Copper Alloy Data Sheet & Specs | Austral Wright Metals

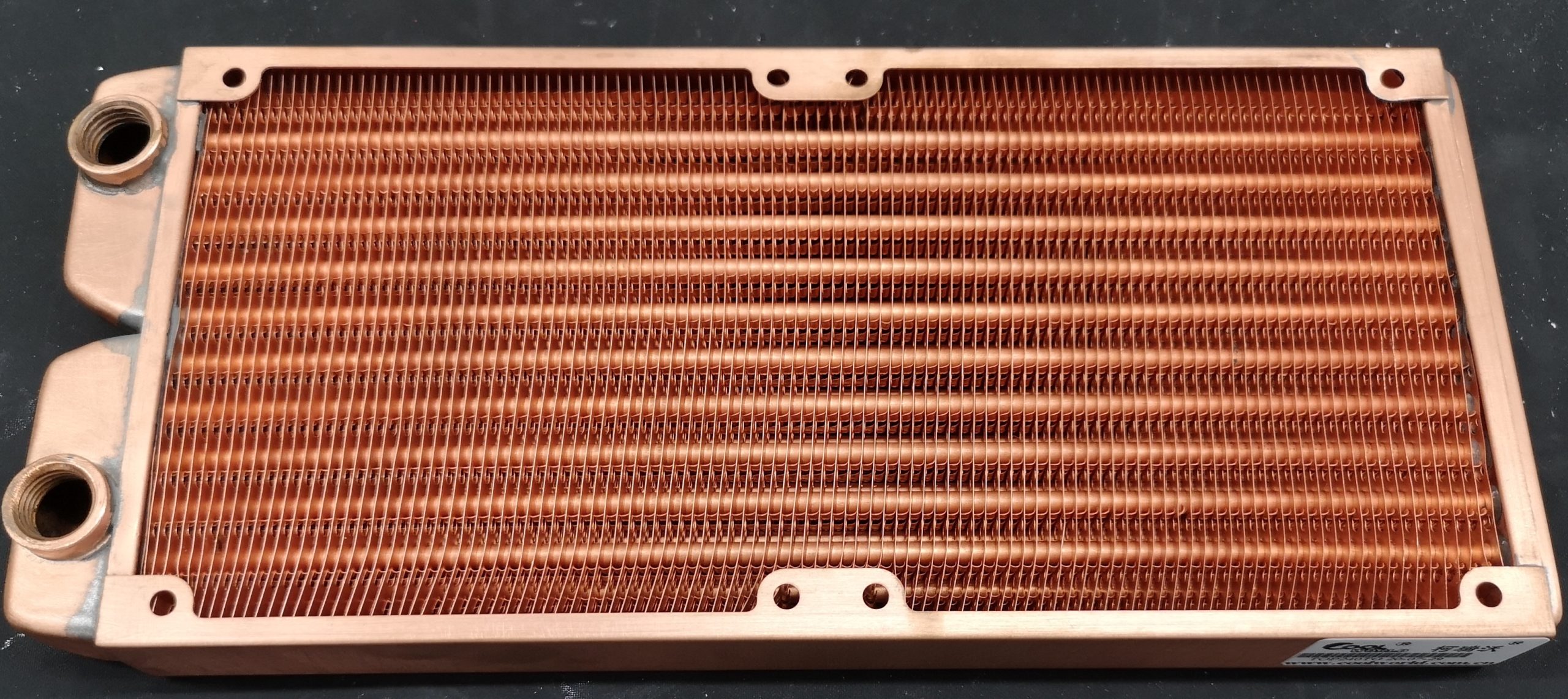

Copper alloy metals are used for their electrical and thermal conductivity, corrosion resistance, appearance and colour, and ease of working. They have the highest conductivity of the engineering metals and are very ductile and easy to braze, and generally to weld. Typical applications for alloys copper alloy include electrical wiring and fittings, busbars, heat exchangers, roofs, wall cladding, tubes for water, air and process equipment.

There are a number of copper alloy metals, with properties tailored for specific applications by judicious additions of traces of alloying elements. Whilst their is a vast range of copper alloys, such as brass, bronze, copper nickel and beryllium copper, copper metal is usually considered to contain no more than 0.1% of elements other than copper and silver.

Chemical Composition

AS2738.2 -1984

| UNS No | Code | AS No | Common Name | BSI | ISO | JIS | Cu | Others | Common End Uses |

| C10100 | OFE | 101 | Oxygen-free electronic | – | Cu-OFE | C 1011 | >99.99 | Oxygen < 5 ppm | Busbars, waveguides, lead in wire, glass to metal seals |

| C10200 | OF | 102 | Oxygen-free | C103 | Cu-OF | – | >99.95 | Oxygen < 10 ppm | Same as C10100 |

| C10300 | OFXLP | Oxygen-free extra low phosphorus | – | – | – | >99.95 | Phosphorus 0.001-0.005% | Same as C10100 | |

| C11000 | ETP | 110 | Electrolytic tough pitch | C101 | Cu-ETP | C1100 | >99.90 | Electrical conductors, gaskets, switches, terminals and connectors, transformers, electronic parts, ball floats, drawn and spun holloware | |

| C11600 | STP | 116 | Silver bearing tough pitch | – | Cu-Ag | – | >99.90 | Silver >0.085% | Electrical conductors, gaskets, switches, terminals and connectors, transformers, electronic parts |

| C12200 | DHP | 122 | Phosphorus deoxidised, high residual phosphorus | C106 | Cu-DHP | C 1220 | >99.90 | Phosphorus 0.015-0.040% | Tubing, heat exchangers, roofing, guttering and rainwater goods, facades |

| C14210 | DPA | 142 | Phosphorus deoxidised arsenical | C107 | – | – | >99.90 | Similar to C12200, contains arsenic to inhibit aqueous corrosion. | |

| C14400 | – | 144 | Tin-copper radiator strip | – | – | – | >99.90 | Phosphorus 0.013-0.025% Tin 0.10-0.20% | Automotive Radiators |

| C14700 | – | 147 | Sulphur bearing | C111 | – | – | >99.90 | Sulphur 0.20-0.50% | Machined copper components |

Electrical Conductivity of Copper Alloy

The electrical conductivity of copper alloy is often used as a benchmark of purity. The highest conductivity is obtained with pure copper. For ease of comparison, the conductivity of the purest commercial copper was set as the International Annealed Copper Standard (IACS) some years ago. 100% IACS corresponds to 0.5800 microhm?¹.cm?¹. Modern refining techniques now routinely produce copper of higher purity, which exceeds 100% IACS.

C11000

Electrolytic tough pitch copper, is the most commonly used metal in the group, with electrical conductivity of 100% IACS or better. It is made by melting cathode copper in a moderately reducing atmosphere, and may contain up to about 0.05% of oxygen as cuprous oxide. When heated above about 370°C in the presence of hydrogen (e.g. a gas flame) it may become hydrogen embrittled. C11000 is unsuitable for gas welding and high temperature brazing.

C10100 and C10200

Oxygen-free copper alloys, are made by melting cathode copper in low hydrogen, reducing conditions, without the addition of a deoxidising agent. These metals have high conductivity, exceptionally high ductility, low gas permeability, freedom from hydrogen embrittlement and low outgassing in a vacuum.

C10300

Oxygen-free extra low phosphorus copper alloy, is made by melting cathode copper under less critical conditions, deoxidising with phosphorus and controlling for a low residual phosphorus. Mechanical properties are similar to C10100 and C10200 at lower cost.

C11600

Silver bearing tough pitch copper alloys, are used where resistance to softening in the cold-worked condition above about 200°C is required. Silver does not reduce the conductivity of the copper significantly.

C12200

Phosphorus deoxidised copper, has been made weldable and brazeable by deoxidising with phosphorus. It is used for flat products, tubing and similar applications. Phosphorus significantly reduces the conductivity, which may go as low as 70% IACS. C14210, Phosphorus deoxidised arsenical copper alloys, also contains a small quantity of arsenic, which raises the softening temperature and significantly improves corrosion resistance in waters.

C14700

Sulphur bearing copper, has a sulphur addition to improve machinability. The reduction of conductivity is slight, to about 95% IACS.

Advantages of copper alloy

Copper alloys have numerous benefits and in particular are a crucial element within electrical distribution systems, especially when simplifying the process of electrical power distribution, reducing overall cost, and allowing for greater flexibility. Their superior electrical and thermal conductivity is only matched by silver, making it a much more economical option.

Whilst copper is most commonly associated with electrical applications, it is in fact more widely used in the building sector. It’s longevity, corrosion resistance and aesthetic appearance makes copper alloy a preferred metal for roofing, cladding and rainwater goods.

Australian Product Specifications

| Specification | Product Form |

| AS1566 | Rolled flat products |

| AS1567 | Wrought rods, bars & sections |

| AS1568 | Forging stock & forgings |

| AS1569 | Seamless tubes for heat exchangers |

| AS1571 | Seamless tubes for air conditioning & refrigeration |

| AS1572 | Seamless tubes for engineering purposes |

ASTM Product Specifications

| Number | Title | C10100 | C10200 | C11000 | C11600 | C12200 | C14700 |

| B5 | High Conductivity Tough Pitch Copper Refinery Shapes | ? | ? | ? | |||

| B42 | Seamless Copper Pipe, Standard Sizes | ? | ? | ||||

| B68 | Seamless Copper Tube, Bright Annealed | ? | ? | ||||

| B75 | Seamless Copper Tube | ? | ? | ? | |||

| B88 | Seamless Copper Water Tube | ? | |||||

| B111 | Copper and Copper Alloy Seamless Condenser Tubes and Ferrule Stock | ? | ? | ? | |||

| B124 | Copper and Copper Alloy Forging Rod, Bar and Shapes | ? | ? | ||||

| B152 | Copper Sheet, Strip, Plate, and Rolled Bar | ? | ? | ? | ? | ? | |

| B187 | Copper Bar, Bus Bar, Rod and Shapes | ? | ? | ? | ? | ? | |

| B188 | Seamless Copper Bus Pipe and Tube | ? | ? | ? | ? | ||

| B280 | Seamless Copper Tube for Air Conditioning and Refrigeration Field Service | ? | |||||

| B283 | Copper and Copper Alloy Die Forgings (Hot Pressed) | ? | ? | ||||

| B301 | Free Cutting Copper Rod and Bar | ? | |||||

| B302 | Threadless Copper Pipe | ? | |||||

| B306 | Copper Drainage Tube (DWV) | ? | |||||

| B359 | Copper and Copper Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins | ? | ? | ? | |||

| B360 | Hard Drawn Copper Capillary Tube for Restrictor Applications | ? | |||||

| B372 | Seamless Copper and Copper Alloy Rectangular Waveguide Tube | ? | |||||

| B379 | Phosphorized Coppers Refinery Shapes | ? | |||||

| B395 | U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes | ? | ? | ||||

| B447 | Welded Copper Tube | ? | ? | ? | ? | ||

| B543 | Welded Copper and Copper Alloy Heat Exchanger Tube | ? | |||||

| B577 | Detection of cuprous Oxide (Hydrogen Embrittlement Susceptibility) in copper | ? | ? | ? | ? | ? | ? |

| B640 | Welded Copper and Copper Alloy Tube for Air Conditioning and Refrigeration Service | ? | ? | ? | |||

| B694 | Copper, Copper Alloy and Copper Clad Stainless Steel (CCS) and Copper Clad Alloy Steel (CAS) and Strip for Electrical Cable Shielding | ? | |||||

| B698 | Seamless Copper and Copper Alloy Plumbing Pipe and Tube | ? | ? | ||||

| B743 | Seamless Copper Tube in Coils | ? | ? | ||||

| B837 | Seamless Copper Tube for Natural Gas and Liquified Petroleum (LP) Gas Fuel Distribution Systems | ? |

Từ khóa » C11000 Vs C10200

-

C10200 Copper Vs. C11000 Copper

-

OS050 C11000 Copper Vs. C10200 Copper

-

Oxygen-free Copper - Wikipedia

-

[PDF] Copper And Copper Alloys | MWS Wire

-

Copper Grades - Total Materia

-

[PDF] Wrought Copper Alloys: Coppers (C10100 - C15999)

-

C10200 Alloy

-

Oxygen Free Copper, Tough Pitch Copper, Phosphorus Deoxidized ...

-

C10200 Copper Tubing - Atlas Bronze

-

China C11000 C10200 T2 Pure Copper Flat Bar

-

China Red Cu-of Copper Plate (C1100 C11000 C10200 Tu1 Tu2)