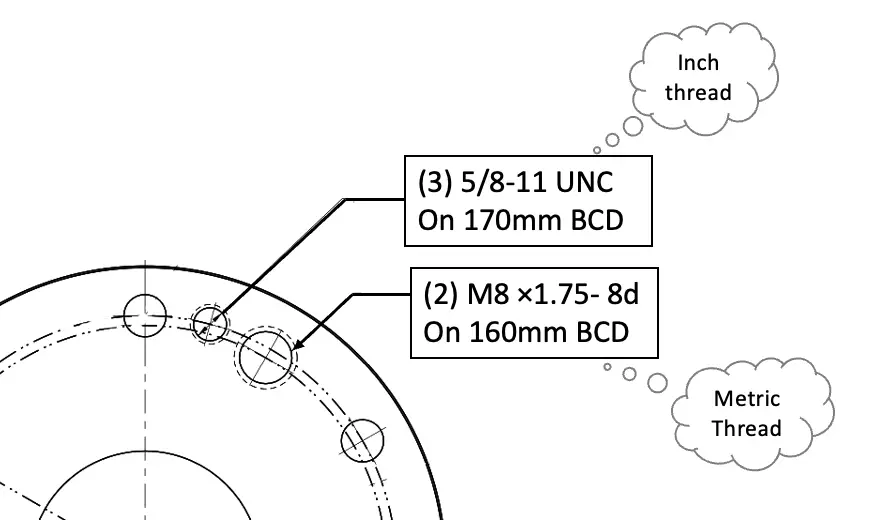

Let us have a closer look at an engineering drawing callout for a tap hole on the flange to understand the screw thread designation in a more detailed manner. Following is the screenshot of the tap hole callout.

In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems.

There are 3 parts for each callout.

- The first part represents the quantity of the hole. Which is 3 in the case of inch thread and 2 in the case of metric thread from the above tap hole callouts.

- The second part is the tap hole screw thread designation. (Discussed seperately for each unit system below)

- The third part is the Bolt Circle Diameter where the hole need to be placed.

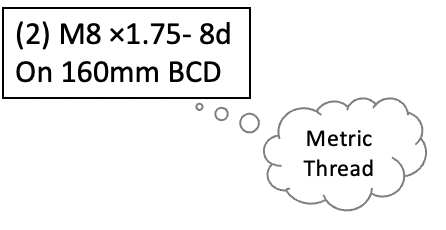

Metric Screw Thread Designation

From the Above Metric Screw thread designation for the tap hole callout, the M8x1.7 represents the screw thread size and 8d represents the tolerance details of the thread.

M8x1.7 = 8mm of the diameter and 1.75mm of pitch distance of each thread.

8d = 8 means a normal tolerance grade and d represents that there should be an allowance on the threads.

M8x1.75-8d = Thread diameter of 8mm with 1.75mm pitch of each thread with an allowance on the threads of normal tolerance grade.

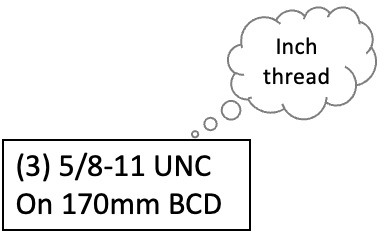

Inch Screw thread designation

From the above callout inch screw thread designation, 5/8-11 represents the Size of the screw thread and UNC/UNF represents the tolerance details.

5/8-11 = 0.625 inches diameter with 11 threads per inch

UNC/UNF = Unified National Coarse Thread / Unified National Fine Thread

The Unified National Coarse threads are comparable with the ISO metric threads.

5/8-11 UNC = a screw thread of 0.625inch diameter with 11 threads per inch of coarse threads.

UNC – Unified National Coarse Thread according ANSI B1.1

| Major Diameter | Threads per inch | Major Diameter | Major Diameter | Tap Drill Size | Pitch |

| (in) | (tpi) | (inch) | (mm) | (mm) | (mm) |

| #1 – 64 | 64 | 0.073 | 1.854 | 1.5 | 0.397 |

| #2 – 56 | 56 | 0.086 | 2.184 | 1.8 | 0.453 |

| #3 – 48 | 48 | 0.099 | 2.515 | 2.1 | 0.529 |

| #4 – 40 | 40 | 0.112 | 2.845 | 2.35 | 0.635 |

| #5 – 40 | 40 | 0.125 | 3.175 | 2.65 | 0.635 |

| #6 – 32 | 32 | 0.138 | 3.505 | 2.85 | 0.794 |

| #8 – 32 | 32 | 0.164 | 4.166 | 3.5 | 0.794 |

| #10 – 24 | 24 | 0.19 | 4.826 | 4 | 1.058 |

| #12 – 24 | 24 | 0.216 | 5.486 | 4.65 | 1.058 |

| 1/4″ – 20 | 20 | 0.25 | 6.35 | 5.35 | 1.27 |

| 5/16″ – 18 | 18 | 0.313 | 7.938 | 6.8 | 1.411 |

| 3/8″ – 16 | 16 | 0.375 | 9.525 | 8.25 | 1.587 |

| 7/16″ – 14 | 14 | 0.438 | 11.112 | 9.65 | 1.814 |

| 1/2″ – 13 | 13 | 0.5 | 12.7 | 11.15 | 1.954 |

| 9/16″ – 12 | 12 | 0.563 | 14.288 | 12.6 | 2.117 |

| 5/8″ – 11 | 11 | 0.625 | 15.875 | 14.05 | 2.309 |

| 3/4″ – 10 | 10 | 0.75 | 19.05 | 17 | 2.54 |

| 7/8″ – 9 | 9 | 0.875 | 22.225 | 20 | 2.822 |

| 1″ – 8 | 8 | 1 | 25.4 | 22.85 | 3.175 |

| 1 1/8″ – 7 | 7 | 1.125 | 28.575 | 25.65 | 3.628 |

| 1 1/4″ – 7 | 7 | 1.25 | 31.75 | 28.85 | 3.628 |

| 1 3/8″ – 6 | 6 | 1.375 | 34.925 | 31.55 | 4.233 |

| 1 1/2″ – 6 | 6 | 1.5 | 38.1 | 34.7 | 4.233 |

| 1 3/4″ – 5 | 5 | 1.75 | 44.45 | 40.4 | 5.08 |

| 2″ – 4 1/2 | 4 1/2 | 2 | 50.8 | 46.3 | 5.644 |

| 2 1/4″ – 4 1/2 | 4 1/2 | 2.25 | 57.15 | 52.65 | 5.644 |

| 2 1/2″ – 4 | 4 | 2.5 | 63.5 | 58.5 | 6.35 |

| 2 3/4″ – 4 | 4 | 2.75 | 69.85 | 64.75 | 6.35 |

| 3″ – 4 | 4 | 3 | 76.2 | 71.1 | 6.35 |

| 3 1/4″ – 4 | 4 | 3.25 | 82.55 | 77.45 | 6.35 |

| 3 1/2″ – 4 | 4 | 3.5 | 88.9 | 83.8 | 6.35 |

| 3 3/4″ – 4 | 4 | 3.75 | 95.25 | 90.15 | 6.35 |

| 4″ – 4 | 4 | 4 | 101.6 | 96.5 | 6.35 |

UNF – Unified National Fine Thread according ANSI B1.1

| Major Diameter | Threads per inch | Major Diameter | Major Diameter | Tap Drill Size | Pitch |

| (in) | (tpi) | (inch) | (mm) | (mm) | (mm) |

| #0 – 80 | 80 | 0.06 | 1.524 | 1.25 | 0.317 |

| #1 – 72 | 72 | 0.073 | 1.854 | 1.55 | 0.353 |

| #2 – 64 | 64 | 0.086 | 2.184 | 1.9 | 0.397 |

| #3 – 56 | 56 | 0.099 | 2.515 | 2.15 | 0.453 |

| #4 – 48 | 48 | 0.112 | 2.845 | 2.4 | 0.529 |

| #5 – 44 | 44 | 0.125 | 3.175 | 2.7 | 0.577 |

| #6 – 40 | 40 | 0.138 | 3.505 | 2.95 | 0.635 |

| #8 – 36 | 36 | 0.164 | 4.166 | 3.5 | 0.705 |

| #10 – 32 | 32 | 0.19 | 4.826 | 4.1 | 0.794 |

| #12 – 28 | 28 | 0.216 | 5.486 | 4.7 | 0.907 |

| 1/4″ – 28 | 28 | 0.25 | 6.35 | 5.5 | 0.907 |

| 5/16″ – 24 | 24 | 0.313 | 7.938 | 6.9 | 1.058 |

| 3/8″ – 24 | 24 | 0.375 | 9.525 | 8.5 | 1.058 |

| 7/16″ – 20 | 20 | 0.438 | 11.112 | 9.9 | 1.27 |

| 1/2″ – 20 | 20 | 0.5 | 12.7 | 11.5 | 1.27 |

| 9/16″ – 18 | 18 | 0.563 | 14.288 | 12.9 | 1.411 |

| 5/8″ – 18 | 18 | 0.625 | 15.875 | 14.5 | 1.411 |

| 3/4″ – 16 | 16 | 0.75 | 19.05 | 17.5 | 1.587 |

| 7/8″ – 14 | 14 | 0.875 | 22.225 | 20.4 | 1.814 |

| 1″ – 12 | 12 | 1 | 25.4 | 23.25 | 2.117 |

| 1 1/8″ – 12 | 12 | 1.125 | 28.575 | 26.5 | 2.117 |

| 1 1/4″ – 12 | 12 | 1.25 | 31.75 | 29.5 | 2.117 |

| 1 3/8″ – 12 | 12 | 1.375 | 34.925 | 32.75 | 2.117 |

| 1 1/2″ – 12 | 12 | 1.5 | 38.1 | 36 | 2.117 |

Standard Dimensions of Screw Threads for Bolt and Nuts

According to IS : 4218 (Part III) 1976 (Reaffirmed 1996)

Metric Threads Coarse Threads Series

| Designation | Pitch mm | Major or nominal diameter for Nut and Bolt (d = D) mm | Effective or pitch diameter for Nut and Bolt (dp) mm | Minor or core diameter (dc) for Bolt in mm | Minor or core diameter (dc) for Nut in mm | Depth of thread for bolt -mm | Stress area mm2 |

| M 0.4 | 0.1 | 0.400 | 0.335 | 0.277 | 0.292 | 0.061 | 0.074 |

| M 0.6 | 0.15 | 0.600 | 0.503 | 0.416 | 0.438 | 0.092 | 0.166 |

| M 0.8 | 0.2 | 0.800 | 0.670 | 0.555 | 0.584 | 0.123 | 0.295 |

| M 1 | 0.25 | 1.000 | 0.38 | 0.693 | 0.729 | 0.153 | 0.460 |

| M 12 | 0.25 | 1.200 | 1.038 | 0.893 | 0.929 | 0.158 | 0.732 |

| M 1.4 | 0.3 | 1.400 | 1.205 | 1.032 | 1.075 | 0.184 | 0.983 |

| M 1.6 | 0.35 | 1.600 | 1.373 | 1.171 | 1.221 | 0.215 | 1.27 |

| M 1.8 | 0.35 | 1.800 | 1873 | 1.371 | 1.421 | 0.215 | 1.70 |

| M 2 | 0.4 | 2.000 | 1.740 | 1.509 | 1.567 | 0.245 | 2.07 |

| M 22 | 0.45 | 2.200 | 1.908 | 1.648 | 1.713 | 0.276 | 2.48 |

| M 25 | 0.45 | 2.500 | 2.208 | 1.948 | 2.013 | 0.276 | 3.39 |

| M 3 | 0.5 | 3.000 | 2.675 | 2.387 | 2.459 | 0.307 | 5.03 |

| M 35 | 0.6 | 3.500 | 3.110 | 2.764 | 2.850 | 0.368 | 6.78 |

| M 4 | 0.7 | 4.000 | 3.545 | 3.141 | 3.242 | 0.429 | 8.78 |

| M 4.5 | 0.75 | 4.500 | 4.013 | 3580 | 3.688 | 0.460 | 11.3 |

| M 5 | 0.8 | 5.000 | 4.480 | 4.019 | 4.134 | 0.491 | 14.2 |

| M 6 | 1 | 6.000 | 5350 | 4.773 | 4.918 | 0.613 | 20.1 |

| M7 | 1 | 7.000 | 6.350 | 5.773 | 5.918 | 0.613 | 28.9 |

| M8 | 1.25 | 8.000 | 7.188 | 6.466 | 6.647 | 0.767 | 36.6 |

| M 10 | 1.5 | 10.000 | 9.026 | 8.160 | 8.876 | 0.920 | 58.3 |

| M 12 | 1.75 | 12.000 | 10.863 | 9.858 | 10.106 | 1.074 | 84.0 |

| M 14 | 2 | 14.000 | 12.701 | 11.546 | 11.835 | 1.227 | 115 |

| M 16 | 2 | 16.000 | 14.701 | 13.546 | 13.835 | 1.227 | 157 |

| M 18 | 2.5 | 18.000 | 16.376 | 14.933 | 15.294 | 1.534 | 192 |

| M 20 | 2.5 | 20.000 | 18.376 | 16.933 | 17.294 | 1.534 | 245 |

| M 22 | 2.5 | 22.000 | 20.376 | 18.933 | 19.294 | 1.534 | 303 |

| M 24 | 3 | 24.000 | 22.051 | 20.320 | 20.752 | 1.840 | 353 |

| M 27 | 3 | 27.000 | 25.051 | 23.320 | 23.752 | 1.840 | 459 |

| M 30 | 3.5 | 30.000 | 27.727 | 25.706 | 26.211 | 2.147 | 561 |

| M 33 | 3.5 | 33.000 | 30.727 | 28.706 | 29.211 | 2.147 | 694 |

| M 36 | 4 | 36.000 | 33.402 | 31.093 | 31.670 | 2.454 | 817 |

| M 39 | 4 | 39.000 | 36.402 | 34.093 | 34.670 | 2.454 | 976 |

| M 42 | 4.5 | 42.000 | 39.077 | 36.416 | 37.129 | 2.760 | 1104 |

| M 45 | 4.5 | 45.000 | 42.077 | 39.416 | 40.129 | 2.760 | 1300 |

| M 48 | 5 | 48.000 | 44.752 | 41.795 | 42.587 | 3.067 | 1465 |

| M 52 | 5 | 52.000 | 48.752 | 45.795 | 46.587 | 3.067 | 1755 |

| M 56 | 5.5 | 56.000 | 52.428 | 49.177 | 50.046 | 3.067 | 2022 |

| M 60 | 5.5 | 60.000 | 56.428 | 53.177 | 54.046 | 3.374 | 2360 |

Metric Threads Fine Thread Series

| Designation | Pitch mm | Major or nominal diameter for Nut and Bolt (d = D) mm | Effective or pitch diameter for Nut and Bolt (dp) mm | Minor or core diameter (dc) for Bolt in mm | Minor or core diameter (dc) for Nut in mm | Depth of thread for bolt -mm | Stress area mm2 |

| M 0.4 | 0.1 | 0.400 | 0.335 | 0.277 | 0.292 | 0.061 | 0.074 |

| M 0.6 | 0.15 | 0.600 | 0.503 | 0.416 | 0.438 | 0.092 | 0.166 |

| M 0.8 | 0.2 | 0.800 | 0.670 | 0.555 | 0.584 | 0.123 | 0.295 |

| M1 | 0.25 | 1.000 | 0.838 | 0.693 | 0.729 | 0.153 | 0.460 |

| M 1.2 | 0.25 | 1.200 | 1.038 | 0.893 | 0.929 | 0.158 | 0.732 |

| M 1.4 | 0.3 | 1.400 | 1.205 | 1.032 | 1.075 | 0.184 | 0.983 |

| M 1.6 | 0.35 | 1.600 | 1.373 | 1.171 | 1.221 | 0.215 | 1.27 |

| M 1.8 | 0.35 | 1.800 | 1.573 | 1.371 | 1.421 | 0.215 | 1.70 |

| M2 | 0.4 | 2.000 | 1.740 | 1.509 | 1.567 | 0.245 | 2.07 |

| M 2.2 | 0.45 | 2.200 | 1.908 | 1.648 | 1.713 | 0.276 | 2.48 |

| M 2.5 | 0.45 | 2.500 | 2.208 | 1.948 | 2.013 | 0.276 | 3.39 |

| M3 | 0.5 | 3.000 | 2.675 | 2.387 | 2.459 | 0.307 | 5.03 |

| M 3.5 | 0.6 | 3.500 | 3.110 | 2.764 | 2.850 | 0.368 | 6.78 |

| M4 | 0.7 | 4.000 | 3.545 | 3.141 | 3.242 | 0.429 | 8.78 |

| M 4.5 | 0.75 | 4.500 | 4.013 | 3.580 | 3.688 | 0.460 | 11.3 |

| MS | 0.8 | 5.000 | 4.480 | 4.019 | 4.134 | 0.491 | 14.2 |

| M6 | 1 | 6.000 | 5.350 | 4.773 | 4.918 | 0.613 | 20.1 |

Metric Screw Threads – Coarse Threads according ISO 724

| Size – Nominal Diameter | Pitch | Clearance Drill | Tap Drill | TensileStress Area |

| (mm) | (mm) | (mm) | (mm) | (mm2) |

| M 1.6 | 0.35 | 1.8 | 1.25 | |

| M 2 | 0.4 | 2.4 | 1.6 | |

| M 2.5 | 0.45 | 2.9 | 2 | |

| M 3 | 0.5 | 3.4 | 2.5 | |

| M 3.5 | 0.6 | 3.9 | 2.9 | |

| M 4 | 0.7 | 4.5 | 3.3 | 8.78 |

| M 5 | 0.8 | 5.5 | 4.2 | 14.2 |

| M 6 | 1 | 6.6 | 5 | 20.1 |

| M 8 | 1.25 | 9 | 6.8 | 36.6 |

| M 10 | 1.5 | 12 | 8.5 | 58 |

| M 12 | 1.75 | 14 | 10.2 | 84.3 |

| M 14 | 2 | 16 | 12 | |

| M 16 | 2 | 18 | 14 | 157 |

| M 20 | 2.5 | 22 | 17.5 | 245 |

| M 22 | 2.5 | 25 | 19.5 | |

| M 24 | 3 | 27 | 21 | 353 |

| M 27 | 3 | 30 | 24 | |

| M 30 | 3.5 | 33 | 26.5 | 561 |

| M 36 | 4 | 40 | 32 | 817 |

| M 42 | 4.5 | 46 | 37.5 | 1120 |

| M 48 | 5 | 53 | 43 | 1470 |

| M 56 | 5.5 | 62 | 50.5 | 2030 |

| M 64 | 6 | 70 | 58 | 2680 |

| M 68 | 6 | 74 | 62 |

Metric Screw Threads – Fine Threads according ISO 724

| Size – Nominal Diameter | Pitch | Tap Drill | TensileStress Area |

| (mm) | (mm) | (mm) | (mm2) |

| M 1.0 x 0.2 | 0.2 | 0.8 | |

| M 1.1 x 0.2 | 0.2 | 0.9 | |

| M 1.2 x 0.2 | 0.2 | 1 | |

| M 1.4 x 0.2 | 0.2 | 1.2 | |

| M 1.6 x 0.2 | 0.2 | 1.4 | |

| M 1.8 x 0.2 | 0.2 | 1.6 | |

| M 2 x 0.25 | 0.25 | 1.75 | |

| M 2.2 x 0.25 | 0.25 | 1.95 | |

| M 2.5 x 0.35 | 0.35 | 2.1 | |

| M 3 x 0.35 | 0.35 | 2.6 | |

| M 3.5 x 0.35 | 0.35 | 3.1 | |

| M 4 x 0.5 | 0.5 | 3.5 | |

| M 4.5 x 0.5 | 0.5 | 4 | |

| M 5 x 0.5 | 0.5 | 4.5 | |

| M 5.5 x 0.5 | 0.5 | 5 | |

| M 6 x 0.75 | 0.75 | 5.2 | 20.1 |

| M 7 x 0.75 | 0.75 | 6.2 | |

| M 8 x 0.75 | 0.75 | 7.2 | |

| M 8 x 1.0 | 1 | 7 | 39.2 |

| M 9 x 0.75 | 0.75 | 8.2 | |

| M 9 x 1 | 1 | 8 | |

| M 10 x 0.75 | 0.75 | 9.2 | |

| M 10 x 1 | 1 | 9 | 64.5 |

| M 10 x 1.25 | 1.25 | 8.8 | 61.2 |

| M 11 x 0.75 | 0.75 | 10.2 | |

| M 11 x 1 | 1 | 10 | |

| M 12 x 1 | 1 | 11 | |

| M 12 x 1.25 | 1.25 | 10.8 | 92.1 |

| M 12 x 1.5 | 1.5 | 10.5 | 88.1 |

| M 14 x 1.0 | 1 | 13 | |

| M 14 x 1.25 | 1.25 | 12.8 | |

| M 14 x 1.5 | 1.5 | 12.5 | |

| M 15 x 1 | 1 | 14 | |

| M 15 x 1.5 | 1.5 | 13.5 | |

| M 16 x 1 | 1 | 15 | 178 |

| M 16 x 1.5 | 1.5 | 14.5 | 167 |

| M 17 x 1.0 | 1 | 16 | |

| M 17 x 1.5 | 1.5 | 15.5 | |

| M 18 x 1.0 | 1 | 17 | |

| M 18 x 1.5 | 1.5 | 16.5 | |

| M 18 x 2.0 | 2 | 16 | |

| M 20 x 1.0 | 1 | 19 | |

| M 20 x 1.5 | 1.5 | 18.5 | 272 |

| M 20 x 2.0 | 2 | 18 | 258 |

| M 22 x 1.0 | 1 | 21 | |

| M 22 x 1.5 | 1.5 | 20.5 | |

| M 22 x 2.0 | 2 | 20 | |

| M 24 x 1.0 | 1 | 23 | |

| M 24 x 1.5 | 1.5 | 22.5 | 401 |

| M 24 x 2.0 | 2 | 22 | 384 |

| M 25 x 1.0 | 1 | 24 | |

| M 25 x 1.5 | 1.5 | 23.5 | |

| M 25 x 2.0 | 2 | 23 | |

| M 27 x 1.0 | 1 | 26 | |

| M 27 x 1.5 | 1.5 | 25.5 | |

| M 27 x 2.0 | 2 | 25 | |

| M 28 x 1.0 | 1 | 27 | |

| M 28 x 1.5 | 1.5 | 26.5 | |

| M 28 x 2.0 | 2 | 26 | |

| M 30 x 1.0 | 1 | 29 | |

| M 30 x 1.5 | 1.5 | 28.5 | |

| M 30 x 2.0 | 2 | 28 | 621 |

| M 30 x 3.0 | 3 | 27 | 581 |

| M 32 x 1.5 | 1.5 | 30.5 | |

| M 32 x 2.0 | 2 | 30 | |

| M 33 x 1.5 | 1.5 | 31.5 | |

| M 33 x 2.0 | 2 | 31 | |

| M 33 x 3.0 | 3 | 30 | |

| M 35 x 1.5 | 1.5 | 33.5 | |

| M 35 x 2.0 | 2 | 33 | |

| M 36 x 1.5 | 1.5 | 34.5 | |

| M 36 x 2.0 | 2 | 34 | 915 |

| M 36 x 3.0 | 3 | 33 | 865 |

| M 39 x 1.5 | 1.5 | 37.5 | |

| M 39 x 2.0 | 2 | 37 | |

| M 39 x 3.0 | 3 | 36 | |

| M 40 x 1.5 | 1.5 | 38.5 | |

| M 40 x 2.0 | 2 | 38 | |

| M 40 x 3.0 | 3 | 37 | |

| M 42 x 1.5 | 1.5 | 40.5 | |

| M 42 x 2.0 | 2 | 40 | |

| M 42 x 3.0 | 3 | 39 | 1210 |

| M 42 x 4.0 | 4 | 38 | 1150 |

| M 45 x 1.5 | 1.5 | 43.5 | |

| M 45 x 2.0 | 2 | 43 | |

| M 45 x 3.0 | 3 | 42 | |

| M 45 x 4.0 | 4 | 41 | |

| M 48 x 1.5 | 1.5 | 46.5 | |

| M 48 x 2.0 | 2 | 46 | |

| M 48 x 3.0 | 3 | 45 | 1600 |

| M 48 x 4.0 | 4 | 44 | 1540 |

| M 50 x 1.5 | 1.5 | 48.5 | |

| M 50 x 2.0 | 2 | 48 | |

| M 50 x 3.0 | 3 | 47 | |

| M 52 x 1.5 | 1.5 | 50.5 | |

| M 52 x 2.0 | 2 | 50 | |

| M 52 x 3.0 | 3 | 49 | |

| M 52 x 4.0 | 4 | 48 | |

| M 55 x 1.5 | 1.5 | 53.5 | |

| M 55 x 2.0 | 2 | 53 | |

| M 55 x 3.0 | 3 | 52 | |

| M 55 x 4.0 | 4 | 51 | |

| M 56 x 1.5 | 1.5 | 54.5 | |

| M 56 x 2.0 | 2 | 54 | |

| M 56 x 3.0 | 3 | 53 | |

| M 56 x 4.0 | 4 | 52 | |

| M 58 x 1.5 | 1.5 | 56.5 | |

| M 58 x 2.0 | 2 | 56 | |

| M 58 x 3.0 | 3 | 55 | |

| M 58 x 4.0 | 4 | 54 | |

| M 60 x 1.5 | 1.5 | 58.5 | |

| M 60 x 2.0 | 2 | 58 | |

| M 60 x 3.0 | 3 | 57 | |

| M 60 x 4.0 | 4 | 56 | |

| M 62 x 1.5 | 1.5 | 60.5 | |

| M 62 x 2.0 | 2 | 60 | |

| M 62 x 3.0 | 3 | 59 | |

| M 62 x 4.0 | 4 | 58 | |

| M 64 x 1.5 | 1.5 | 62.5 | |

| M 64 x 2.0 | 2 | 62 | |

| M 64 x 3.0 | 3 | 61 | |

| M 64 x 4.0 | 4 | 60 | |

| M 65 x 1.5 | 1.5 | 63.5 | |

| M 65 x 2.0 | 2 | 63 | |

| M 65 x 3.0 | 3 | 62 | |

| M 65 x 4.0 | 4 | 61 | |

| M 68 x 1.5 | 1.5 | 66.5 | |

| M 68 x 2.0 | 2 | 66 | |

| M 68 x 3.0 | 3 | 65 | |

| M 68 x 4.0 | 4 | 64 | |

| M 70 x 1.5 | 1.5 | 68.5 | |

| M 70 x 2.0 | 2 | 68 | |

| M 70 x 3.0 | 3 | 67 | |

| M 70 x 4.0 | 4 | 66 | |

| M 70 x 6.0 | 6 | 64 | |

| M 72 x 1.5 | 1.5 | 70.5 | |

| M 72 x 2.0 | 2 | 70 | |

| M 72 x 3.0 | 3 | 69 | |

| M 72 x 4.0 | 4 | 68 | |

| M 72 x 6.0 | 6 | 66 | |

| M 75 x 1.5 | 1.5 | 73.5 | |

| M 75 x 2.0 | 2 | 73 | |

| M 75 x 3.0 | 3 | 72 | |

| M 75 x 4.0 | 4 | 71 | |

| M 75 x 6.0 | 6 | 69 | |

| M 76 x 1.5 | 1.5 | 74.5 | |

| M 76 x 2.0 | 2 | 74 | |

| M 76 x 3.0 | 3 | 73 | |

| M 76 x 4.0 | 4 | 72 | |

| M 76 x 6.0 | 6 | 70 | |

| M 80 x 1.5 | 1.5 | 78.5 | |

| M 80 x 2.0 | 2 | 78 | |

| M 80 x 3.0 | 3 | 77 | |

| M 80 x 4.0 | 4 | 76 | |

| M 80 x 6.0 | 6 | 74 | |

| M 85 x 2.0 | 2 | 83 | |

| M 85 x 3.0 | 3 | 82 | |

| M 85 x 4.0 | 4 | 81 | |

| M 85 x 6.0 | 6 | 79 | |

| M 90 x 2.0 | 2 | 88 | |

| M 90 x 3.0 | 3 | 87 | |

| M 90 x 4.0 | 4 | 86 | |

| M 90 x 6.0 | 6 | 84 | |

| M 95 x 2.0 | 2 | 93 | |

| M 95 x 3.0 | 3 | 92 | |

| M 95 x 4.0 | 4 | 91 | |

| M 95 x 6.0 | 6 | 89 | |

| M 100 x 2.0 | 2 | 98 | |

| M 100 x 3.0 | 3 | 97 | |

| M 100 x 4.0 | 4 | 96 | |

| M 100 x 6.0 | 6 | 94 |

Conclusion: The above-given list of the threads is not the complete list. ISO 724 provides thread sizes up to 300. let us know in the comment section below if you understood how to read your screws threads on the drawings correctly.

Tag » How To Read Screw Sizes

-

An Easy To Read Chart Of Screw Sizes And Thread Counts

-

How To Read Screw Sizes | Hunker

-

How To Read A Metric Screw Thread Callout - YouTube

-

How To Read A Screw Thread Callout: 12 Steps (with Pictures)

-

How To Measure Screw Thread Size - McMaster-Carr

-

Screw Size Chart: Find The Dimensions You Need

-

Fastener Guides - Measuring Screws And Bolts

-

Get To Know Metric Bolt Sizes - Insight Security

-

Imperial & Metric Thread Sizes Chart | CNCLATHING

-

Understanding Metric Fasteners

-

Basic Thread Concepts | Park Tool

-

Understanding Screw Sizes - Rockler

-

Guide To Fastener Sizes, Measurements - Screws, Nuts, Bolts ...