Sweating A Vertical Copper Joint - Fine Homebuilding

Maybe your like

- How-To

- Design

- Tools & Materials

- Restoration

- Videos

- Blogs

- Forum

- Magazine

- Members

- FHB House

- Podcast

Is there a trick to sweating a vertical pipe joint? I have succesfully sweated many joints horizontally but I can’t avoid this one vertical one.

I have done some FHB and internet searches that offered no specific help.

I used emory cloth to get the pipe and fitting ends extremely shinny. They are dry. But the solder will not suck up into the joint. Maybe I’m using to much flux, or not enough. Are the pre-soldered fittings the answer?

Thanks.

ReplyReplies

-

DanH | Dec 08, 2006 07:17pm | #1

DanH | Dec 08, 2006 07:17pm | #1 If the joint is clean and properly fluxed and hot enough, capillary action should suck solder up into the joint. It won't work until the joint is hot enough to keep the solder fully fluid as it's sucked into the joint, and won't work if the flux is burned out from overheating before the joint is made.

Of course, you need to have an opening on the line somewhere (open faucet or valve, or the other end of the pipe simply not connected yet) so that air pressure doesn't build up inside and blow the solder out.

And of course you can't have water in the lines anywhere near the joint.

I did have a lot of trouble once with some mis-sized pipe. It wasn't perfectly round but had a slight flat on one side and was overall a bit undersized. You could have the same sort of problem with bad fittings. Since you're relying on capillary action, the space between pipe and fitting needs to be fairly tight (though not so tight that you have to force the pieces together).

People never lie so much as before an election, during a war, or after a hunt. --Otto von Bismarck -

TWG | Dec 08, 2006 07:24pm | #3

TWG | Dec 08, 2006 07:24pm | #3 Thanks DanH,

An out of round fitting may be the answer. There is a little wiggle in the dry fitting.

-

DanH | Dec 08, 2006 07:33pm | #4

DanH | Dec 08, 2006 07:33pm | #4 If it's poor fit you'll likely notice that the solder wicks into the joint for part of the diamater, but leaves a gap on one side, where the fit is worst. If the solder is just "standing" on the joint and not getting sucked in at all it's either too cold or not properly cleaned and fluxed. People never lie so much as before an election, during a war, or after a hunt. --Otto von Bismarck

-

tb1472000 | Dec 08, 2006 07:20pm | #2

tb1472000 | Dec 08, 2006 07:20pm | #2 The trick is to ensure the joint is hot enough. The solder should flow right up into the joint. I don't find it any different than the joint being horizontal. Now if there is any water in the pipe, that will cause a problem. The water doesn't allow the joint to get hot enough. I've usually found when I have problems soldering copper pipes, it is because there is too much water left in the pipe.

-

JAlden | Dec 08, 2006 07:50pm | #5

JAlden | Dec 08, 2006 07:50pm | #5 What kind of torch and tip are you using? It may not be getting hot enough.

Other than that, Dan has you covered.

-

gravel | Dec 08, 2006 07:52pm | #6

gravel | Dec 08, 2006 07:52pm | #6 I had a similar problem recently and found that just enough water was dripping to keep the joint from heating properly. My dad told me about an old plumber's trick of stuffing a small piece of bread above the fitting to stop the drips. Worked like a champ although I did have to clean a few mushy bread remnants from the screen for the faucet.

-

DougU | Dec 08, 2006 08:12pm | #7

DougU | Dec 08, 2006 08:12pm | #7 Gravel

Thats an old trick that works well but the first rule is you have to take the screen off the faucet! Of course you know that now dont you. :)

Oh, and dont use bread with the little chunks of grain it it.

Doug

-

TWG | Dec 08, 2006 08:22pm | #8

TWG | Dec 08, 2006 08:22pm | #8 The fitting was out of round. It worked my first attempt with a new fitting.

This concludes my installation of the new Frig with water line. Back to the woodshop.

On a side note, I think those saddle valves that come with the frig water kits are junk. I could not get it tight enough to keep the washer from dripping. This led to a regular brass valve instead.

Thanks everyone for their advice.

-

MikeHennessy | Dec 08, 2006 08:31pm | #9

MikeHennessy | Dec 08, 2006 08:31pm | #9 Six steps to soldering vertical joints:

1) Clean parts, male and female, with emery cloth till they shine like a new penny. I make sure to get the edges of the female fitting cleaned as well, but not everyone does.2) Apply flux to both parts, coating all mating surfaces.(Optional for problematic joints -- tin the male fitting by heating it, fully coating the mating surface with solder and, while it's still molten, immediately wipe clean with a dry rag. You should wind up with a surface that looks "chrome plated", i.e., tinned, but not heavily coated with solder. Re-apply flux & proceed with step 3.)3) Assemble joint.4) Heat the female fitting, applying the flame as far as possible from the end of the fitting where you will apply solder.5) Apply solder all around the joint -- it will wick into the fitting -- keeping the torch on the fitting, if necessary, as far away from the point of solder application as possible. Remember that the solder will flow towards the hot part of the work.6) While still hot, wipe around the joint with a dry rag to remove excess solder & examine for any gaps.

Mike HennessyPittsburgh, PA

-

mrfixitusa | Dec 08, 2006 08:44pm | #10

mrfixitusa | Dec 08, 2006 08:44pm | #10 Sometimes problems result when you cut out a section of the existing copper.For me, if I have enough room to spin the tubing cutter the full 360 degrees then I will have a nice clean cut.Where I have problems is when I'm in a tight spot and can't spin the tubing cutter the full 360.If I can't turn in the full 360 I'm better off using a hacksaw blade or maybe a dremel tool etc.^^^^^^

S N A F U (Situation Normal: All Fouled Up)

-

Renoun | Dec 11, 2006 09:03am | #11

Renoun | Dec 11, 2006 09:03am | #11 Go talk to the folks at your local plumbing supply house. There are now tubing cutters available for specific pipe sizes that only require around an inch of clearance.

View Image

Actually you can just order one from from Amazon now.

-

mrfixitusa | Dec 11, 2006 03:35pm | #12

mrfixitusa | Dec 11, 2006 03:35pm | #12 Cool - hey thanks a lot !^^^^^^

S N A F U (Situation Normal: All Fouled Up)

Log in or create an account to post a comment.

Sign up Log inBecome a member and get full access to FineHomebuilding.com

Video Shorts

Categories

- Business

- Code Questions

- Construction Techniques

- Energy, Heating & Insulation

- General Discussion

- Help/Work Wanted

- Photo Gallery

- Reader Classified

- Tools for Home Building

Recent Posts and Replies

- |

- |

- |

- |

- |

- |

Featured Story

What You Missed at the 2025 Fine Homebuilding Summit

What You Missed at the 2025 Fine Homebuilding Summit This year's Fine Homebuilding Summit was possibly the best event of the year.

Featured Video

How to Install Cable Rail Around Wood-Post Corners

How to Install Cable Rail Around Wood-Post Corners Use these tips to keep cables tight and straight for a professional-looking deck-railing job.

Related Stories

-

Podcast Episode 717: Best of FHB Podcast, Volume 10

Podcast Episode 717: Best of FHB Podcast, Volume 10 -

Podcast Episode 716: Shop Foundations, Steam Showers, and Sealing a Brick Crawlspace

Podcast Episode 716: Shop Foundations, Steam Showers, and Sealing a Brick Crawlspace -

FHB Podcast Segment: Building Science Considerations for Steam Showers

FHB Podcast Segment: Building Science Considerations for Steam Showers -

Tips for Every Tool

Tips for Every Tool

Highlights

Plus, get an extra 20% off with code GIFT20

Plus, get an extra 20% off with code GIFT20 "I have learned so much thanks to the searchable articles on the FHB website. I can confidently say that I expect to be a life-long subscriber." - M.K.

Get home building tips, offers, and expert advice in your inbox

Sign UpSigning you up...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. See all newsletters See all newslettersFine Homebuilding Magazine

-

Issue 336 - Dec/Jan 2026

Issue 336 - Dec/Jan 2026 - Tool Test: Cordless Framing Nailers

- Installing an ERV or HRV

- Ease the Pane of Window Selection

-

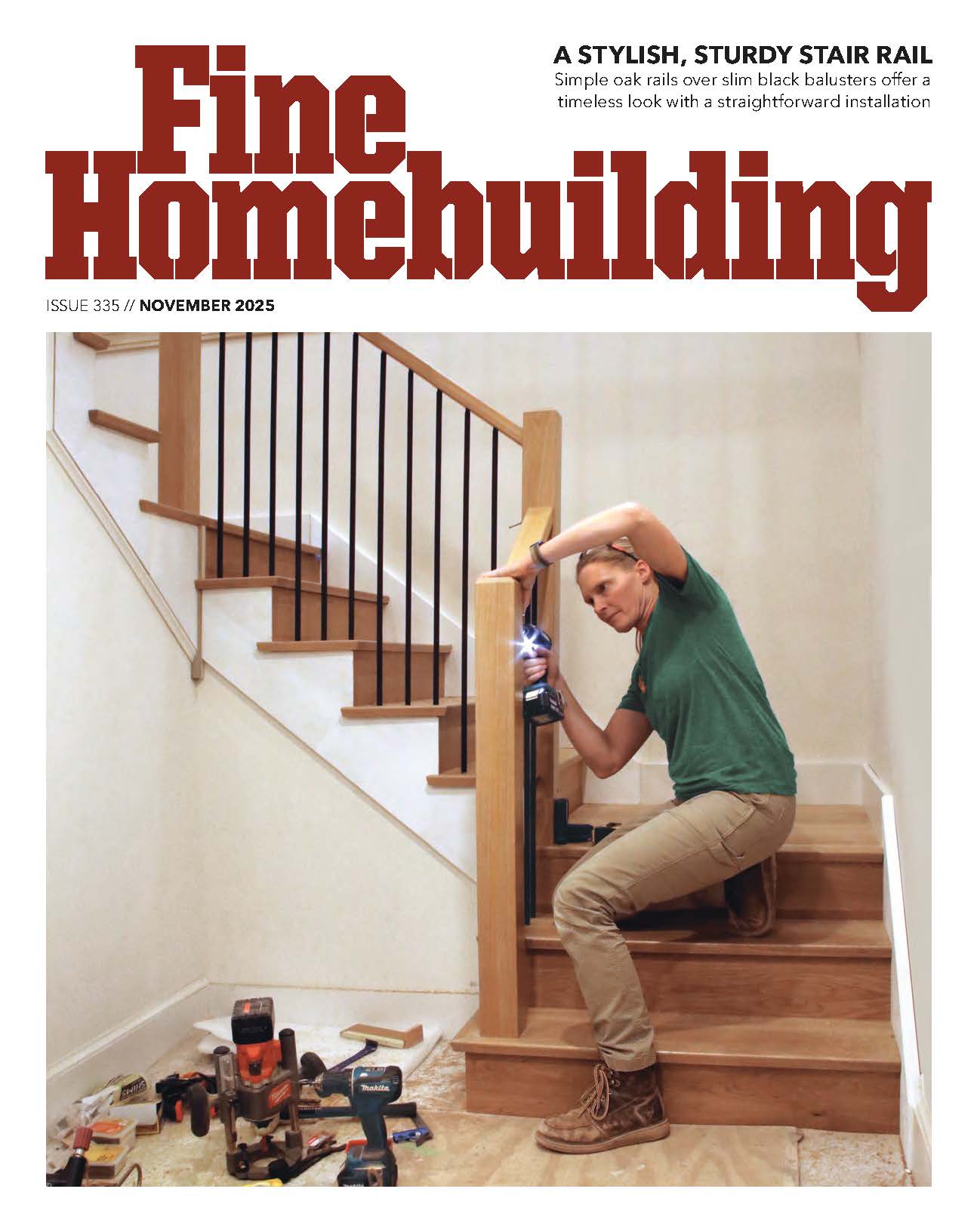

Issue 335 - November 2025

Issue 335 - November 2025 - A Stylish, Sturdy Stair Rail

- Rock-Solid Framed Floors

- Smart Vapor Retarders

-

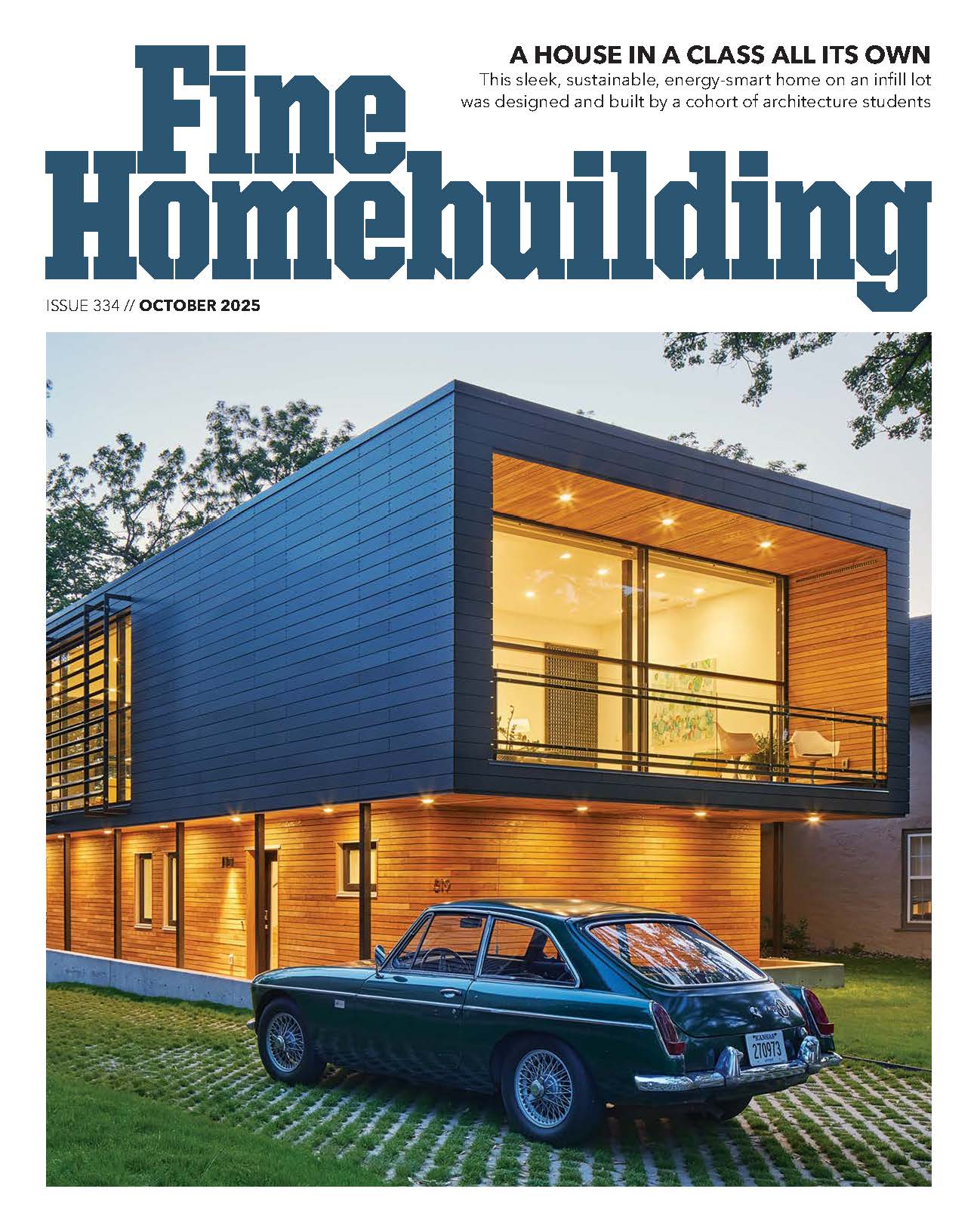

Issue 334 - October 2025

Issue 334 - October 2025 - Student Housing

- New Stairs for an Old House

- Do Safer Strippers Work?

-

Issue 333 - August/September 2025

Issue 333 - August/September 2025 - A Practical Perfect Wall

- Landscape Lighting Essentials

- Repairing a Modern Window Sash

-

Issue 332 - July 2025

Issue 332 - July 2025 - Custom Built-ins With Job-Site Tools

- Fight House Fires Through Design

- Making the Move to Multifamily

Fine Home Building

Newsletter Sign-up

-

Fine Homebuilding

Home building tips, offers, and expert advice in your inbox.

-

Green Building Advisor

Building science and energy efficiency advice, plus special offers, in your inbox.

-

Old House Journal

Repair, renovation, and restoration tips, plus special offers, in your inbox.

Signing you up...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. See all newslettersFollow

-

Fine Homebuilding

Dig into cutting-edge approaches and decades of proven solutions with total access to our experts and tradespeople.

Start Free Trial Now- X

-

GBA Prime

Get instant access to the latest developments in green building, research, and reports from the field.

Start Free Trial Now- YouTube

-

Old House Journal

Learn how to restore, repair, update, and decorate your home.

Subscribe Now- X

Membership & Magazine

- Online Archive

- Start Free Trial

- Magazine Subscription

- Magazine Renewal

- Gift a Subscription

- Customer Support

- Privacy Preferences

- About

- Contact

- Advertise

- Careers

- Terms of Service

- Site Map

- Do not sell or share my information

- Privacy Policy

- Accessibility

- California Privacy Rights

© 2025 Active Interest Media. All rights reserved.

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

X X This is a dialog window which overlays the main content of the page. The modal window is a 'site map' of the most critical areas of the site. Pressing the Escape (ESC) button will close the modal and bring you back to where you were on the page. SearchMain Menu

- How-To

- Design

- Tools & Materials

- Restoration

- Video

- Blogs

- Forum

- Project Guides

- Reader Projects

- Magazine

- Members

- FHB House

Podcasts

- FHB Podcast

- ProTalk

Webinars

- Upcoming and On-Demand

Podcasts

- FHB Podcast

- ProTalk

Webinars

- Upcoming and On-Demand

Popular Topics

- Kitchens

- Business

- Bedrooms

- Roofs

- Architecture and Design

- Green Building

- Decks

- Framing

- Safety

- Remodeling

- Bathrooms

- Windows

- Tilework

- Ceilings

- HVAC

Magazine

- Current Issue

- Past Issues

- Magazine Index

- Subscribe

- Online Archive

- Author Guidelines

All Access

- Member Home

- Start Free Trial

- Gift Membership

Online Learning

- Courses

- Project Guides

- Reader Projects

- Podcast

More

- FHB Ambassadors

- FHB House

- Customer Support

Account

- Log In

- Join

Newsletter

Get home building tips, offers, and expert advice in your inbox

GoSigning you up...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. See all newsletters See all newslettersFollow

- X

- YouTube

- Tiktok

Join All Access

Become a member and get instant access to thousands of videos, how-tos, tool reviews, and design features.

Start Your Free TrialSubscribe

Start your subscription today and save up to 71%

Subscribe Toggle Caption Previous NextMembers get unlimited site access.

To unlock this page, Start a Free Trial

Already a member? Log in

Tag » How To Solder Copper Pipe Vertically

-

Solder Vertical Copper Pipes For Beginners - YouTube

-

Soldering Vertical Copper Pipes - Water Wicking And Basic Tools

-

Solder Copper Pipe Like Pro Vertical Connection - YouTube

-

How To Solder Copper Pipe Like A Pro (Tips & Tricks) | GOT2LEARN

-

How I Solder Vertical Copper Fittings Make Clean, Sealed, Sweat ...

-

How To Solder Vertical Fittings. House Restoration. - YouTube

-

How To Make Solder Flow Upwards | EHow

-

How To Solder Vertical Copper Pipe – 5 Easy Ways (Updated Guide ...

-

Vertical Soldering - Screwfix Community Forum

-

How To Solder Copper Pipes - The Home Depot

-

How To Solder Copper Pipe : 8 Steps (with Pictures) - Instructables

-

Soldering Copper Pipe - Love Plumbing & Remodel