Volkswagen Golf 4 Bora (1998-2005)

- Log In

- Sign Up

- more

- About

- Press

- Papers

- Terms

- Privacy

- Copyright

- We're Hiring!

- Help Center

- less

Outline

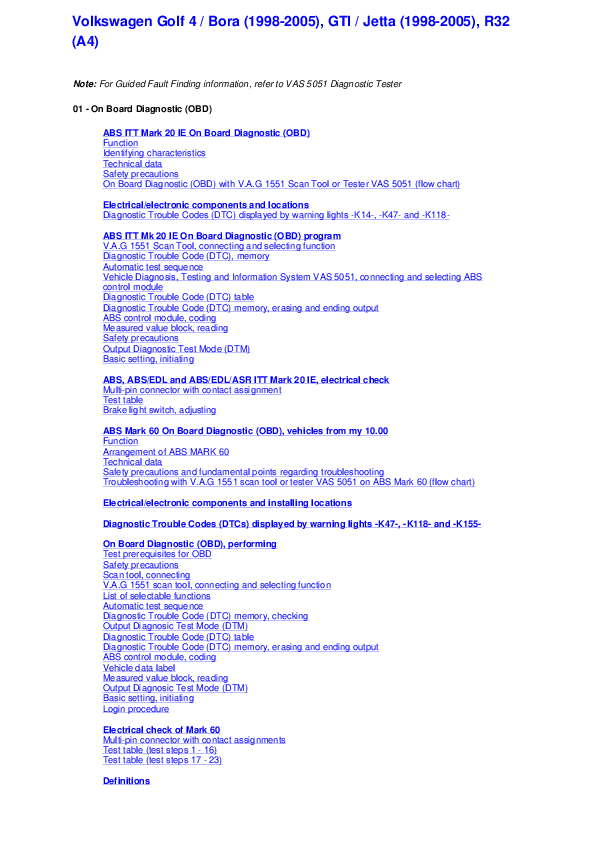

keyboard_arrow_downTitleAbstractData Bus for EngineSystem Designation (Esp)Rapid Data Transfer Q 02 -Check DTC MemoryRapid Data Transfer Q 03 -Brake ElectronicsRapid Data Transfer Help Select Function XXRapid Data Transfer Q 05 Erase DTC MemoryRapid Data Transfer HelpRapid Data Transfer Q

Download Free PDF

Download Free PDFVolkswagen Golf 4 Bora (1998-2005) Danko Carvisibility

Danko Carvisibility…

description339 pages

descriptionSee full PDFdownloadDownload PDF bookmarkSave to LibraryshareShareclose

Sign up for access to the world's latest research

Sign up for freearrow_forwardcheckGet notified about relevant paperscheckSave papers to use in your researchcheckJoin the discussion with peerscheckTrack your impactAbstract

Electrical/electronic components and locations Diagnostic Trouble Codes (DTC) displayed by warning lights-K14- ,-K47-and-K118

... Read moreSee full PDFdownloadDownload PDF

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Related papers

A New Method for Emission Control System Malfunction Detection During the Periodic Technical InspectionMarko RešetarProceedings of the 17th International Conference on Environmental Science and Technology, 2021

The paper shows a new method for detecting emission control system malfunction during periodic technical inspection (PTI). The on-board diagnostic (OBD) test results were collected and processed during the PTI of vehicles in Croatia in 2020. The study included petrol and diesel passenger cars that passed the tailpipe test and for which an OBD test ha d also been performed. In 11.5% of the tested cars, at least one stored diagnostic trouble code (DTC) was found. Due to the significant number of vehicles with identified DTCs, a new and more efficient method for the detection of potentially defective vehicles has been suggested. The introduction of the OBD test mandatory for all vehicles equipped with a European on-board diagnostic (EOBD) system is proposed. In addition to the existing OBD data, it is recommended to introduce the number of DTCs as mandatory, and such data should be relevant for passing the roadworthiness test.

downloadDownload free PDFView PDFchevron_rightSkoda kodiaq electrical system engJorge Angel López SánchezEsquema eléctrico del Skoda Kodiac.

downloadDownload free PDFView PDFchevron_rightRemote Long Distance Volkswagen Vehicles Diagnostics in GhanaLambert NtibreyRemote Vehicle Diagnostics, (RVD) has become a standard feature on present generation vehicles. Only an insignificant number (which can in fact be rounded up to non-existent) of auto mechanics in Ghana appreciate this technology and are centered in the big cities and in the main, Accra – Tema metropolis, and charging exorbitant fees since vehicle owners have no alternatives. Vehicle owners are suffering damages to their vehicles and the inconvenience associated with it. Towing service had to be invited in some cases get the vehicle back to Accra or Tema or invite diagnostics person to travel to the vehicle location to resolve the issue. Vehicle companies with such facilities will not readily make it available to vehicles not bought from them, at best not at a cheap price. Internet glitches and speed have put RVD at risk in Ghana for fear of damaging vehicle control systems. As such RVD is not being done for Volkswagen in Ghana though it is available elsewhere. High speed Internet access is required. Motivated to save computerized vehicle users the frustration and financial loss caused by faults on their vehicle that require computer diagnostics and to assist mechanics in performing computer diagnostics of vehicles while the vehicle are remotely located in their workshops far from the RVD centre, key technologies and standards for wireless, fixed-wireless and mobile networks and their properties that are essential for supporting RVD services are identified and discussed. The structural and service-oriented parameters that influence the development of mobile service infrastructures are reviewed. The drivers for ICT market and business development are discussed and combined with knowledge on technological solutions to analyze a systemic innovation business model for Remote Vehicle Diagnostics in Ghana.The Methodology applied is by desk study, literature review of Remote Vehicle Diagnostics (RVD) and standards, and Stakeholders interviews. The architecture is analyzed and prepared. Broadband technologies are discussed and compared, broadband infrastructures in Ghana are reviewed and recommendations made the broadband infrastructure for RVD in Ghana. Market drivers and barriers are discussed and based on that a systemic innovation approach is used to discuss the business model targeted towards setting up a business entity to provide Remote Vehicle Diagnostics service for Volkswagen.

downloadDownload free PDFView PDFchevron_rightAutomobile electrical and electronic sysgary sanchezPreface ix Introduction to the third edition x Acknowledgements xi 1 Development of the automobile electrical system 1.1 A short history 1.2 Where next? 1.3 Self-assessment 2 Electrical and electronic principles 2.1 Safe working practices 2.2 Basic electrical principles 2.3 Electronic components and circuits 2.4 Digital electronics 2.5 Microprocessor systems 2.6 Measurement 2.7 Sensors and actuators 2.8 New developments 2.9 Diagnostics-electronics, sensors and actuators 2.10 New developments in electronic systems 2.11 Self-assessment 3 Tools and test equipment 3.1 Basic equipment 3.2 Multimeters 3.3 Specialist equipment 3.4 Dedicated equipment 3.5 On-board diagnostics 3.6 Case studies 3.7 Diagnostic procedures 3.8 New developments in test equipment 3.9 Self-assessment 4 Electrical systems and circuits 4.1 The systems approach 4.2 Electrical wiring, terminals and switching 4.3 Multiplexed wiring systems 4.4 Circuit diagrams and symbols 4.5 Case study 4.6 Electromagnetic compatibility (EMC) 4.7 New developments in systems and circuits 4.8 Self-assessment 5 Batteries 5.1 Vehicle batteries 5.2 Lead-acid batteries 5.3 Maintenance and charging 5.4 Diagnosing lead-acid battery faults 5.5 Advanced battery technology 5.6 Developments in electrical storage 5.7 New developments in batteries 5.8 Self-assessment 6 Charging systems 6.1 Requirements of the charging system 6.2 Charging system principles 6.3 Alternators and charging circuits 6.4 Case studies 6.5 Diagnosing charging system faults 6.6 Advanced charging system technology 6.7 New developments in charging systems 6.8 Self-assessment 7 Starting systems 7.1 Requirements of the starting system 7.2 Starter motors and circuits 7.3 Types of starter motor 7.4 Case studies 7.5 Diagnosing starting system faults 7.6 Advanced starting system technology 7.7 New developments in starting systems 7.8 Self-assessment 8 Ignition systems 8.1 Ignition fundamentals 8.2 Electronic ignition 8.3 Programmed ignition 8.4 Distributorless ignition 8.5 Direct ignition 8.6 Spark-plugs 8.7 Case studies 8.8 Diagnosing ignition system faults 8.9 Advanced ignition technology 8.10 New developments in ignition systems 8.11 Self-assessment 9 Electronic fuel control 9.1 Combustion 9.2 Engine fuelling and exhaust emissions 9.3 Electronic control of carburation 9.4 Fuel injection 9.5 Diesel fuel injection 9.6 Case studies 9.7 Diagnosing fuel control system faults 9.8 Advanced fuel control technology 9.9 New developments 9.10 Self-assessment 10 Engine management 10.1 Combined ignition and fuel management 10.2 Exhaust emission control 10.3 Control of diesel emissions 10.4 Complete vehicle control systems 10.5 Case study-Mitsubishi GDI vi Contents 10.6 Case study-Bosch 10.7 Diagnosing engine management system faults 10.8 Advanced engine management technology 10.9 New developments in engine management 10.10 Self-assessment Introduction to the third edition I am very grateful to the following companies who have supplied information and/or permission to reproduce photographs and/or diagrams, figure numbers are as listed:

downloadDownload free PDFView PDFchevron_rightSection C -Electrics C -134 C -134 Fault Finding JCB Service Masternovvie riezkyService Master is a gateway application allowing a large number of Vehicle Support Applications to be linked using one familiar interface. The interface acts as a graphical tool for selecting the target vehicle from a database of Vehicle Families and triggering the particular Service Tool Application desired. This removes the need for a user to 'remember' every individual service tool available and select which one is intended for a particular machine. The Service Master also provides several key features that will accompany all JCB projects, a Multi Language editing tool that provides a means of individual text string translation for all JCB applications and the means to select a localised language translation for each JCB application.

downloadDownload free PDFView PDFchevron_right

- Explore

- Papers

- Topics

- Features

- Mentions

- Analytics

- PDF Packages

- Advanced Search

- Search Alerts

- Journals

- Academia.edu Journals

- My submissions

- Reviewer Hub

- Why publish with us

- Testimonials

- Company

- About

- Careers

- Press

- Help Center

- Terms

- Privacy

- Copyright

- Content Policy

580 California St., Suite 400San Francisco, CA, 94104© 2026 Academia. All rights reserved

580 California St., Suite 400San Francisco, CA, 94104© 2026 Academia. All rights reserved Từ khóa » Vw Golf G251

-

Longitudinal Acceleration Sensor -G251- - Volkswagen Golf 4 1998 ...

-

01279 - Ross-Tech Wiki

-

VW Golf (1K) Brake Electronics (MK60) - Ross-Tech Wiki

-

1J0907651A Volkswagen Beetle Golf 4 ESP Lateral Acceleration ...

-

ESP,ABS. Longitudinal Acceleration Sensor (G251) Disassembled ...

-

Volkswagen Golf / Golf GTI / Jetta. Manual - Part 432

-

HELP: Acceleration Sensor G251 | Volkswagen Mark IV Forum

-

Golf 4mo, Resetting G200/G251 Sensors Not Working Correctly

-

Tuning-art G251 'Edition GTI' Tappetini Per VW Golf 5 6 Scirocco ...

-

Golf Mk4 - ABS, ADR, TCS, EDL, ESP - Workshop Manuals

-

1j0907651a - Niska Cena Na

-

Датчик продольного ускорения-G251 или чиним ABS - Golf - Drive2